History of Relay

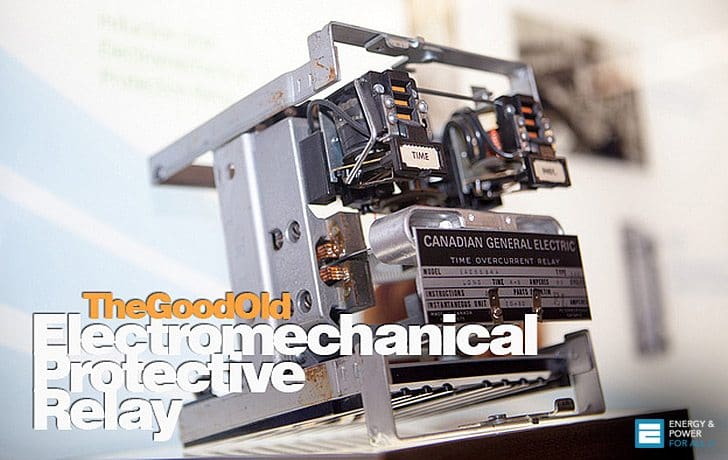

This is the first generation oldest relaying system and they have been in use for many years. They have earned a well-deserved reputation for accuracy, dependability, and reliability.

There are two basic types of operating mechanisms:

- Electromagnetic-attraction relay and

- Electromagnetic-induction relay

Measuring Principles

The electromechanical protective relay converts the voltages and currents to magnetic and electric forces and torques that press against spring tensions in the relay.

The tension of the spring and taps on the electromagnetic coils in the relay are the main processes by which a user sets in a relay.

Function of Relay

These relays are usually instantaneous in action, with no intentional time delay, closing as soon after pickup as the mechanical motion permits. We can add time delay by means of a bellows, dashpot, or a clockwork escapement mechanism.

However, the timing accuracy is considerably less precise than that of induction type relays.

As such, users seldom choose these relays with time delay in switchgear applications.

Most relays come enclosed in a semi flush-mounting draw out case. Installers typically install relays usually on the door of the switchgear cubicle. They bring sensor and control wiring to connections on the case. The relay inserts into the case and connects by means of small switches or a bridging plug, depending on the manufacturer.

As such, we can disconnect and withdraw it from the case without disturbing the wiring. When the relay is disconnected, the current transformer (CT) connections in the case are automatically shorted to short circuit the CT secondary winding and protect the CT from over voltage and damage.

Operation of Electromagnetic-attraction Relay

Figure shows a typical electromechanical relay. An input voltage is applied to the coil mechanism. The input voltage magnetizes the core which pulls the arm towards it. This action causes the output contacts to touch, closing the load circuit.

When the input voltage is removed, the spring lever will push the contacts away from each other, breaking the load circuit connection.

Operation of Electromagnetic-Induction Relay

Induction relays are available in many variations to provide accurate pickup and time-current responses for a wide range of simple or complex system.

Until the rotational forces are great enough to turn the disk and bring its moving contact against the stationary contact, a spring restrains the disk motion.

This closes the circuit the relay is controlling. The greater the sensed fault, the greater the current in the coils, and the faster the disk rotates.

A calibrated adjustment called the time dial sets the spacing between the moving and stationary contacts; this varies the operating time of the relay from fast (contacts only slightly open) to slow (contacts nearly a full disk revolution apart).

Reset action begins upon removing the rotational force, either by closing the relay contact that trips a breaker or by otherwise removing the malfunction the relay is sensing. The restraining spring resets the disk to its original position. The time required to reset depends on the type of relay and the time-dial setting (contact spacing).

Most electromechanical Relays are typically rated for minimum input to output isolation voltages of 1500 to 2000 VAC.

Limitations of Electromagnetic relays

- Low speed of operation.

- Change in characteristics over a period due to ageing effect.

- Component failure leading to relay failure.

- Relay is Bulky: Because there are internal mechanical components with physical dimension restraints, the package size of an electromechanical Relay can limit the size of a PCB design Excessive power consumption.

- Imposes high burden on CT

- No fault data available except phase indication.

- Inherent in its design, the Electromechanical Relay must make mechanical contacts in order to switch a load. At the point of these contacts, oxidation breakdown occurs over extended life cycling (typically 106 operations), and the relay will need to be replaced.

- When an electromechanical Relay is activated, bounce occurs at the contact site. Bounce creates a window of time where the load circuit is flickering between open and closed, a condition which may need to be considered in load design.

- Isolation voltage is another area where Electromechanical Relays are limited.

References

- Handbook of Switchgear –Bhel

- Digital/Numerical Relays -T.S.M. Rao

I have an electric Spincraft electric boat that won’t stay running. We deduced that it is a faulty electromechanical relay. The number on the relay is 12VDC 42/30A Tyco VF4-45F11.

Is there anywhere in Ottawa, Ontario, Canada where I can get one of these?

If there is not a dealer, then how can I get one, please? I have also called a few marine dealers but they could not help.

There used to be a Spincraft dealer in Ottawa, but when I call the number listed on the net, it says it is out of service.

Thank you for any help you can give me.

Margaret

That relay, Tyco VF4-45F11, is available from a number of places. Try Digikey.ca or Mouser.ca.

https://www.digikey.ca/product-detail/en/te-connectivity-potter-brumfield-relays/VF4-45F11/PB527-ND/420427

still have the spincraft?

How to cpntrol the speed or the operating time of induction relay ?

I found a great online resource to browse and compare similar products: http://www.directindustry.com/industrial-manufacturer/relay-64634.html

I would have to question the need to replace a relay after 106 operations. I have calibrated relays that were 50 years old (in the 1980’s) that still maintained their calibration of +/- 5% of pu and +/-5% timepoint.

Proper maintenance of these relays will keep them in-service for many years of useful operation. The micorprocessor based relays of today have a distinct advantage over the electromechanical relays as they require far less maintenance (usually only operational tests) and multiple relays can be placed in a single 19″ package. The only disadvantage is that you have all your eggs in one basket, if one component fails, you must replace the entire relay.

As far as contact bounce, I have never seen a relay contact that failed to trip its output device on the first shot. The only time that I witnessed a contact bounce that failed to operate the output device is during testing when we we establishing the actual pickup point.

This was due to the extremely low current applied to the relay. During a fault these relays functioned properly.

Hello,

Please what are possible equipment that can be put to use in the calibration of electromechanical relays.