Recommended minimum practice for preventive maintenance

Insulation //

Remove and clean interphase barriers. Clean all insulating materials with vacuum and/or clean lint free rags. If it is necessary to use cleaning solvents, use only solvents recommended by the manufacturer.

Inspect for (early) signs of corona, tracking, arcing, or thermal or physical damage.

Ensure that insulation is left clean and dry.

Contacts

Ensure that all contacts are clean, smooth, and in proper alignment. Ensure that spring pressures are maintained according to manufacturer’s specifications. On silver contacts, discoloration is not usually harmful unless caused by insulating deposits. Clean silver contacts with alcohol or silver cleaner using non-abrasive cloths.

Manually close breaker to check for proper wipe, contact pressure, contact alignment, and to ensure that all contacts make at approximately the same time.

Older breakers equipped with carbon contactors generally require very little maintenance. Examine for proper pressure, deterioration, or excessive dressing which may interfere with their proper operation.

Draw-out contacts on the circuit breaker and the stationary contacts in the cubicle should be cleaned and inspected for overheating, alignment, and broken or weak springs. Coat contact surfaces with contact lubricant to ease mating (see manufacturer’s recommendations).

Arc Interrupters

Clean all ceramic materials of loose dirt and examine for signs of moisture, make sure the assemblies are clean and dry. Examine for cracked or broken pieces. Dirt and arcing deposits may be removed by light sanding — do not use emery cloth or wire brushes which may leave conductive residue behind. Repair or replace as necessary.

Examine arc chutes for dirt and/or dust accumulations and clean as necessary. Dielectric testing of arc shields may be recommended by the manufacturer. Check air puffer for proper operation.

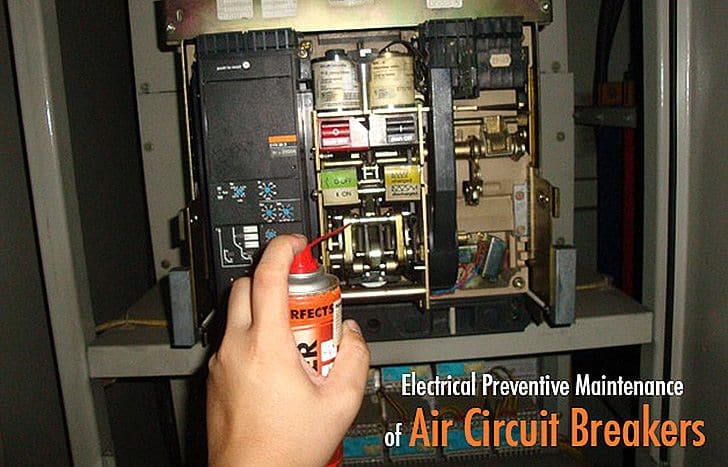

Operating Mechanism

Inspect for loose, broken, worn, or missing parts (consult manufacturer’s schematics for required parts). Examine for excessive wear of moving parts. Observe that operating mechanisms function properly without binding, hanging, or without delayed action.

Ensure any lubrication is done according to the manufacturer’s specifications.

Ensure mechanisms are clean, properly lubricated, and all bolts and screws are properly secured. Repair or replace as necessary.

Auxiliary Devices

Inspect operating devices for proper operation and general condition. Ensure all indicating devices are fully functional and properly set.

Protective relays and circuit breaker trip devices should be inspected and tested according to manufacturers’ specifications and applicable industry standards such as those issued by the Institute of Electrical and Electronics Engineers (IEEE) and the National Fire Protection Association (NFPA).

References:

- Standard for and electrical preventive maintenance (EPM) program – The Hartford Steam Boiler Inspection and Insurance Company

- Fuji Electric FA Components & Systems Catalogue

sir, i need training in Transformers and all types of breaker

I would like to receive training on mv maintenance and transformer protection relay.

hi sir is the air circuit breaker400A can manually push by hand? because its tripping without anu load or power supply what is the cause hope to subscribe soon thanks in advance

Lint-free rags should be used when cleaning a breaker because?

*lint attracts dust, which can cause tracking?

please let me know the correct answer please.

sir which is the best method for arc extingused at the high load

Thanks for sharing your blog with us.This blog shared all the functions of Circuit Breaker and its rated charachteristics.This blog has cleared all the concept of Air Circuit Breaker.L&T Electrical & Automation has some registered product.You may visit L&T Electrical & Automation

AIR CIRCUIT BREAKER CANT TURN ON AFTER ENERGIZE- PLS ADVISE

Please check your main moving mechanism parts. Some time it just need to regreasing or some oiling. See your environment. If dusty sure this will happened.

Yes, i am satisfy.

Hello Sir

My ACB now one terminal have been burn and it occur tree time , so how can i solve it ?

Some ACB the main moving contact or main fix contact can be replaced. If yes please do replace it. Easily you can see the damage. If there was some melted mark mean the damage is already there. If it just carbonise just clean it.

No only abb make only we changing opposition fixed and moving contact s

Hello Sir..What is function of the micrologic control.?

nice

DEAR SIR

HOW THE ACB GOT FEED INSIDE THE FRAME

Better still what to consider in other to improve the power factor of a plant .

Most of the plants were fitted with synchronous condenser or generator to cop up with power factor issue. Also, condensers are fitted at various places where inductive loads are located. While installing a new inductive machinery it is advisable to take its pf into consideration.

it educative to know you share such a deep insight, i would love to know what are the best and affordable ways of improving power factor of a plant?

Hello Sir,

Can we control kvar ratings of a power factor capacitor by varying voltage supplied to it, by varying the triggering of thyristors and thus control power factor in a more significant manner?