Wastewater Treatment Plants (WWTP)

Motor management

Motors constitute the primary power load of a wastewater treatment plant (WWTP) and link a plant’s processes to its electrical network. Today’s plants face new challenges to boost efficiency and increase their returns on both CapEx and OpEx.

Intelligent motor starters (LV and MV) and motor control systems are one way to achieve this goal.

Impacts and applications

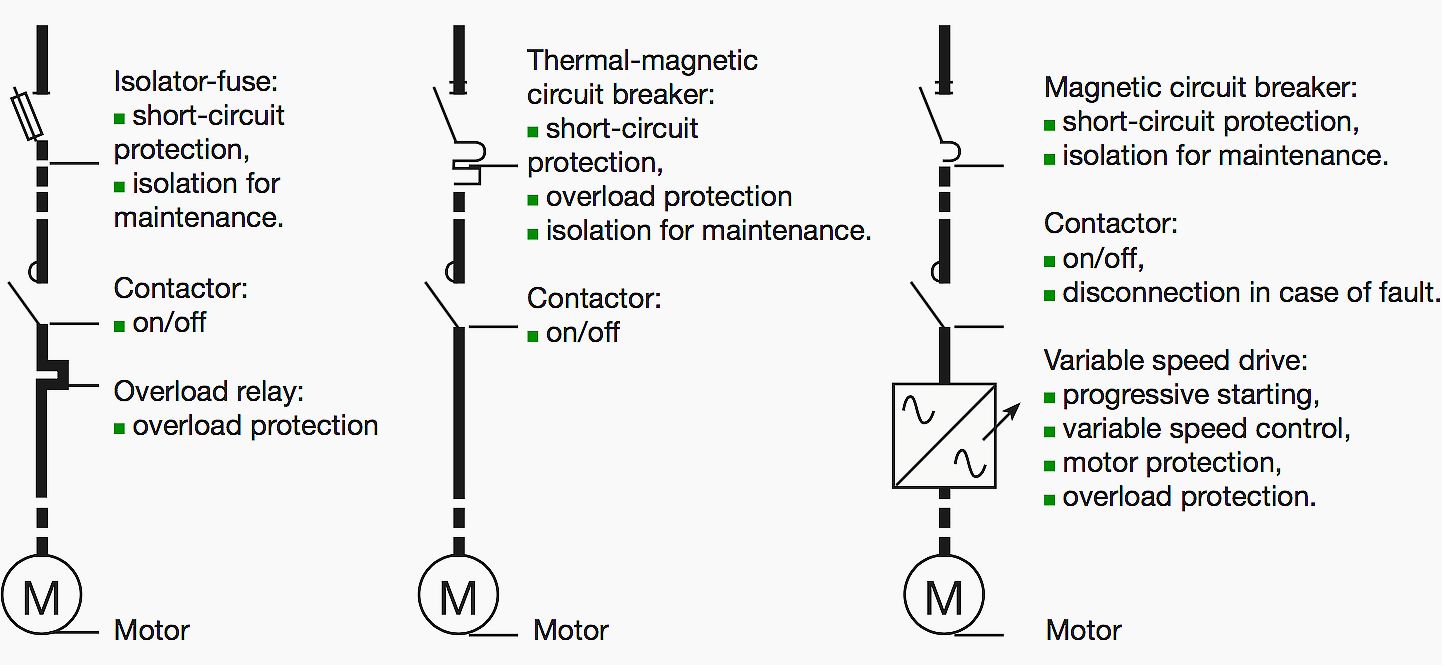

Because a single motor failure can mean costly downtime for a plant, plant managers need to ensure that their motors are adequately protected and have reliable control systems.

Motor protection and control is a plant-wide issue. It concerns not only a plant’s motors and processes but also operator safety, electrical technician safety (at the motor starter, electrical feed, and load levels via isolation and lockout), and the protection of the plant’s electrical network.

Recommended solutions

Conventional motor protection systems based on thermal overload protection cannot communicate with higher-level process control systems and consequently fail to meet the needs of today’s continuous process industries.

This is due to several factors //

First, motor failure can be triggered by a variety of incidents, such as an abnormal power load or supply, an insulation failure, incorrect wiring, or a number of external factors. Such incidents can cause motor burnout or other problems, each requiring a different response.

Second, protecting a motor by simply shutting it down is often impractical. Today’s plants need intelligent motor protection systems that can identify potential risks and alert operators to take action before a failure occurs.

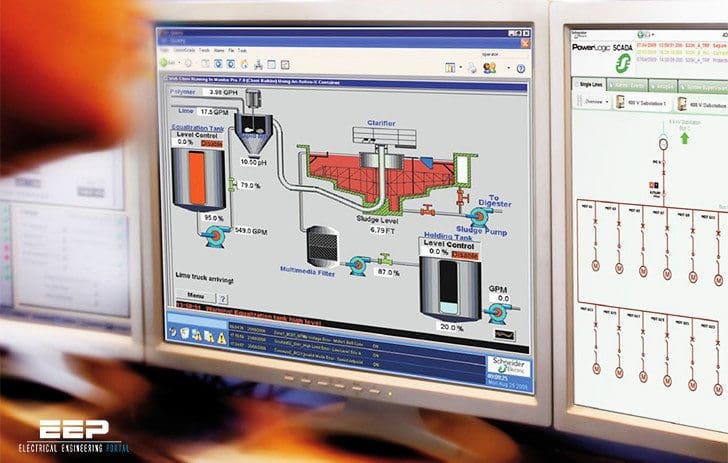

Third, motor protection systems must communicate with both process and power SCADA systems.

| Title: | Recommended electrical network design for efficient wastewater treatment plants – Schneider Electric |

| Format: | |

| Size: | 8.0 MB |

| Pages: | 50 |

| Download: | Right here | Video Courses | Membership | Download Updates |

I want to know about PLC and I am working in Steel plant. The machinery like slitter machine and Shearing machine, blanking machine these three machines are based on siemens drives, servo motor (unico)

Please share any documents regarding this

Thanks and regards

V.AGUSTIN ANBURAJ