Testing protective conductors

For all protective conductors, including main and supplementary bonding conductors, electricians must perform continuity test using a low-reading ohmmeter. For main equipotential bonding, there is no single fixed value of resistance above which the conductor would be deemed unsuitable.

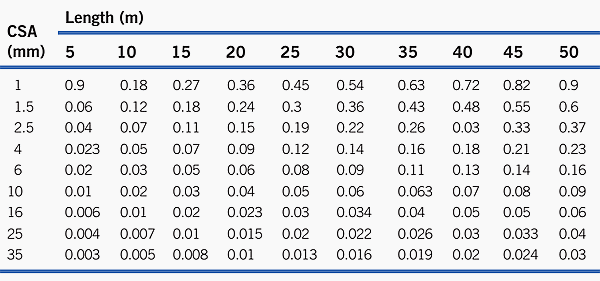

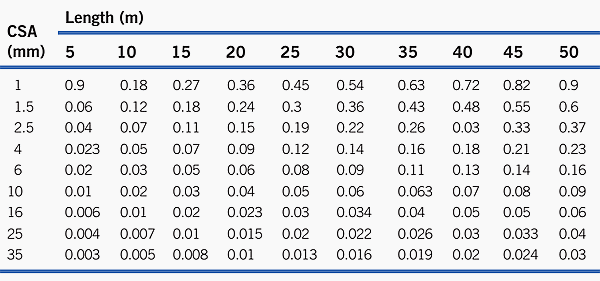

Each measured value, if indeed it is measurable for very short lengths, should be compared with the relevant value for a particular conductor length and size. Such values are shown in Table 1 below.

Table 1 // Resistance ( Ω) of Copper Conductors at 20°C

Where a supplementary protective bonding conductor has been installed between simultaneously accessible exposed and extraneous conductive parts the resistance of the conductor R must be equal to or less than 50/ Ia.

So, R ≤ 50/Ia, where 50 is the voltage, above which exposed metalwork should not rise and Ia is the minimum current, causing operation of the circuit protective device within 5s. For example, suppose a 45 A BS 3036 fuse protects a cooker circuit, the disconnection time for the circuit cannot be met, and so a supplementary bonding conductor has been installed between the cooker case and the adjacent metal sink.

The resistance R of that conductor should not be greater than 50/ Ia, which in this case is 145 A (IEE Regulations). So:

50/145 = 0.34 Ω

How then do we conduct a test to establish continuity of main or supplementary bonding conductors?

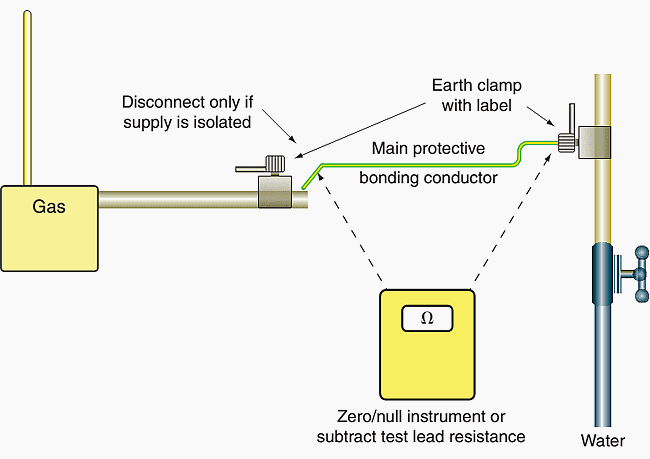

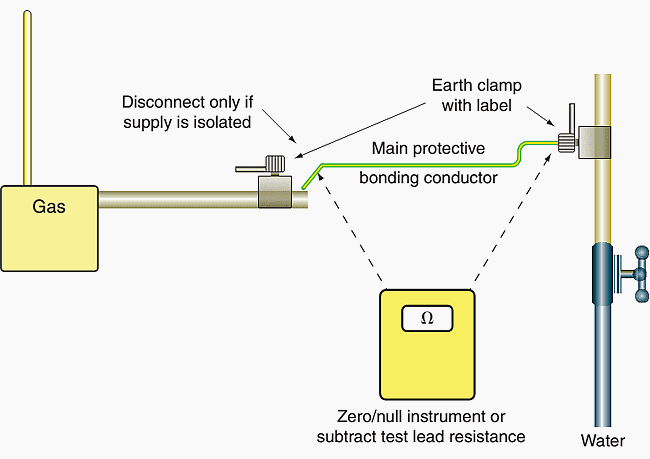

Quite simple really, just connect the leads from the continuity tester to the ends of the bonding conductor (Figure 1). One end should be disconnected from its bonding clamp, otherwise any measurement may include the resistance of parallel paths of other earthed metalwork.

Remember to zero the instrument first or, if this facility is not available, record the resistance of the test leads so that this value can be subtracted from the test reading.

Important Note //

If the installation is in operation, never disconnect main bonding conductors unless the supply can be isolated. Without isolation, persons and livestock are at risk of electric shock.

The continuity of circuit protective conductors (CPC’s) may be established in the same way, but a second method is preferable, as the results of this second test indicate the value of (R1+R2) forthe circuit in question.

The test is conducted in the following way (Figure 2) //

- Temporarily link together the line conductor and CPC of the circuit concerned in the distribution board or consumer unit.

- Test between line and CPC at each outlet in the circuit. A reading indicates continuity.

- Record the test result obtained at the furthest point in the circuit. This value is (R1+R2) for the circuit.

In these cases, continuity tests may have to be carried out at the installation stage before accessories are connected or terminations made off as well as after completion.

Continuity Test of Protective Conductors (VIDEO)

Reference: Electric Wiring: Domestic – Brian Scaddan IEng, MIET

Help!

Dear all

can anyone help me out about equipotential bonding of a turbogenerator?

I surveyed a lot but I did’t find any document or standard that discusses the locations of metallic conductive parts of the generator such as frame, enclosure, cooler, lagging and etc.

Besides, it is not clear how the the CSA of bonding conductors are selected. I’ve read BS 7671 and it related the CSA of bonding conductor to neutral earthing conductor!

Thanks in advance.

I am studying plumbing for the first time. I am doing a section on equipotential bonding, supplementary bonding, cross bonding and temporary continuity bonding. Can you help me to understand these please?

I am VERY concerned about this article.

The whole point of protective bonding is to ensure that any potential difference between contuctive patrts is equalised – hence “equipotential”. There is absolutely no point in installing these essential connectors and then testing between the ends of the wire and not the item that is actually bonded.

Over the years, I have seen many absurd examples of bonding of pipes and structure that – quite simply – the test as you have described would not show…with potentially (no pun intended) catastrophic effect.

– I have seen bonds to oil-painted pipes without the pipe being cleaned to metal – no continuity of bond.

– I have seen a bond on armoured cable being made to the rubber sheath of that cable (!).

– Bonding to powder coated RSJs (again no continuity) etc etc etc.

As a general rule of thumb (and obviously power and voltage dependant) I always recommend to my mentees that – for up to 100A domestic or 100A three phase, they should aim for a maximum resistance of bonding of 0.05 Ohms +/- 0.05 Ohms….(which gives them a maximum variance of 0.1 Ohms).

I always advise not to accept a reading higher…and more importantly …to test the bonded item and NOT the bonding clip!

Mr. Csanyi

In reading your article I am puzzled as to the value of this exercise. In an AC system I see very little value in the operation of overcurrent devices related to open wiring to provide bonding. Ina fault AC current follows the source conductor and any route for bonding wires that is not in intimate influence of the supply conductor will not carry any significant current except in DC systems. the impedance of supplementary bonding is very high for AC systems except where the additional bond wire is run with the supply conductors.

Some very interesting experiments in the 1950s very clearly demonstrates how little current will flow in a bond wire run remotely even in the case where the supplementary bond wire is lower resistance. In one case a 4/0 wire was rune external to a rigid steel raceway and the two return paths had a fault imposed. the external bond wire (lower resistance than the steel raceway)only carried as much as %10 of the current where the steel raceway carried %90. When they moved the wire to the inside of the raceway the added bond wire carried nearly %50 demonstrating the high impedance. In the Canadian Electrical code bonding wires for fault mitigation must be inside of the metal armoured cable or raceway.