Introduction

The source for a PLC power supply is generally single-phase and 120 or 240 VAC. If the controller is installed in an enclosure, the two power leads (L1 hot and L2 common) normally enter the enclosure through the top part of the cabinet to minimize interference with other control lines.

Power requirements

a. Common AC source

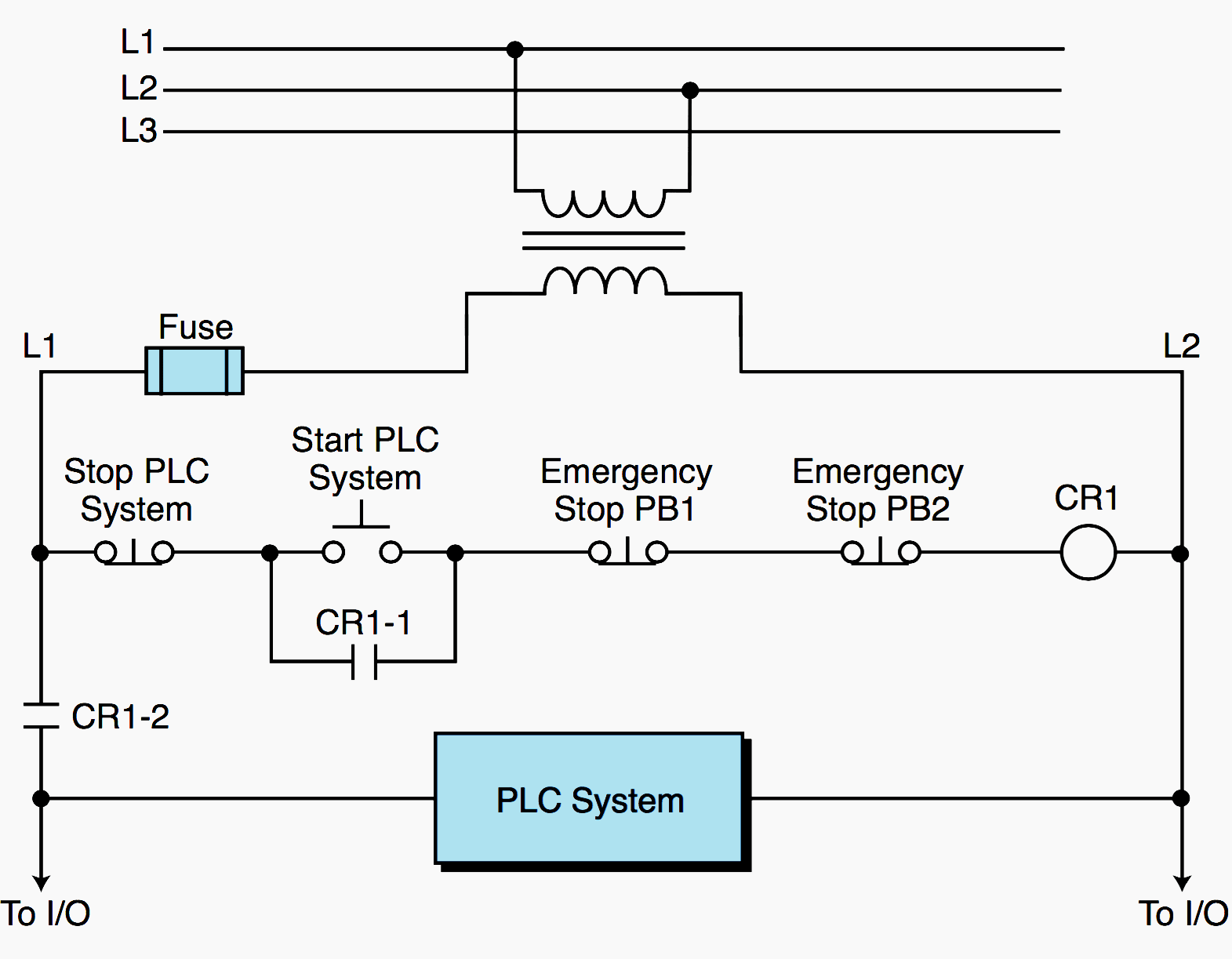

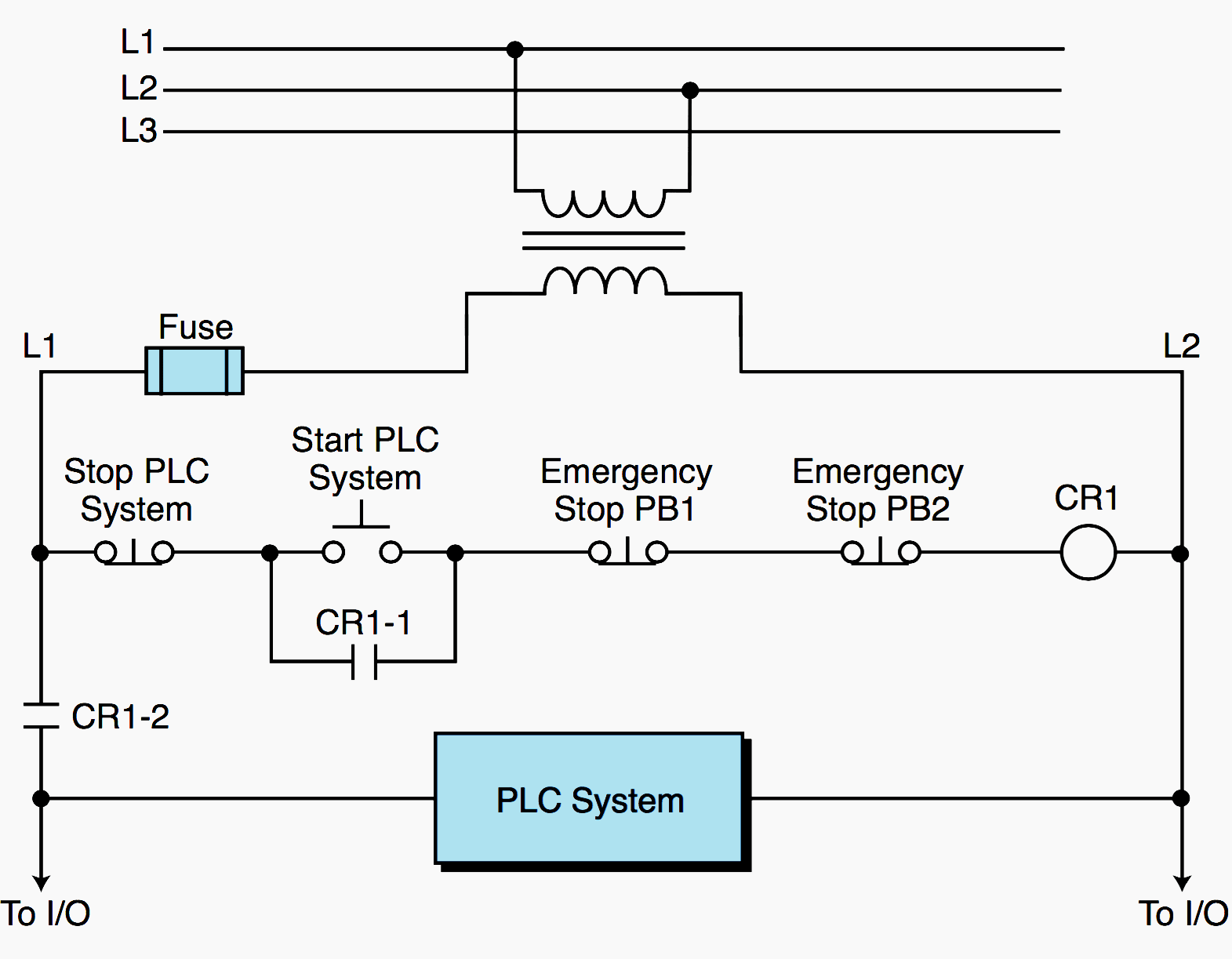

The system power supply and I/O devices should have a common AC source (see Figure 1). This minimizes line interference and prevents faulty input signals stemming from a stable AC source to the power supply and CPU, but an unstable AC source to the I/O devices.

By keeping both the power supply and the I/O devices on the same power source, the user can take full advantage of the power supply’s line monitoring feature.

If line conditions fall below the minimum operating level, the power supply will detect the abnormal condition and signal the processor, which will stop reading input data and turn off all outputs.

Go back to PLC power/safety circuit requirements ↑

b. Isolation transformers

Another good practice is to use an isolation transformer on the AC power line going to the controller.

The transformer should have a sufficient power rating (in units of volt- amperes) to supply the load, so users should consult the manufacturer to obtain the recommended transformer rating for their particular application.

Go back to PLC power/safety circuit requirements ↑

Safety (emergency) circuits

The PLC system should contain a sufficient number of emergency circuits to either partially or totally stop the operation of the controller or the controlled machine or process (see Figure 2).

These emergency circuits should use simple logic with a minimum number of highly reliable, preferably electromechanical, components.

Go back to PLC power/safety circuit requirements ↑

a. Emergency stops

The system should have emergency stop circuits for every machine directly controlled by the PLC. To provide maximum safety, these circuits should not be wired to the controller, but instead should be left hardwired.

These emergency switches should be placed in locations that the operator can easily access.

Emergency stop switches are usually wired into master control relay or safety control relay circuits, which remove power from the I/O system in an emergency.

Go back to PLC power/safety circuit requirements ↑

b. Master or Safety control relays

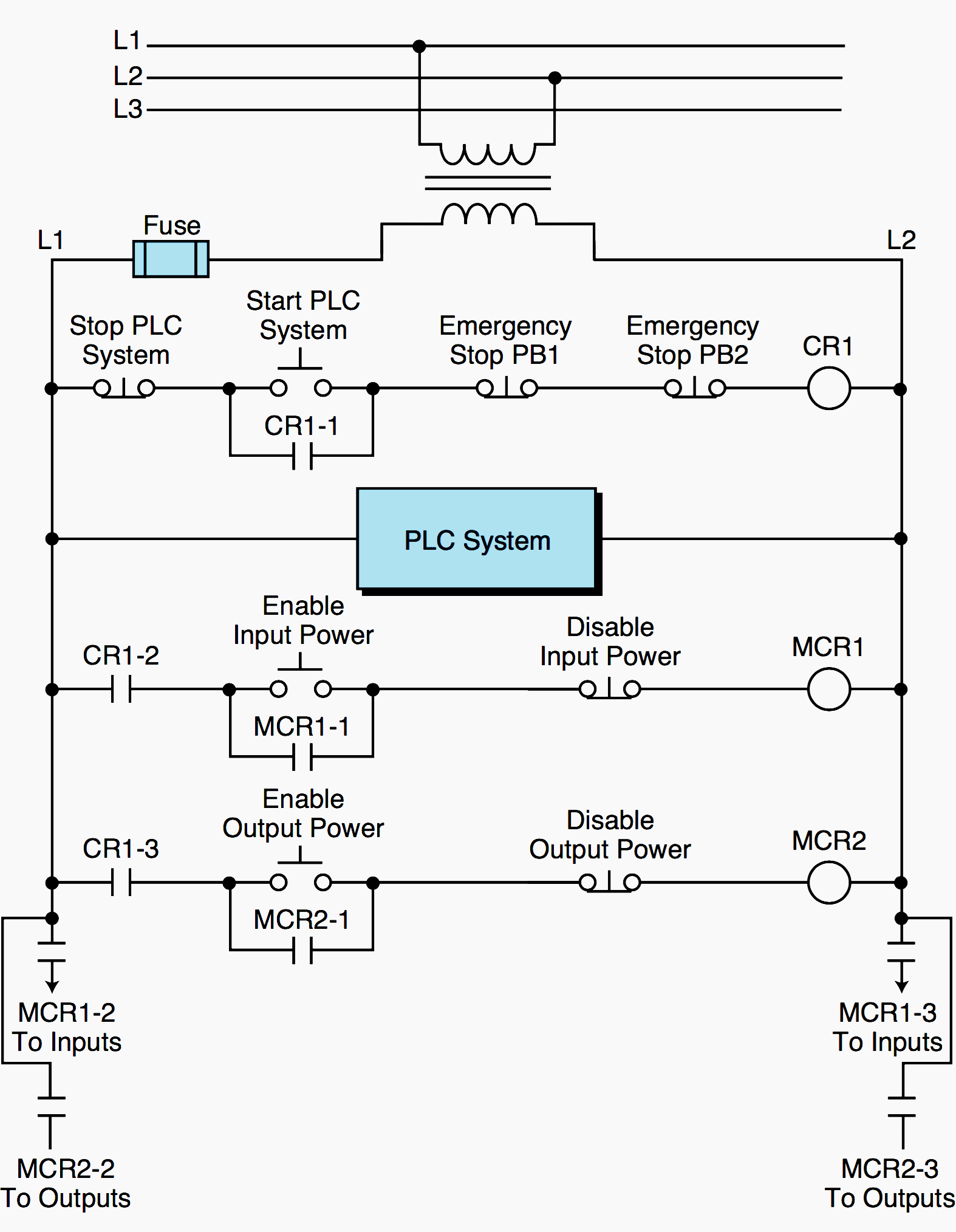

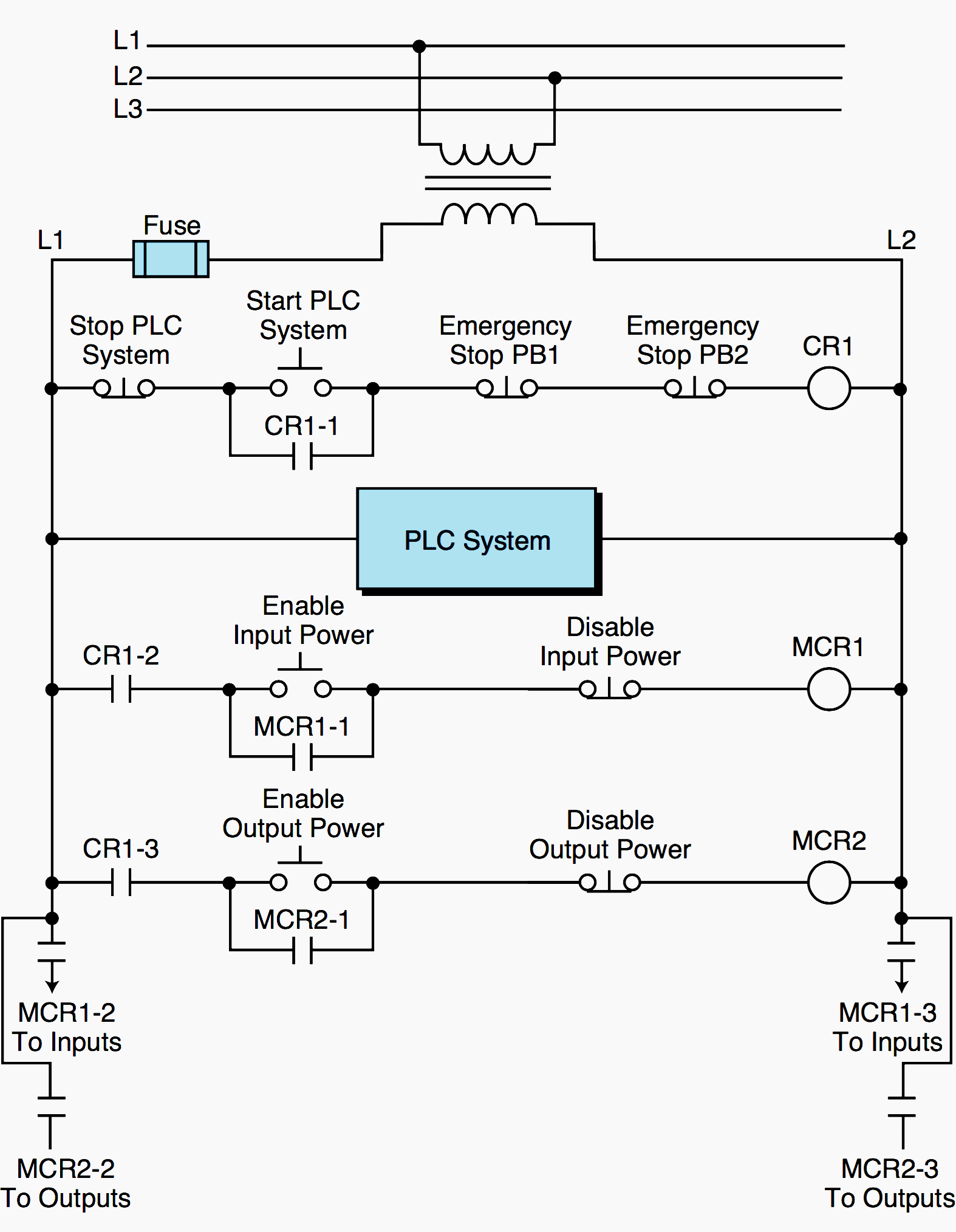

Master control relay (MCR) and safety control relay (SCR) circuits provide an easy way to remove power from the I/O system during an emergency situation (see Figure 8).

These control relay circuits can be de-energized by pushing any emergency stop switch connected to the circuit. De-energizing the control relay coil removes power to the input and output devices. The CPU, however, continues to receive power and operate even though all of its inputs and outputs are disabled.

This enhancement will cause the MCR circuit to cut the I/O power in the case of a PLC failure (memory error, I/O communications error, etc.). Figure 4 illustrates the typical wiring of a master control relay circuit.

Go back to PLC power/safety circuit requirements ↑

c. Emergency power disconnect

The power circuit feeding the power supply should use a properly rated emergency power disconnect, thus providing a way to remove power from the entire programmable controller system (refer to Figure 4). Sometimes, a capacitor (0.47 μF for 120 VAC, 0.22 μF for 220 VAC) is placed across the disconnect to protect against an outrush condition.

Outrush occurs when the power disconnect turns off the output triacs, causing the energy stored in the inductive loads to seek the nearest path to ground, which is often through the triacs.

Go back to PLC power/safety circuit requirements ↑

Reference // PLC Start Up and Maintenance by Industrial Text & Video Company

We would like to know which norm ISO/EN you have adopted your design/structure.

una exelente informacion y muy buena es muy provechoso tener este tipo de informacion diario reviso los que me mandas de sub estaciones y me gustan bastante pero este es diferente el tema es diferente y es lo que actualmente manejamos dentro de una planta industrial saludos

I ran a few large MOC sites over a 20 year period and the best know practice that proved 100% reliability with respect to PLC power supplies and protection, included but not limited to the 120 VAC power supply, conditioned power, I.e. UPS circuit through an isolation transformer, to add on the maintenance check list, ” Don’t forget the change the OEM battery in the PLC. It’s usually a combination of low voltage dc batteries that normally last 10 or more years. There easy to forget unless you have a consistent professional electrical engineering service or service provider through the duration of your equipment life, you will find that creating a client reminder externally and internally with the client for scheduled backups of the programming itself in addition to the battery maintenance.

Can you put editorial for comissioning of PLC and SCADA for substation design

I am avid reader of your editorial..

Sir could you sent me a link for comissioning of PLC and SCADA in substation ..

Thanks a lot

Thanks a lot sir for ur effort in providing resources which is add on technical update …

I am avid reader of your editorial..

Sir could you sent me a link for comissioning of PLC and SCADA in substation ..

Great job. Indeed, most PLCs that I know of do run on 24 DC voltage, and you have dwelt on key emergency(safety) components, also there should be need to include the Rectifier whose function is vital and could constitute a single point of failure. This is in terms of overall reliability of the power supply to the PLC. Thanks

It’s really helpful and informative site for electronics.

Thanks for all the information you part with the world.

Sir am looking for job in Plc and scada

can you explain about PLC and field device (sensor IP) Earthing system?