Basics of Electromobility

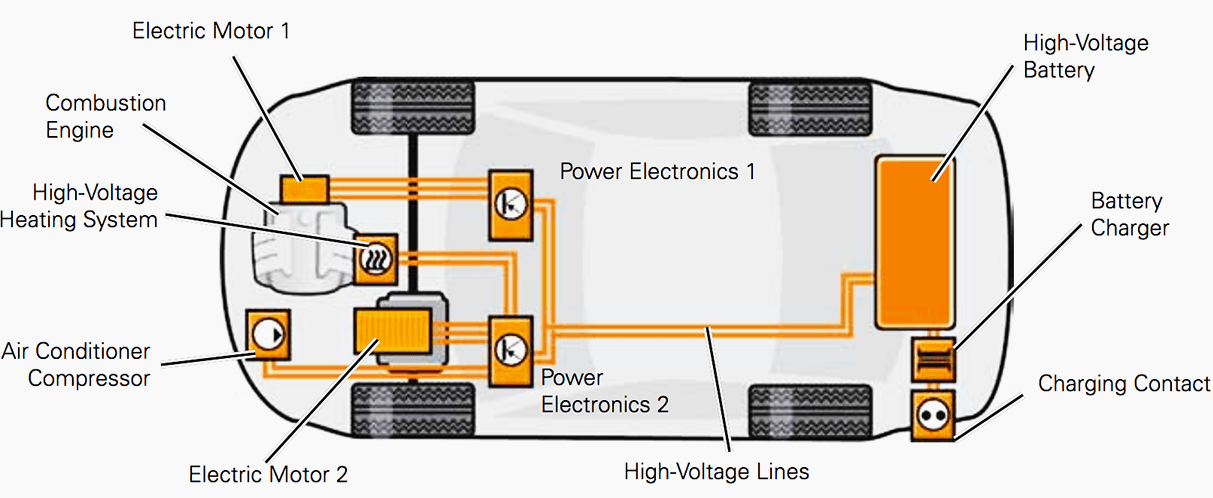

The term electric motor/generator is used instead of alternator, electric motor and starter. In principle, any electric motor can also be used as an alternator. When the electric motor/generator is driven mechanically, it supplies electrical energy as an alternator.

When the electric motor/generator is supplied with an electrical current, it works as a drive. Electric motors/generators used for propulsion are water-cooled. Air cooling would also be possible but complex due to space and the amount of heat generated.

In full hybrid vehicles (HEV), the electric motor/generator also functions as the starter for the combustion engine.

Several pairs of permanent magnets are located on the rotor in this synchronous motor. Since the three coils are supplied sequentially with a current, together they generate a rotating electrical field that causes the rotor to rotate when the electric motor/generator is used to drive the vehicle.

When used as an alternator, the movement of the rotor induces a three-phase alternating voltage in the coils that is transformed into a direct voltage for the high-voltage battery in the power electronics.

The advantage of synchronous motors compared with asynchronous motors is the more precise control of the motor in automobile applications.

Strengths of the Electric Motor/Generator

The electric motor/generator is very environmentally compatible thanks to the lack of noise and harmful emissions. The electric motor/generator responds quickly, has good acceleration figures and a high level of efficiency. In contrast to combustion engines, electric motors supply their nominal power steplessly over a broad rpm range.

The maximum torque is available even at low rpm (i.e. when pulling away) and only drops once the motor reaches very high speeds. As a result, neither a manually operated transmission, an automatic transmission nor a clutch are required.

The direction of rotation of an electric drive motor is freely selectable. It can turn clockwise to move the vehicle forwards and counter-clockwise to reverse it.

| Title: | Design and Function Basics of Electric Vehicles – Volkswagen Group of America, Inc. |

| Format: | |

| Size: | 1.5 MB |

| Pages: | 62 |

| Download: | Right here | Video Courses | Membership | Download Updates |

some of the animals such as Cats like sleeping behind the car. There are some concerns that they are not aware of the EV cars moving as it it too quiet

Please can somebody help me with the step by step material.

Thank you

show me the steps to take build an electric cars …. and back up information to help me.. I too want an electric car ….

May I have step step Project Plan for designing Electric Vehicle?

where is the step-by-step guide

But where is step-by-step guide?

Check the table where it mentions title, format, size, etc. – after the article. You have to download the pdf from the link “Right here”. It’s 62 pages

Informative and precise article.

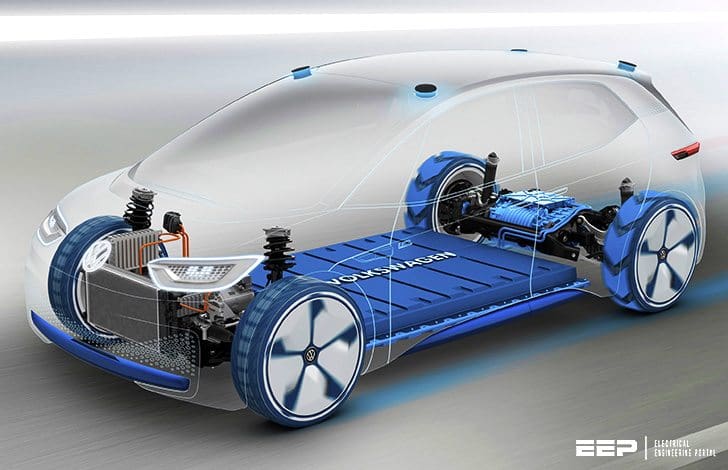

diagrammatic view explains many things easily

very informative and precise article.

diagram made things clear.

I think about the recharged on driving mode by using motors