Introduction to motor torque

The rotating force that a motor develops is called torque. Due to the physical laws of inertia, where a body at rest tends to remain at rest, the amount of torque necessary to start a load (starting torque) is always much greater than the amount of torque required to maintain rotation of the load after it has achieved normal speed.

The more quickly a load must accelerate from rest to normal rotational speed, the greater must be the torque capability of the motor driver.

The National Electrical Manufacturers Association (NEMA) provides design letters to indicate the torque, slip, and starting characteristics of three-phase induction motors.

They are as follows:

Design A

Design A is a general-purpose design used for industrial motors. This design exhibits normal torques and full-load slip of approximately 3 percent and can be used for many types of industrial loads.

Design B

Design B is another general-purpose design used for industrial motors. This design exhibits normal torques while also having low starting current and a full-load slip of approximately 3 percent. This design also can be used for many types of industrial loads.

Design C

Design C motors are characterized by high starting torque, low starting current, and low slip. Because of its high starting torque, this design is useful for loads that are hard to start, such as reciprocating air compressors without unloader kits.

Design D

Design D motors exhibit very high starting torque, very high slip of 5 to 13 percent, and low starting current. These motors are excellent in applications such as oil field pumping jacks and punch presses with large flywheels.

Variable-torque and Constant-torque motors

Variable-torque motors exhibit a speed-torque character-istic that varies as the square of the speed.

For example, a two-speed 1800/900-rpm motor that develops 10 hp at 1800 rpm produces only 2.5 hp at 900 rpm. Variable-torque motors are often a good match for loads that have a torque requirement that varies as the square of the speed, such as blowers, fans, and centrifugal pumps.

Constant-torque motors can develop the same torque at each speed; thus power output from these motors varies directly with speed. For example, a two-speed motor rated at 10 hp at 1800 rpm would produce 5 hp at 900 rpm.

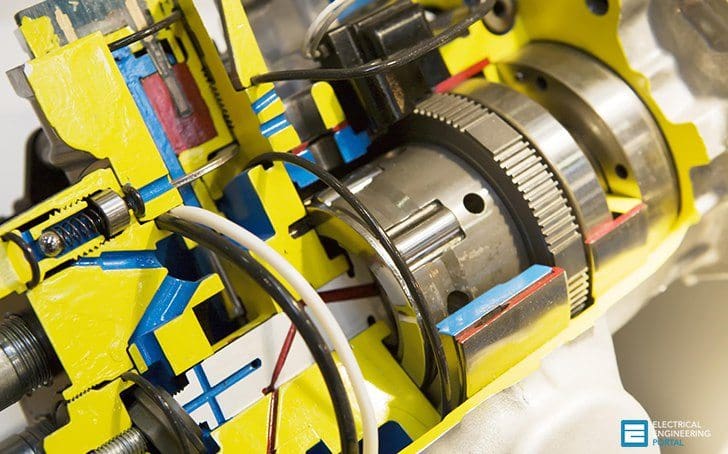

Induction Motor How it works? (VIDEO)

Resource // Electrical Calculation Handbook – John M. Paschal

Greetings, good article.

Variable torque motors would be used to work with a vfd in an extruder ¿?

good information please keep sharing with us.

Thank you Babat!