Permissible horsepower loading

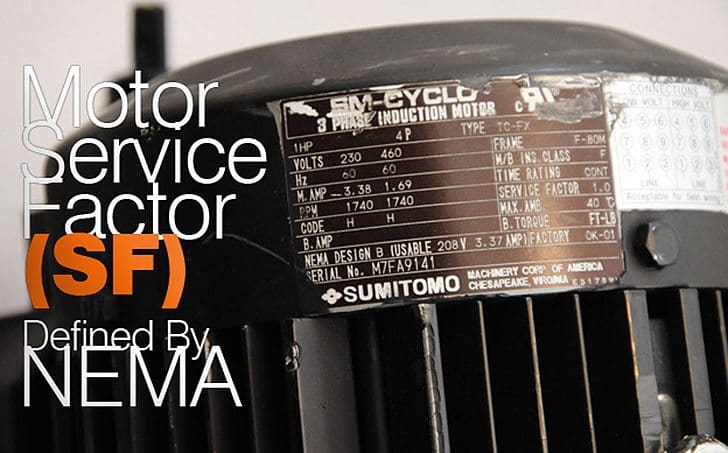

Motor Service Factor (SF) is the percentage of overloading the motor can handle for short periods when operating normally within the correct voltage tolerances.

This is practical as it gives you some ‘fudge’ in estimating horsepower needs and actual running horsepower requirements. It also allows for cooler winding temperatures at rated load, protects against intermittent heat rises, and helps to offset low or unbalanced line voltages.

For example, the standard SF for open drip-proof (ODP) motors is 1.15. This means that a 10-hp motor with a 1.15 SF could provide 11.5 hp when required for short-term use. Some fractional horsepower motors have higher service factors, such as 1.25, 1.35, and even 1.50.

This service factor can be used for the following:

- To accommodate inaccuracy in predicting intermittent system horsepower needs.

- To lengthen insulation life by lowering the winding temperature at rated load.

- To handle intermittent or occasional overloads.

- To allow occasionally for ambient above 40°C.

- To compensate for low or unbalanced supply voltages.

NEMA does add some cautions, however, when discussing the service factor:

- Operation at service factor load for extended periods will usually reduce the motor speed, life and efficiency.

- Motors may not provide adequate starting and pull-out torques, and incorrect starter/overload sizing is possible. This in turn affects the overall life span of the motor.

- Do not rely on the service factor capability to carry the load on a continuous basis.

- The service factor was established for operation at rated voltage, frequency, ambient and sea level conditions.

Most motors have a duty factor of 1.15 for open motors and 1.0 for totally closed motors.

Traditionally, totally enclosed fan cooled (TEFC) motors had an SF of 1.0, but most manufacturers now offer TEFC motors with service factors of 1.15, the same as on ODP motors. Most hazardous location motors are made with an SF of 1.0, but some specialized units are available for Class I applications with a service factor of 1.15.

The service factor is required to appear on the nameplate only if it is higher than 1.0.

Reference: Understanding Motor Nameplate Information: NEMA vs. IEC Standards – Continuing Education and Development, Inc.

You can get most any boat lift motor you need at boatliftwarehouse.com, and you can call and talk to real people for advice.

Dear Engr. Edvard,

We have air compressor motor rated 50hp(37kW), 208-230V rated at 131 – 118 Amperes, 60 Hz, with SF of 142 amps. Motor is TEFC and inverter duty. We had motor winding burn-out issues. The operation is load unload controlled via VFD to maintain pressures from 6.9 bars to 7.6 bars. The voltage of motor ranges from 134-175V, current draws 90-134 amperes, speed/freq. 1100-1335 rpm (39-45hz), it will have a cycle time of approx. 2 minutes from load to unload and repeat again. Is this acceptable motor parameters since our supplier of the compressor claimed that the motor operation is designed as to the SF limits. I am confused with the term occasional or like how frequent is occasional for the motor to have overload conditions.

Hoping for your response. thank you.

Kelso

Hi Sirs

I will appreciate if you can inform whether there will be any weigth difference for a 3500 kW , 6,6 kV motor with service factor 1.0 compared to same motor power but with service factor 1.15.

Thanks

Dear Edvard,Hi

could you please tell me what is Maximum SF for DC motors rated power 200 kw?

Edward, I have two 1-HP boat lift motors that were submerged for 24 hours during a flood here in the Texas Hill Country, west of Austin. They may have been bought as a unit complete with pulleys, belts, etc.

I want to replace just the motor. Type C, 1725 RPM, 115/230, Code L, SF of 1.0, A = 12.2/6.1, (1420 TEB), HSG TENV.

So much information that I don’t know which motor to buy. The tag shows that it was bought from Aqua Marine Supply (heftyhoist.com). Any suggestions on where I need to go and what to specify?

Dear Edvard

when we have mechanical power eg 500 hp and want to heavy duty with 1.5 service factor this mean we should select 750 hp motor? and by 95% efficiency reached to 773 hp electrically is it correct.

if this is correct then motor normally operate on 500 hp (mech) which is lower than 750 hp and is not good.

or the manufacturer gives us 500 hp mechanical power output motor can work temporarily in 750 hp.

thanks for your recommendation.

Dear Edvard,Hi

I dint have NEMA with me,but is there a chance to knowwhat would be teh short time that we can rung the motor according to the SF.

As far as I know if the SF=1.1 for example and the operation duty S1 we can run the motor on Full Load Current for long time( indefinitly) but we cannot run teh same motor on 110% for long time( indfinitly) am I correct?

Please advise and thanking you rcooperation.

Reagrds,

Adnan