What is the operating principle of a 3ph induction motor?

An electric motor converts electrical energy into a mechanical energy which is then supplied to different types of loads. A.c. motors operate on an a.c. supply, and they are classified into synchronous, single phase and 3 phase induction, and special purpose motors. Out of all types, 3 phase induction motors are most widely used for industrial applications mainly because they do not require a starting device.

A 3 phase induction motor derives its name from the fact that the rotor current is induced by the magnetic field, instead of electrical connections.

The operating principle of a 3 phase induction motor is based on the production of r.m.f.

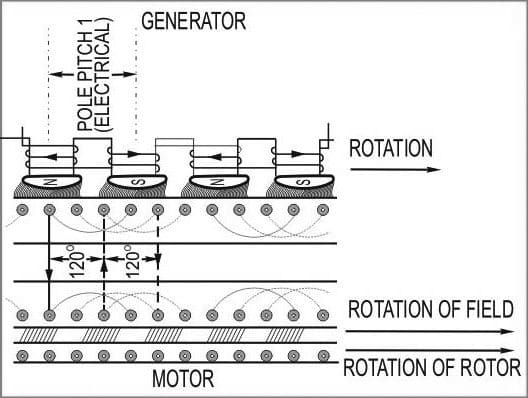

Production of a rotating magnetic field

The stator of an induction motor consists of a number of overlapping windings offset by an electrical angle of 120°. When the primary winding or stator is connected to a three phase alternating current supply, it establishes a rotating magnetic field which rotates at a synchronous speed.

The direction of rotation of the motor depends on the phase sequence of supply lines, and the order in which these lines are connected to the stator. Thus interchanging the connection of any two primary terminals to the supply will reverse the direction of rotation.

The number of poles and the frequency of the applied voltage determine the synchronous speed of rotation in the motor’s stator. Motors are commonly configured to have 2, 4, 6 or 8 poles. The synchronous speed, a term given to the speed at which the field produced by primary currents will rotate, is determined by the following expression.

Synchronous speed of rotation = (120* supply frequency) / Number of poles on the stator

Production of magnetic flux

A rotating magnetic field in the stator is the first part of operation. To produce a torque and thus rotate, the rotors must be carrying some current. In induction motors, this current comes from the rotor conductors. The revolving magnetic field produced in the stator cuts across the conductive bars of the rotor and induces an e.m.f.

The rotor windings in an induction motor are either closed through an external resistance or directly shorted. Therefore, the e.m.f induced in the rotor causes current to flow in a direction opposite to that of the revolving magnetic field in the stator, and leads to a twisting motion or torque in the rotor.

As a consequence, the rotor speed will not reach the synchronous speed of the r.m.f in the stator. If the speeds match, there would be no e.m.f. induced in the rotor, no current would be flowing, and therefore no torque would be generated. The difference between the stator (synchronous speed) and rotor speeds is called the slip.

What results is a motor that is:

- Self-starting

- Explosion proofed (because of the absence of slip rings or commutators and brushes that may cause sparks)

- Robust in construction

- Inexpensive

- Easier to maintain

Thankful for the info I’m getting here…. Keep up the good work

Thanks for your explanation

I need more about Induction motor

Please explain the principle

Of operation of there phase induction motor

I am very thankful to you and the team EEP

Hiii

Need some more detailed info about 3 phase induction motor

I am very thankful to you and the team EEP

We need Three fase induction motor.

I want three phase motors in reasonable prices

I have v6&v4 starters manufacturing factory.

9060550358

We need all types of pannels

Greetings….!

This is my first experience with your website.

Of course you all are doing a great job in simple and comprehensive explanations.

Being MEP Training Manager, I find it very useful.

Regards with thanks.

A nice portal to get knowledge about electricity

i wanna know what will happen if a centrifigul switch does not cut out when a motor have reached its full load speed?

The start winding can burn out

Nice description of induction motor…

Nice portal

I’ll like to know more about 3phase induction motors