Bus duct is used for the effective and efficient supply of electricity in mostly industrial locations. Copper or aluminum is used for the conductor of bus duct that be insulated and enclosed completely for protection against mechanical damage and dust accumulation. A bus duct system is an effective method of distributing power to your switchgear and various loads. However, bus duct problems can lead to catastrophic damage and extensive downtime.

Bus duct is used for the effective and efficient supply of electricity in mostly industrial locations. Copper or aluminum is used for the conductor of bus duct that be insulated and enclosed completely for protection against mechanical damage and dust accumulation. A bus duct system is an effective method of distributing power to your switchgear and various loads. However, bus duct problems can lead to catastrophic damage and extensive downtime.

There are basically three general categories of bus duct (all-metal enclosed). The nonsegregated phase bus implies a duct where all phase conductors are in a common metal enclosure without barriers between phases. This definition applies to rigid and flexible conductors such as the bar or cable duct.

Segregated phase bus is a duct where phase conductors are in a common metal enclosure but are segregated by ground metal barriers between each phase conductor. Isolated phase duct is when each phase conductor is enclosed in its own metal housing and adjacent conductor housings are separated by an air space. This duct usually has higher amp ratings than other types. The housing and conductors are tubular in shape and are welded at site together. This duct is force-air cooled above a 25000A continuous rating.

Applicable standards

ANSI C37.23 standard covers the design, manufacture, testing and ratings of the allmetal enclosed bus duct, including cable duct systems. When part of the equipment, it contains the associated equipment such as inter connections, enclosures, switches, supporting structures and disconnecting links. This includes disconnects primarily used with isolated phase duct but can be used with all other types of duct, including cable duct.

Outside the scope of this standard is duct rated to 600V or open type conductor assemblies. The CSA C22.2 No. 201 standard is the Canadian measure for metalenclosed duct for voltages rated from 751V to 46kV, AC or DC. This standard covers the design, manufacture, testing and ratings of all types of metal-enclosed bus duct including cable duct systems. It includes all accessories associated with all types of duct, as does ANSU. For isolated phase duct, it is limited to amp ratings up to 5000A continuous.

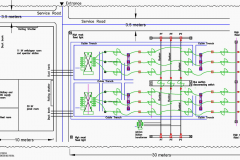

Application

All three duct systems are actually identical as to application and have the same basic ratings as previously listed. Price usually determines which application is most appropriate for which type of duct. One should not consider the duct cost alone but include the cost of installation, and therefore the total cost of the installed duct system.

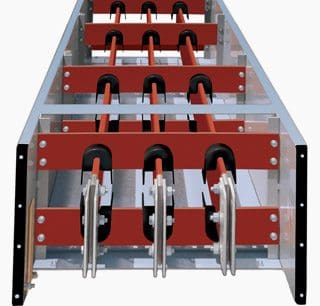

In general, segregated bus duct can be considered slightly more reliable than non-segregated duct based on the fact that a-bus-to-ground fault may be contained within the separate, groundedmetal- barriered compartments. This is particularly true for initially low-level ground faults that exist on an ungrounded, or high-resistance grounded, system. Rigid conductor bus duct is basically factory manufactured and requires bolting sections together in the field and installing insulated conductor joint boots.

Accessories are generally factory assembled, including equipment such as switchgear and transformers. On the other hand, cable duct is normally supplied to the installing contractor on nonreturnable reels for field installation and termination.

Standard switchgear or transformer connections are direct via the cable with suitable stress kits or terminating kits, depending on the termination requirement. Special terminating boxes with rigid copper conductor connections can be supplied to the cable from which the duct is connected. With rigid duct, tee arrangements are quite practical.

It can also be accomplished with cable duct but with much more difficulty. The tee arrangement is manufactured of rigid conductors in an enclosure in which the cable duct system is connected to all sides. This requires stress cone kits or cable terminating kits at each cable termination. Such an arrangement requires considerable space and is costly.

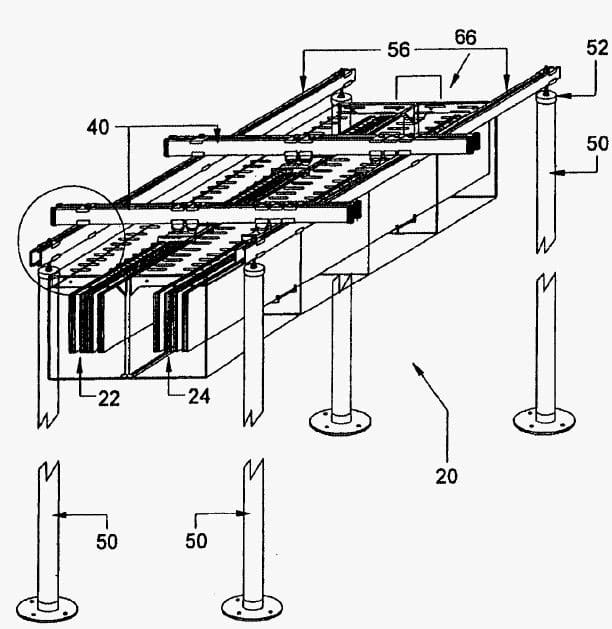

Hanger supports, wall supports and freestanding floor supports are basically similar for all types of duct. Isolated phase duct, which becomes a requirement for generator feeds due to the normal continuous current rating and minimum BIL level of 110kV, is manufactured from aluminum tube type housings and conductors. The conductors are supported on porcelain, post-type insulators, and the duct system is pre-manufactured in specified lengths depending on the duct system’s physical arrangement. The installing contractor welds the conductors and housing in the field.

Isolated phase ducts are used for high ampacity requirements and can be supplied up to 25000A continuous rating without forced-air cooling. Beyond this rating, forced-air cooling is required with all the associated equipment. All accessories such as elbows, tees, the isolating switch and termination to the equipment it feeds are specifically designed for the application and generally come factory assembled, except for termination.

Isolated phase duct is quite special compared to the other duct systems described and requires considerably more space. It is also significantly more expensive to purchase and install, but deemed a unique system for specific applications and, in particular, as a generator duct feed. In general, rigid conductor type bus duct length is measured from centre line to centre line, and the equipment to which it is attached, to establish overall duct-length footage. Bar extensions within a termination cubicle are considered part of the termination equipment. For cable duct, the same criteria is used to establish length.

The only exception is that 60 inches of duct length must be added to establish overall length dimensions, due to the cable extension leads required at each end. Such cable lead extensions are considered part of the duct length, rather than part of the termination equipment.

Ratings

Non-segregated duct, which includes cable duct, basically has the same continuous current ratings, from 600A to 6000A. Duct of higher ratings is supplied up to 12000A, but this is for special applications requiring special design, manufacturing and installation considerations. Ampacities are normally based on 40°C ambient where conductors have silver-plated joints, and the allowable temperature rise of the conductor is 65°C. Noncurrent carrying parts that can be readily touched are allowed a 40°C rise. Ambient temperature range limits are -30°C to +40°C, and altitude is up to 1000 metres (3300 feet). Other ambient conditions need special consideration and may contribute to derating.

Voltage range for these types of duct are basically from above 600V to 34.5kV to ANSI but to 46kV to CSA. In practical terms, the maximum rating is 38kV with a BIL rating of 150kV. This includes cable duct, even though cable at nominally 38kV can have a higher BIL rating and can certainly have a higher insulating voltage class such as up to 33 per cent insulation on higher voltage ratings. To ANSI standards, corona extinction levels are not specified, but they are to CSA standards and are considered a production type test.

Momentary ratings are not specified in the standards but the duct is expected to be suitable and match the momentary rating of the equipment to which it is connected. In general terms, the momentary ratings offered are 82 kA, 100kA or 150kA for 600V ratings; 60kA, 80kA and 100kA for five and 15kV ratings; 6kA and 80kA for 25 and 38kV ratings. The DC bus duct nominal voltage rating is 300 to 3200 volt DC with continuous ratings up to 6000A. Isolated phase duct continuous ratings go from 1200 to 24000A (self-cooled) although tests have been conducted to 25000A for self-cooled current ratings.

Voltage ratings are 24.5, 29.5 and 34.5kV with corresponding BIL ratings of 110, 125 and 150kV for direct generator connections. Other than generator connection, voltage levels are 15.5, 25.8 and 38kV with corresponding BIL ratings of 110, 125, and 150kV.

Sir i required details of bus duct system Lv for 6000amp 440 v ac … Use of material . Type of both end joint. How to reduce temperature.how to reduce humming and noise .. bus phase to phase distance . BOQ . installation outer enclosure material .. cooling system ..and designing

Can you help me with 4000 amps air insulated busduct specifications for 45 degrees ambient

I need specifications for 4000amps air insulated busduct

Dear Sir,

I am an author of electrical textbook for Delmar Publishers in Albany, NY. I am in the process of revising a textbook titled, “Electrical Wiring Industrial”. In this revision the book is being changed from single color to full color. I am trying to find replacement photos for the existing black and white photos. I saw a color photo of a bus duct on your wedsite and would like to have a copy of that photo for publication if possible. If you can supply that photo I will have the publisher contact you for the proper permission for publication. Thank you for your time and consideration.

Stephen L. Herman

Hi sir,

How to design a CSA or UL891, 600V, 1200A, 30kAIC bus bar with support.

From your point of view a breaker 1200A MCB is better to install in vertical or horizontal position.

Regard

SIR,

HOW TO DESIGN A 11KV/440V 3PHASE SUBSTATION 500 KVA X2 TRANSFORMERS

PL GIVE CIRCUIT DIAGRAM AND ALL DETAILS

THANKS