Introduction

A stepper motor is an electromechanical device which converts electrical pulses into discrete mechanical movements. The shaft or spindle of a stepper motor rotates in discrete step increments when electrical command pulses are applied to it in the proper sequence.

The motors rotation has several direct relationships to these applied input pulses. The sequence of the applied pulses is directly related to the direction of motor shafts rotation.

Stepper Motor Advantages and Disadvantages

Advantages

- The rotation angle of the motor is proportional to the input pulse.

- The motor has full torque at standstill (if the windings are energized)

- Precise positioning and repeatability of movement since good stepper motors have an accuracy of 3 – 5% of a step and this error is non cumulative from one step to the next.

- Excellent response to starting/stopping/reversing.

- Very reliable since there are no contact brushes in the motor. Therefore the life of the motor is simply dependant on the life of the bearing.

- The motors response to digital input pulses provides open-loop control, making the motor simpler and less costly to control.

- It is possible to achieve very low speed synchronous rotation with a load that is directly coupled to the shaft.

- A wide range of rotational speeds can be realized as the speed is proportional to the frequency of the input pulses.

Disadvantages

- Resonances can occur if not properly controlled.

- Not easy to operate at extremely high speeds.

Open Loop Operation

One of the most significant advantages of a stepper motor is its ability to be accurately controlled in an open loop system.

Your position is known simply by keeping track of the input step pulses.

Stepper Motor Types

There are three basic stepper motor types. They are:

- Variable-reluctance (VR)

- Permanent-magnet (PM)

- Hybrid (HB)

Variable-reluctance (VR)

This type of stepper motor has been around for a long time. It is probably the easiest to understand from a structural point of view.

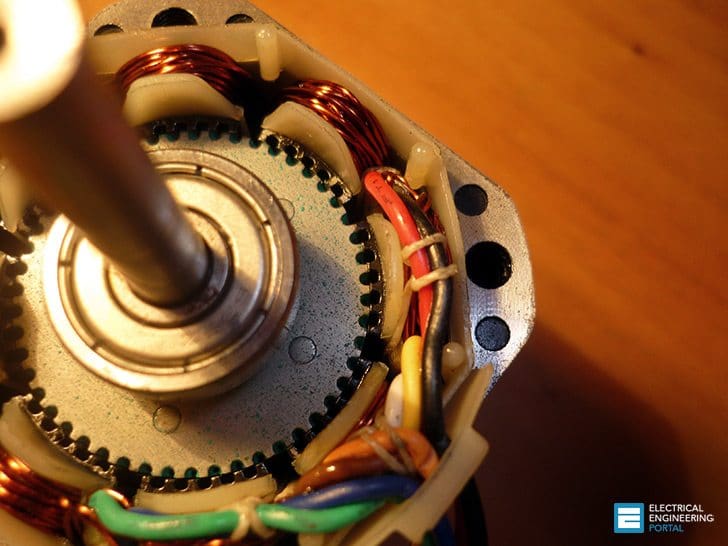

Figure 1 shows a cross section of a typical V.R. stepper motor.

This type of motor consists of a soft iron multi-toothed rotor and a wound stator. When the stator windings are energized with DC current the poles become magnetized. Rotation occurs when the rotor teeth are attracted to the energized stator poles.

Permanent Magnet (PM)

Often referred to as a “tin can” or “canstock” motor the permanent magnet step motor is a low cost and low resolution type motor with typical

step angles of 7.5°to 15°.

(48 – 24 steps/revolution) PM motors as the name implies have permanent magnets added to the motor structure.

These magnetized rotor poles provide an increased magnetic flux intensity and because of this the PM motor exhibits improved torque characteristics when compared with the VR type.

Hybrid (HB)

The hybrid stepper motor is more expensive than the PM stepper motor, but provides better performance with respect to step resolution, torque and speed.

Typical step angles for the HB stepper motor range from 3.6°to 0.9° (100 – 400 steps per revolution).

The rotor is multi-toothed like the VR motor and contains an axially magnetized concentric magnet around its shaft. The teeth on the rotor provide an even better path which helps guide the magnetic flux to preferred locations in the airgap. This further increases the detent, holding and dynamic torque characteristics of the motor when compared with both the VR and PM types.

The two most commonly used types of stepper motors are the permanent magnet and the hybrid types.

Make the right choice

If a designer is not sure which type will best fit his applications requirements he should first evaluate the PM type as it is normally several times less expensive. If not then the hybrid motor may be the right choice.

There also excist some special stepper motor designs. One is the disc magnet motor. Here the rotor is designed sa a disc with rare earth magnets, see figure 4 .

These qualities are essential in some applications.

How the Stepper motors are made and how they operate (1)

How the Stepper motors are made and how they operate (2)

Reference: Industrial Circuits Application Note – Stepper Motor Basics by PAControl.com

please how can i regulate the speed using programmable logic controller with simatic manager ??

Sir plz share articles about power system

Hi Sir,

The Article you presented was good but please some applications that mean industrial applications for each type individually please