20kV transformer feeder cable

Typical calculations for a 20kV transformer feeder cable are presented below. After correct cable voltage classification the following considerations apply:

Consider a 20/3.3 kV, 12.5 MVA transformer to be fed by direct buried, 3 core XLPE, SWA, PVC, copper conductor cable.

1. Cable current carrying capacity

Transformer full load current is calculated by:

Ifull-load = 12.5 × 106 / 1.73 × 20 × 103 = 361 A

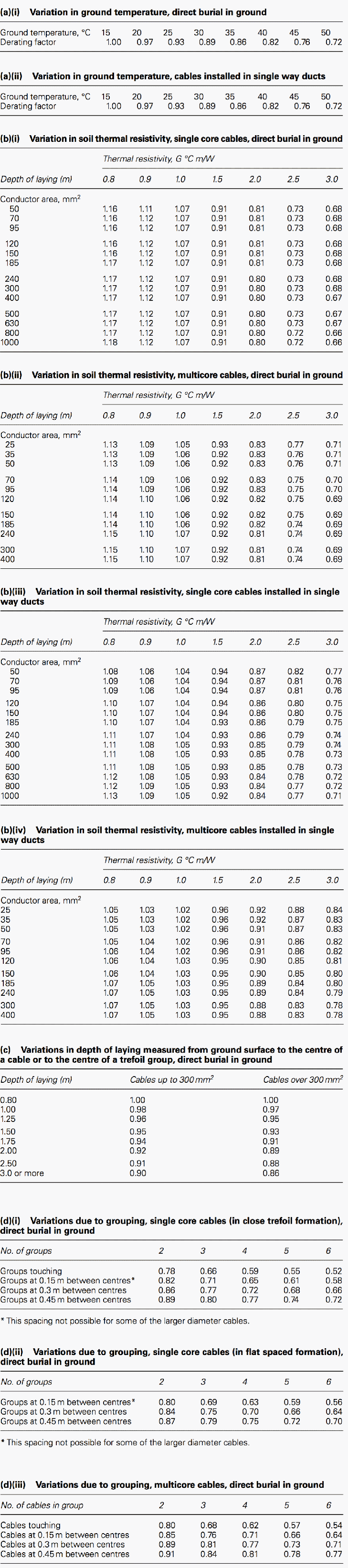

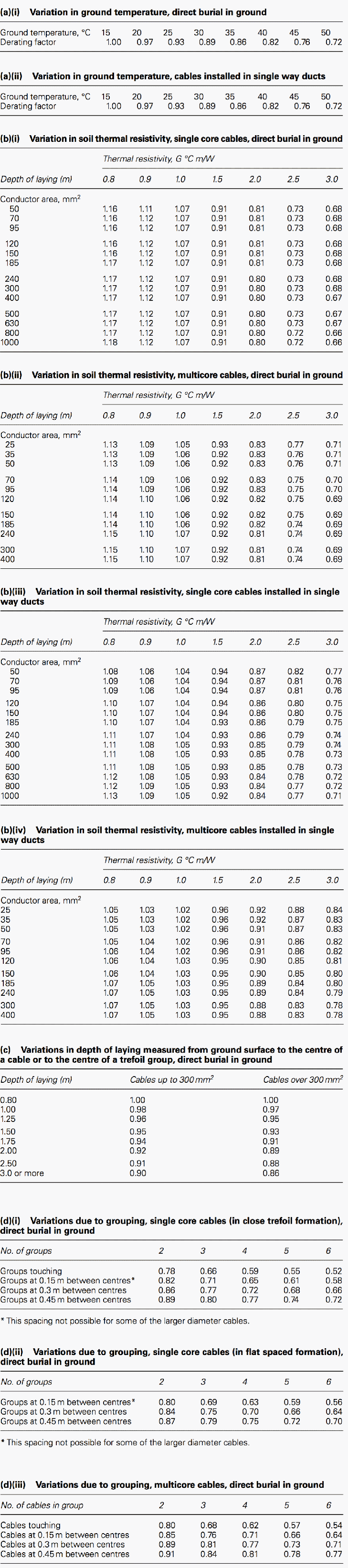

Don’t forget derating factors… Manufacturers provide data sheets for cables including appropriate derating factors based upon IEC 60287 (Table 1). For a ground temperature at depth of laying of 20°C, the derating factor is 0.97.

Therefore subsequent current rating of cable to be 361 / 0.97 × 0.84 = 443 A

From manufacturers tables selected cable size is 240 mm2.

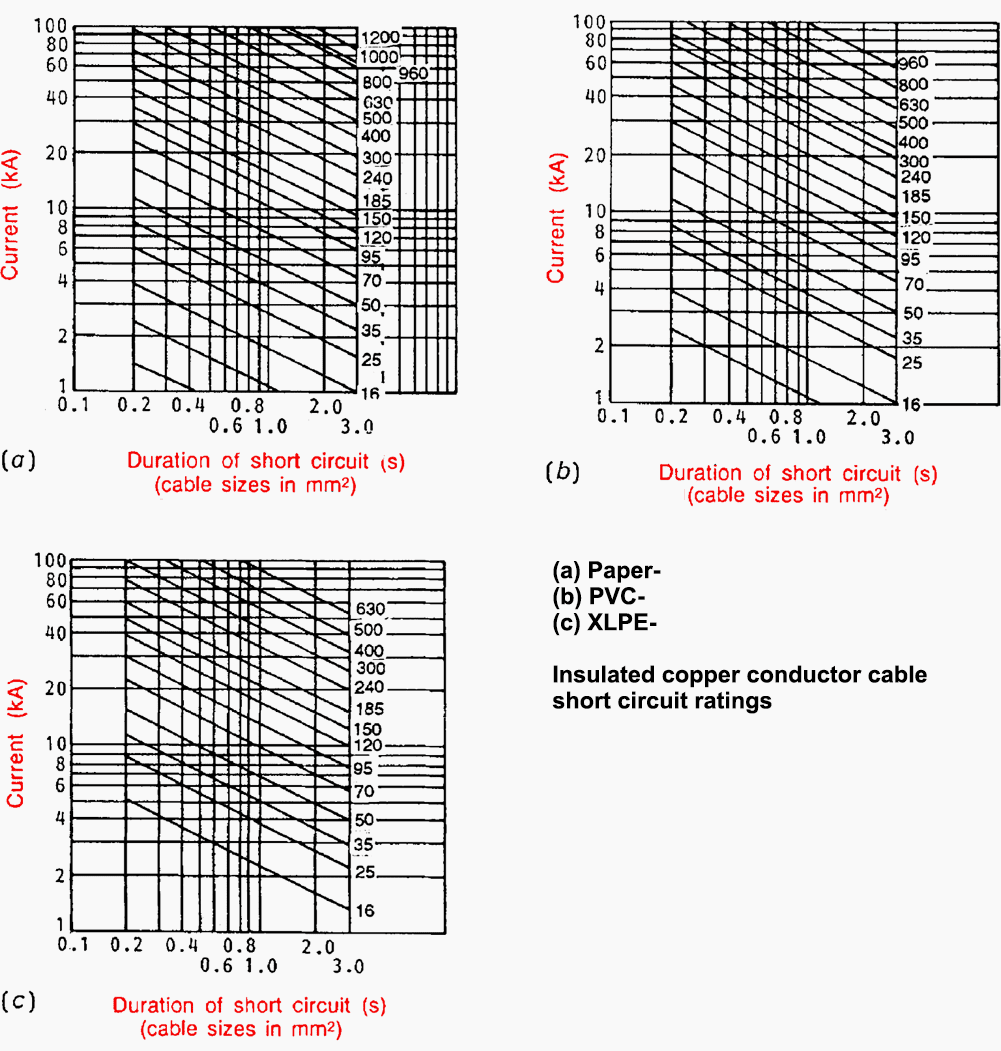

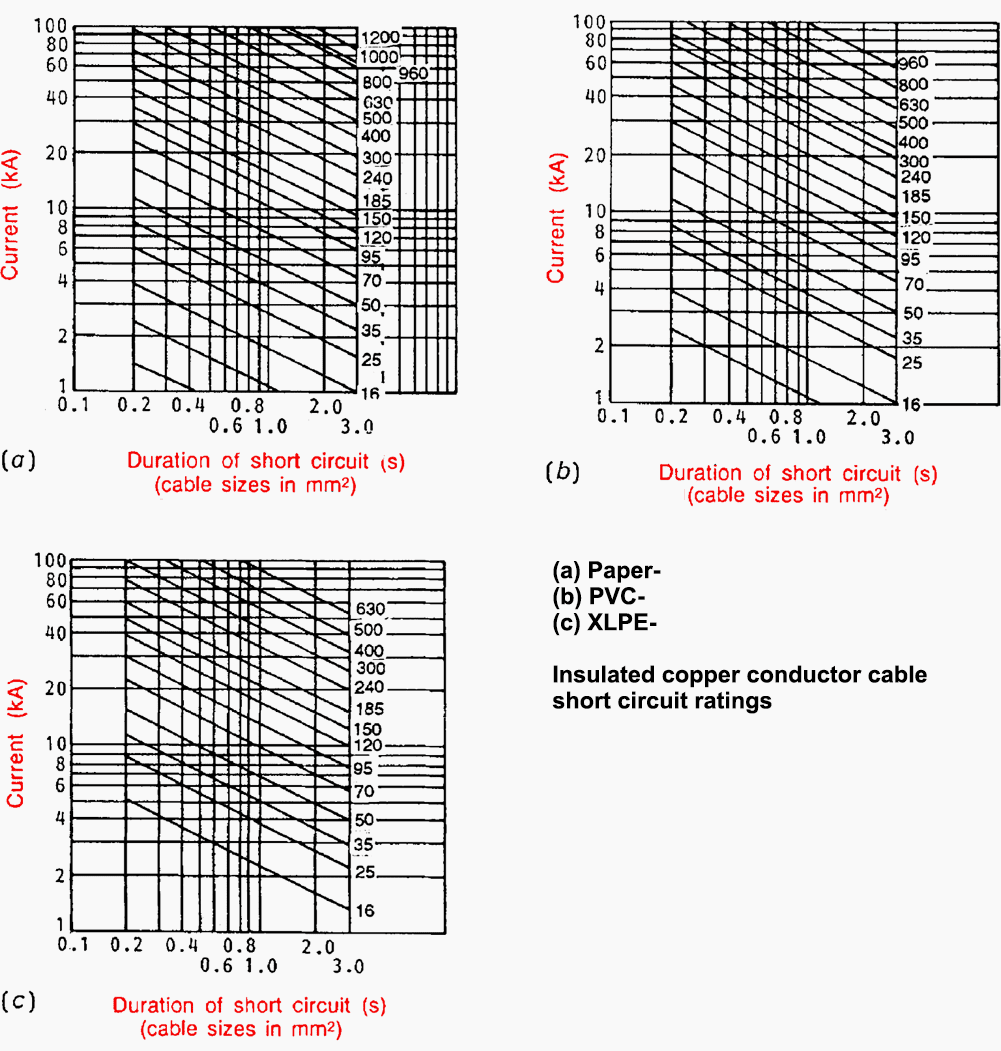

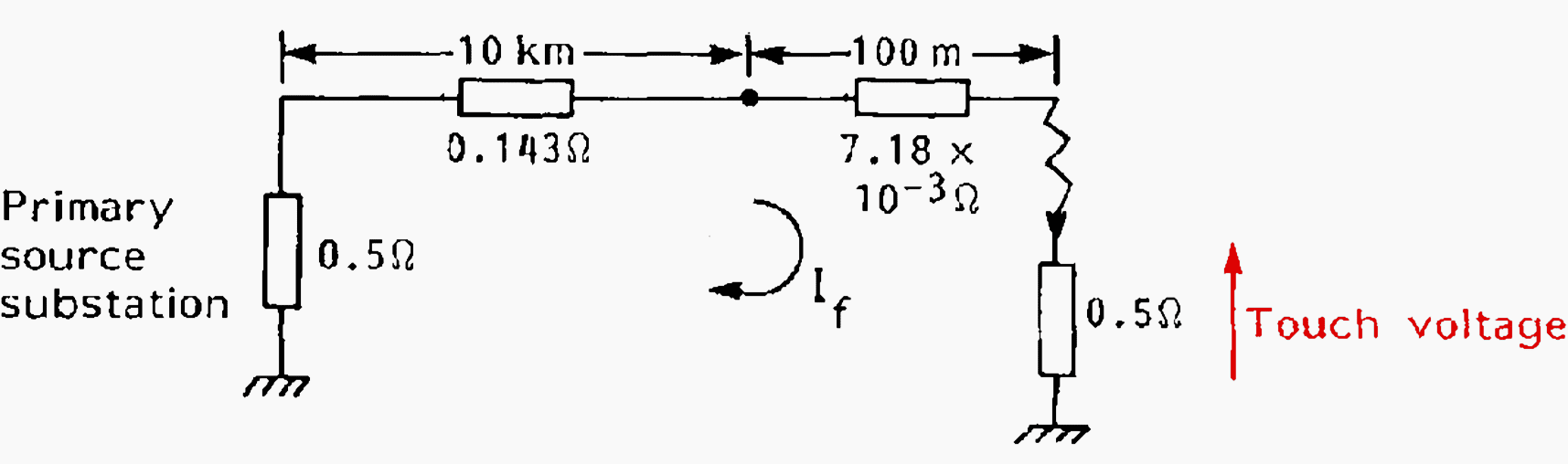

2. Short circuit rating

The maximum system fault level in this application is 8.41 kA. From standard IEC 60364-5-54 (Electrical Installations In Buildings – Earthing arrangements, protective conductors and protective bonding conductors):

Isc = K × A / √t

Where:

- K – constant, 143 for XLPE cable

- A – cable cross-section, 240 mm2 based on current carrying capacity

- t – short circuit duration, for MV cables use 1 second

Isc = 240 × 143 / √1 = 34.4 kA

Note tables are conservative and assume a fully loaded cable. At the initiation of the fault conductor temperature is 90°C and at the end of the fault conductor temperature is 250°C.

3. Voltage drop (Vd)

Consider a 100 m route length of cable with resistance, R = 0.0982 Ω/km and inductive reactance, XL = 0.097 Ω/km. At full load current, Ifl = 361 A at 0.85 power factor the cable voltage drop over a 100 m cable length,

Vd = Ifl × XL × sinφ + Ifl × R × cosφ volts

Vd = (361 × 0.097 × 0.53 + 361 × 0.0982 × 0.85) × 100 / 1000

Vd = (18.56 + 30.13) ×100 / 1000

Vd = 4.87 V

Vd = 0.042%

- At 20 kV the voltage drop is negligible over such a short length of cable.

- IEE Wiring Regulations require a voltage drop for any particular cable run to be such that the total voltage drop in the circuit of which the cable forms part does not exceed 2½% of the nominal supply voltage, i.e. 10.4 volts for a three phase 415 V supply and 6 volts for a single phase 240 V supply.

- Industrial plant users may use different specifications and apply 5% (or even 10%) under no load to full load conditions and perhaps 20% at motor terminals under motor starting conditions.

- Manufacturers data for building services installations is often expressed in terms of voltage drop (volts) for a current of 1 ampere for a 1 meter run of a particular cable size.

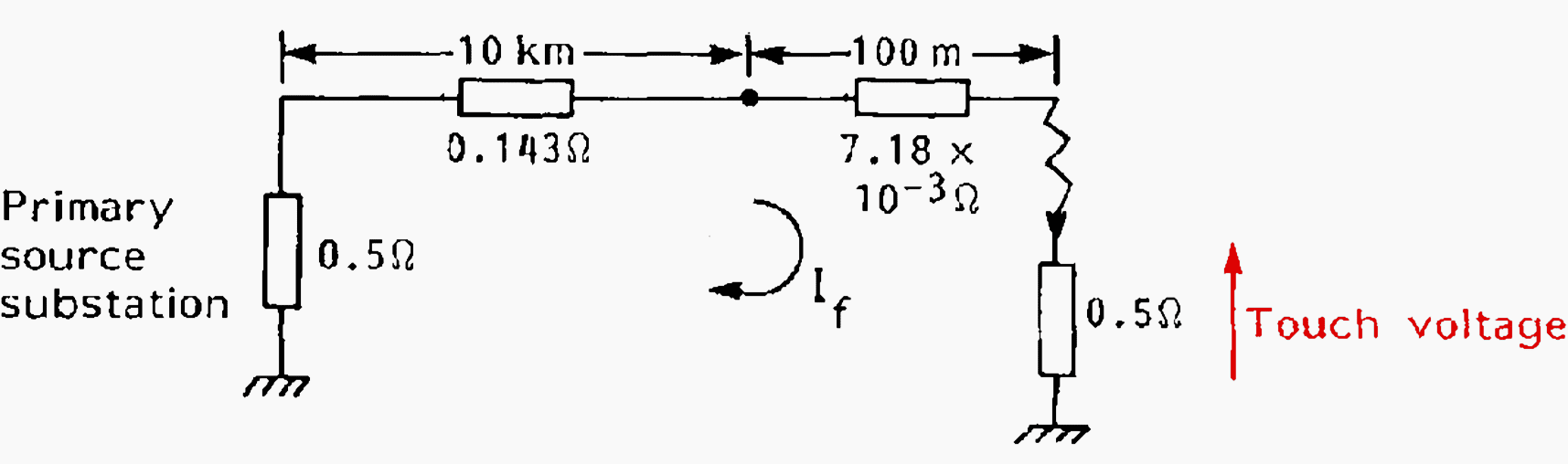

4. Earth loop impedance

For building services work it is important with small cross-section wiring and low fault levels to ensure that sufficient earth fault current flows to trip the MCB or fuse protection. For distribution power networks with more sophisticated protection the check is still necessary and allows the calculation of the likely touch voltages arising from the earth fault.

This in turn can then be checked against the allowable fault duration to avoid danger. See this article for a consideration of the design criteria associated with touch and step potentials.

Criteria #1 – Consider the earthing resistance at the source substation 0.5 .

Criteria #2 – The source substation 20 kV neutral is approximately 10 km from the 100 m cable under consideration. In addition parallel copper conductor earth cable is run to supplement and improve power cable armour resistance values from equipment back to the primary substation infeed neutral.

Criteria #3 – The combined resistance of the 100 m, 240 mm2, cable armour (0.028 Ω / 100 m) and in parallel 2 × 95 mm2 copper supplementary earth cables (0.00965 Ω /100 m) = 7.18 × 10-3 Ω.

Criteria #4 – Consider the earthing resistance at the cable fault to be 0.5.

Criteria #5 – The effective earth circuit is shown in Figure 2. The effective primary substation neutral-to-fault cable resistance 0.15.

Criteria #6 – The maximum earth fault current at 20 kV has to be determined. Sometimes this is limited by a neutral earthing resistor and the maximum limited current may be taken for calculation. Maximum earth fault current for this calculation is 1000 A.

For a fault to earth at the end of the 100 m cable, 10 km from the primary power infeed the fault current,

If = (1000 × 0.15) / (1 + 0.15) = 131 A

Therefore touch voltage to earth at the cable fault 131 × 0.5 = 65.3 V

APPENDIX – Derating factors based on IEC 60287

Reference // Transmission and Distribution Electrical Engineering by Dr C. R. Bayliss CEng FIET and B. J. Hardy ACGI CEng FIET

edvard, i think when you derate, you multiply the full load current by the derating factor, and not by dividing

4000 kva Trf how much sqmm HT cable required sir for 11kv

hello dear sir.. please tell me I whant to know 33kv 400v 1600KVA transformer what is the sutabel for cable size.

I think Hv side 240sqmm.

please briefly explained

11kV rated Cable,

MV Cable size As per short circuit is 279.7mm2.

2 x 3C x 185 mm2 cable can be selected?

3C x 300mm2 cable don’t want to be selected because of cable dia.

Current carrying capacity is ok.

Ifull-load = 12.5 × 106 / 1.73 × 20 × 103 = 361 A

Don’t you need a 125% conductor protection here before you apply derating factors?

Can you explain how to calculate earth cable size for LV transformer for both neutral and body earthing in the TN-S system? Specially I want to know how to select the time in the adiabatic equation.

I have 2MVA 11/0.433KV GMT.I want to connect 1x500sq.mm XLPE/SWA/PVC copper cable. How many cables can i use per phase. What calculation is used

Dear sir,

Please tell me the between KW and KVA for example 1 machine has 30kva load capacity how we have to select the cable.kindly explain

Thanks & regards,

Shoaib Noor.

but how to calculate cable size for low voltage side

Can we take parallel runs into account for calculation in the calculation of short circuit current capacity?

In my case a feeder has to be selected for feeding 33KV, 31.5 ka, 1 sec rated panel, for a load of 20MW.

I have selected 2R, 33KV, 300SQMM, AL Conductor, XLPE Insulated cable to be installed in RCC trenches, over 2000m length.

As per manufacturer catalog 300sqmm Al, XLPE cable can cater 28 ka, as two runs are considered, I expect it can take care 31.5ka for 1sec.

It is requested to advice on the above.

For current 443 A, why you selected 240 sqmm? Can I see the manufacturer’s table that you referred? According to my knowledge, 150 sqmm of MV Cu/XLPE cable can carry about 500 A at free air from many cable makers.

Impossible ,150 sqm can not carry 500A as you said , max 400A. To which brand you are referring?

Edvard, thanks for the interesting post.

Referring the above, I think 150mm2 would be too small. Strictly according to IEC 60502, 300mm2 is required. However, the calculation for 240mm2 is only short by 7A, so in practice, you would likely be ok with 240mm2. This is reinforced with Edvards calculation based on manufacturer’s data which gives 240mm2.

I printed out my calculations for reference, and you can view them here:

https://mycableengineering.com/Portals/0/Support/edvard_240mm2.pdf

https://mycableengineering.com/Portals/0/Support/edvard_300mm2.pdf