An increasing problem today with the use of more and more electronic equipment in our systems is the Electro Static Discharge (ESD). The main source of the problem is the wrong handling of electronic components, printed circuit boards, etc.

A component damaged by ESD has been exposed to a too high voltage level and today the components are much more sensitive depending on integration, which means more functions in the same capsule. The distances between the conductors are decreased and therefore the insulation distance will be at a minimum.

A value of 0.002 mm is common in modern integrated circuits.

Electro static charge is caused in three different ways:

- Rubbing of two surfaces to each other.

- Separation of two surfaces from each other, for example when removing a plastic cover from its contents.

- Induction caused by static electricity without any contact of the material.

Two type of faults and different circuits

The ESD damages are divided into two groups of faults: direct fault and latent defect. The direct faults are quite easy to detect since the component will not work at all and this is very often discovered

at the factory before shipping.

The latent defects can be very difficult to identify since the component is not working in a reliable way and the life length of the device may be reduced dramatically.

Fault generated by ESD Digital circuits:

- ”Ones” becomes ”zeros” and ”zeros” becomes ”ones” for no reason.

- No ”ones” or ”zeros” at all ( the circuit is dead).

Analogue circuits:

- Worsening accuracy of measuring

- Wrong voltage levels that require adjustments

- Malfunction

Electro static voltage levels

A voltage level of between 100-500 V can destroy any electronic components in principle. The most sensitive components can only withstand voltages between 25-170 V.

Sometimes it is possible to hear a ”click” sound when touching an object and that is typical ESD phenomena. When it is possible to hear that ”click” sound the voltage level is already at least 3,5 kV. Sometimes it is also possible to see a spark when touching an object and the voltage level is then at least 10 kV.

Below some values are given for typical Electro static charge:

- Walking on a wall-to-wall carpet: 10 – 20 kV

- Walking on a plastic floor (PVC): 2 – 5 kV

- Walking on an anti-static floor: 0 – 2 kV

- Lifting paper from a table: 5 – 35 kV

- Rising from a chair: 10 -25 kV

Protection against ESD damages

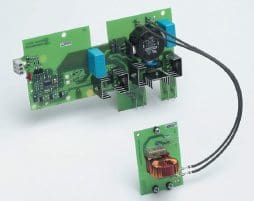

It is possible to reduce the risk of ESD to a minimum for the equipment. This is very important to remember when making service and/or repair with electronic components for example the printed circuit board on a softstarter.

Actions to prevent damages:

- Avoid charge if possible

- Always use a wrist strap or similar connected to ground potential when working with electrical components

- Always use the right type of package (ESD protected bags, etc.)

- Connect all machines and apparatus to ground potential

- High humidity

Nice to read the articles which are really nice , requesting for the subscription of the newsletter

Is there any instructions for use of ESD Apron?

How to use ESD aprons?

Any one who knows the equipment for releasing static energy,please kindly advise for me.