Motor Duty / Load Cycle

The term duty defines the load cycle to which the machine is subjected, including, if applicable, starting, electric braking, no-load, and rest de-energized periods, and including their durations and sequence in time. Duty considered as a generic term, for example, can be classified as a continuous duty, short-time duty, or periodic duty.

The percentage ratio between the period of loading and the total duration of the duty cycle is defined cyclic duration factor. It is the responsibility of the purchaser to declare the duty.

Where the purchaser does not declare the duty, the manufacturer shall assume that duty type S1 (continuous running duty) applies. The duty type shall be designated by the appropriate abbreviation and the purchaser may describe the type of duty based on the classifications according to the indications given below.

In compliance with the classification of Std. IEC 60034-1 here are some indications regarding the duty types which are typically considered as a reference to indicate the rating of the motor.

- What is the Motor Duty or Load Cycle?

- Continuous running duty (type S1)

- Short-time duty (type S2)

- Periodic duty (type S3-S8)

- Intermittent periodic duty (Type S3)

- Intermittent periodic duty with starting (Type S4)

- Intermittent periodic duty with electric braking (Type S5)

- Continuous-operation periodic duty (Type S6)

- Continuous-operation periodic duty with electric braking (Type S7)

- Continuous-operation periodic duty with related load / speed (Type S8)

- Non-periodic duty (type S9)

- Duty with discrete constant loads (and speeds) – type S10

- Duty for equivalent loading

1. What is the Motor Duty or Load Cycle?

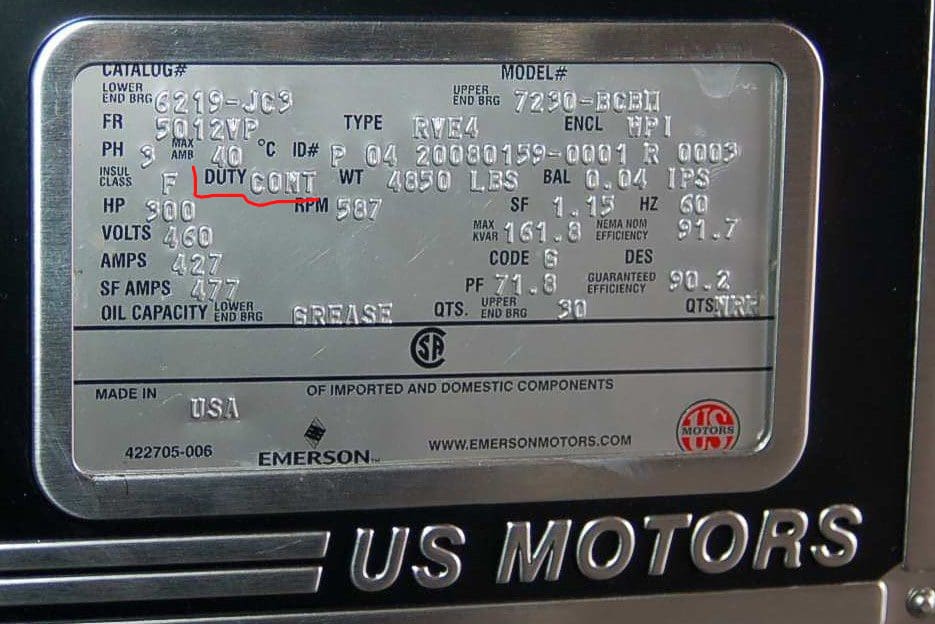

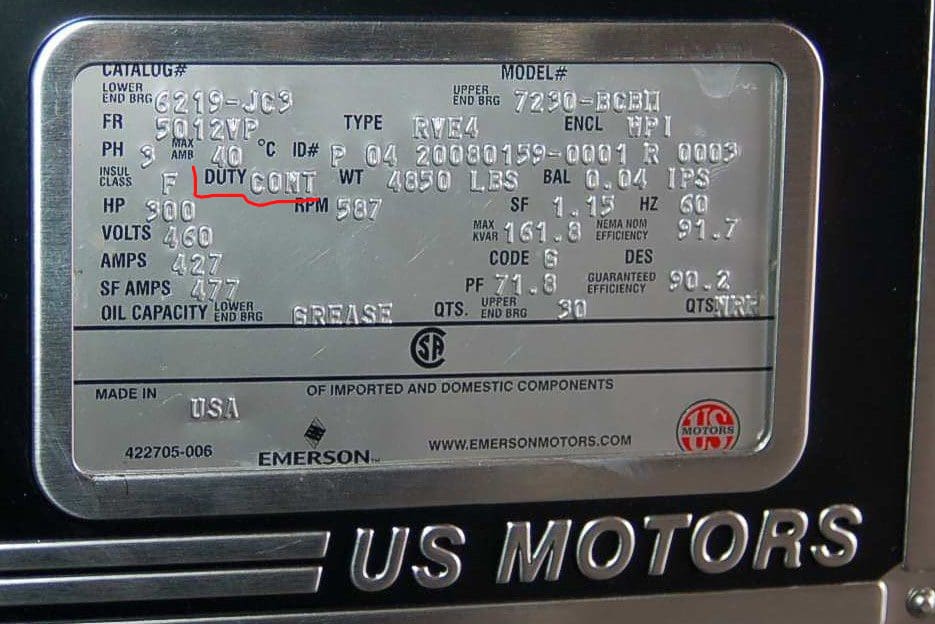

Simply speaking, electric motors are rated according to how much power they can generate without overheating in a specific amount of time. It’s as simple as that! The ratings are indicated on the motor nameplate. The motor duty cycle defines the duration and intensity of loads, intervals of no load, and times of motor inactivity.

Essential information for evaluating motor duty include motor load inertia, required acceleration, anticipated frequency of starts and stops per hour, load magnitude and duration, along with additional factors such as environmental considerations.

A motor with a 50% duty cycle must be idle for an equivalent duration to the period it has been operational. Motors having a duty cycle below 100% possess a maximum operational duration, often limited to 30 minutes. A motor with a 50% duty cycle may operate at its rated output for 30 minutes within a 30-minute operational period.

It must remain off for a minimum of 30 minutes, totaling 60 minutes, before it can be operated again.

Figure 1 – Motor duty information shown on the motor nameplate

When selecting motors based on duty classes, motors in continuous duty applications may operate at or near their rated capacity due to regulated temperature rise, however in intermittent duty applications, motors are restricted by the permissible number of starts and stops per hour.

The duty class is a crucial factor in the selection and installation of an electric motor. Duty class pertains to the duration a motor works within a single cycle. Modern electric motors are utilized for nearly all daily activities. However, the running durations for all motors vary from one another.

Some motors operate for an extended duration, while others have a run time that is less than their rest interval.

2. Continuous running duty (type S1)

For a motor suitable to this duty type, the rating at which the machine may be operated for an unlimited period is specified. This class of rating corresponds to the duty type whose appropriate abbreviation is S1.

Definition: The duty type S1 can be defined as operation at a constant load maintained for sufficient time to allow the machine to reach thermal equilibrium.

Continuous duty refers to a service requirement that necessitates operation at a nearly constant load for an infinite duration. This is the predominant duty classification, including roughly 90% of motor applications. To appropriately fit a motor for a specific application with this duty cycle classification, you should choose the correct horsepower based on continuous load requirements.

Figure 2 – Continuous running duty: Duty type S1

Where: ΔT – Time sufficient to allow the machine to reach thermal equilibrium

3. Short-time duty (type S2)

For a motor suitable to this duty type, the rating at which the machine, starting at ambient temperature, may be operated for a limited period is specified. This class of rating corresponds to the duty type whose appropriate abbreviation is S2.

Definition: The duty type S2 can be defined as operation at constant load for a given time, less than that required to reach thermal equilibrium, followed by a time de-energized and at rest of sufficient duration to re-establish the equilibrium between the machine temperature and that of the coolant temperature.

A complete designation provides the abbreviation of the duty type followed by an indication of the duration of the duty (S2 40 minutes).

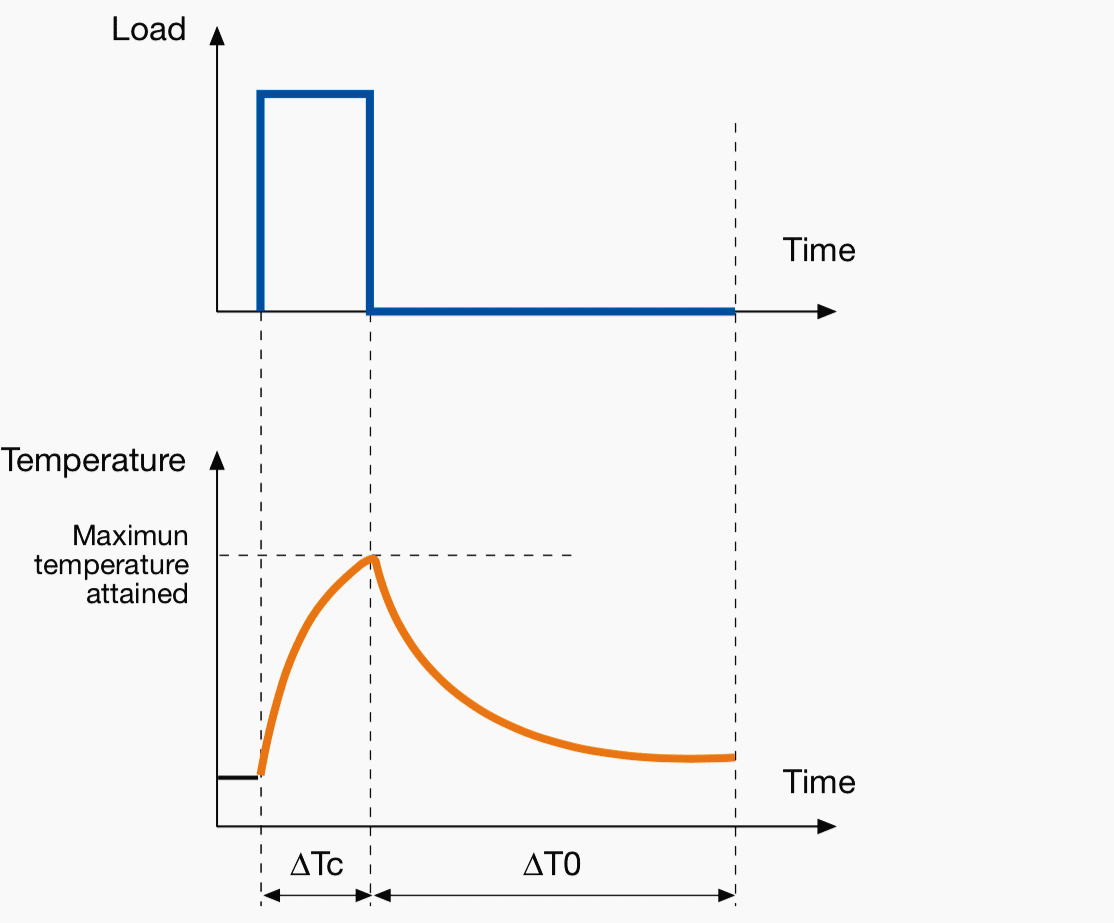

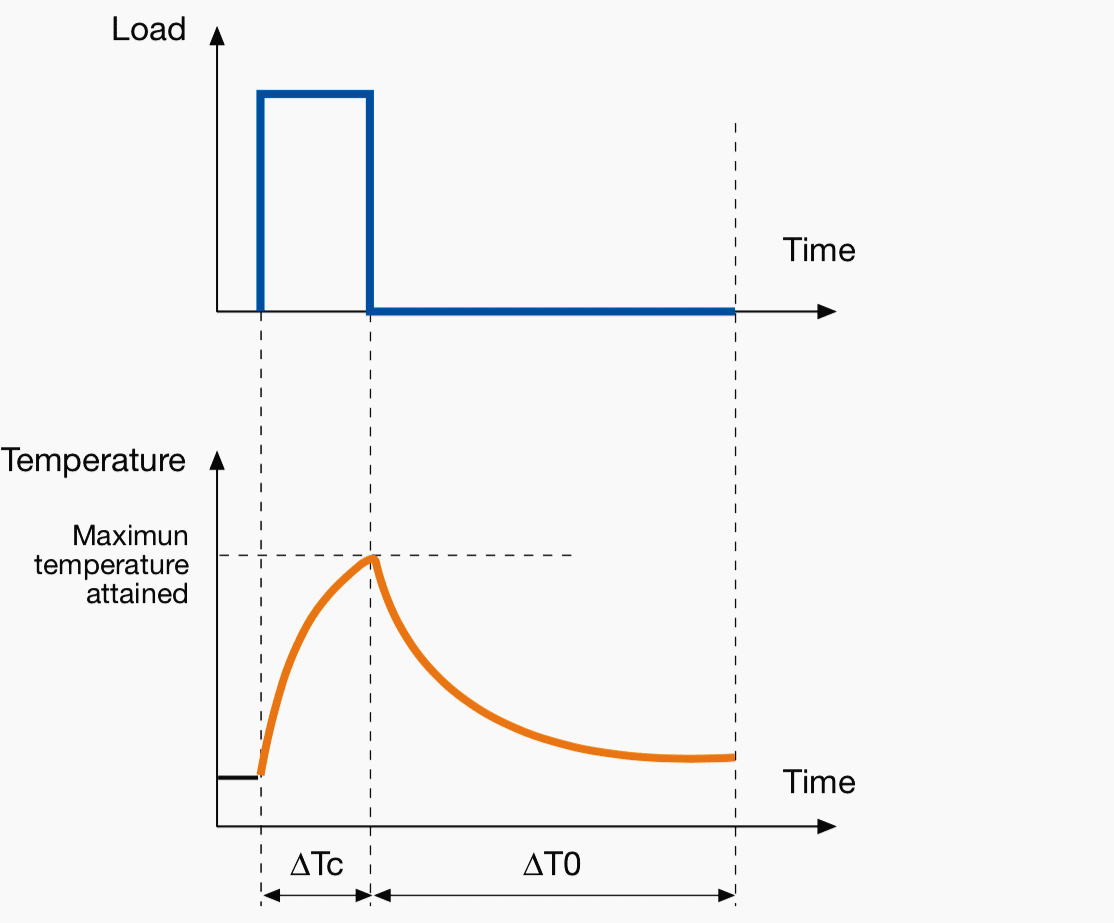

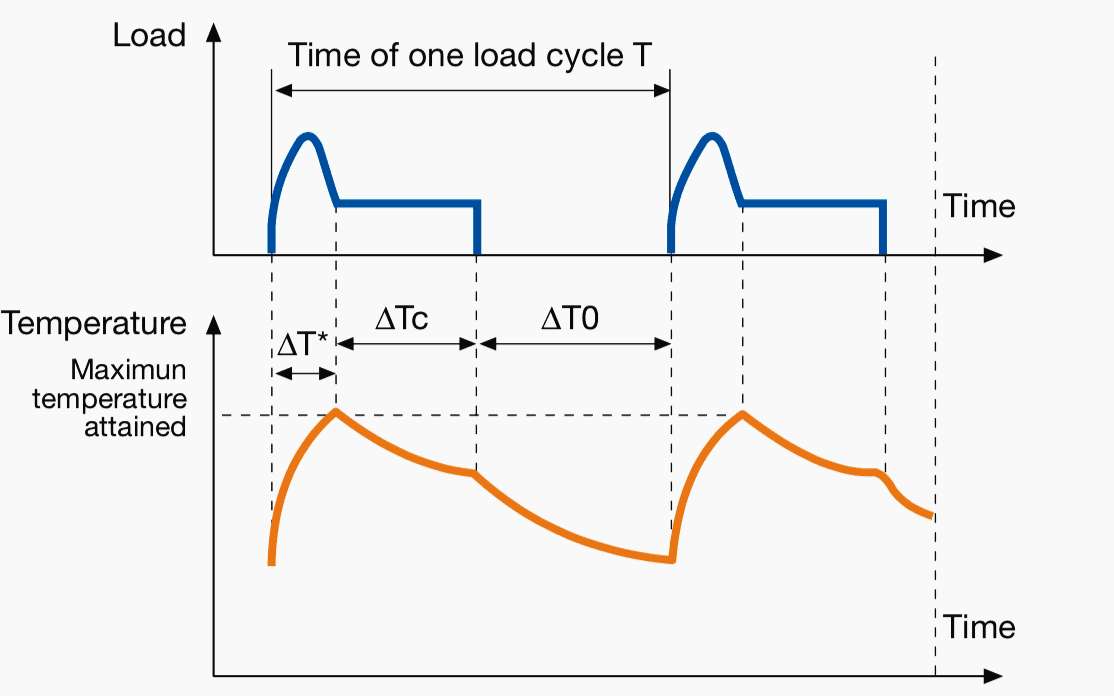

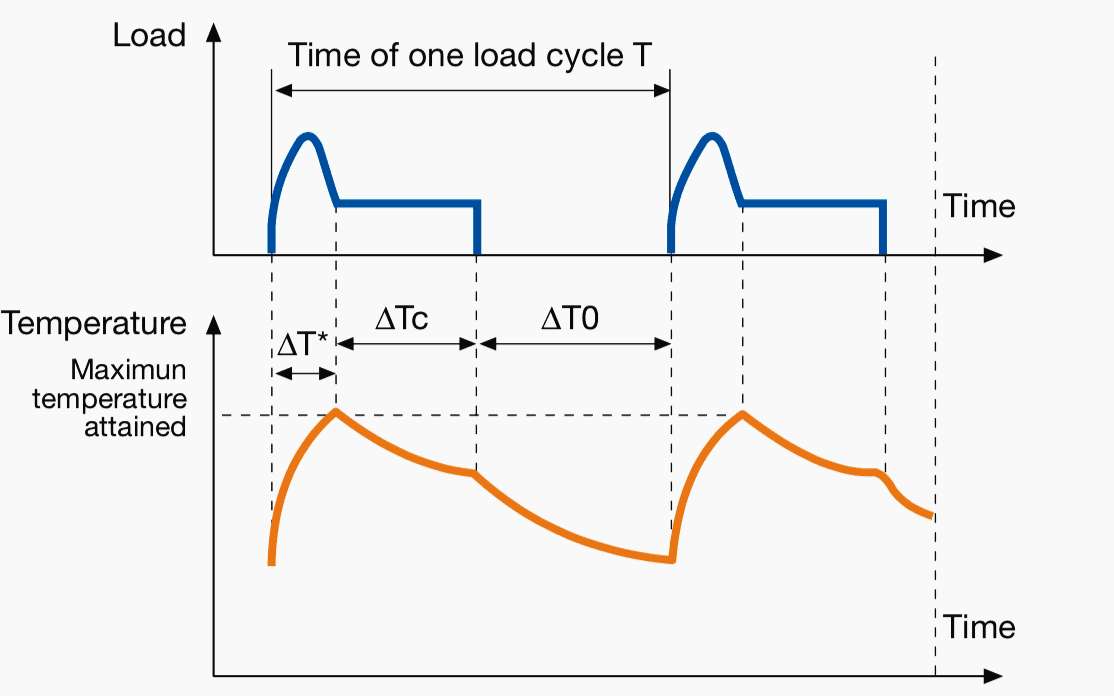

Figure 3 – Short-time duty: Duty type S2

- ΔTc – Operation time at constant load

- ΔT0 – Time de-energized

Applications for Short-time duty motors

Valve drives

Valves are operated by an electrical motor. It provide a torque to operate valves. They are quiet, non-toxic and energy efficient. These motors are specially used for automation of valves as they provide higher torque from standstill than comparable conventional motors.

Hair dryer

There are a motor driven fan and a heating element inside a hair dryer. In a hair dryer there are three switches, one switch for on and off, one switch for air flow controlling and another one for temperature controlling. Hair dryer dries hair by speeding up the evaporation. Hot air is emitted by the hair dryer and that temperature of the air helps for hair drying.

Most hair dryers have high and low airflow settings. You’ll see this referred to in the manual accompanying the hair dryer as high or low speed, because changing the airflow involves modulating the speed at which the

motor is turning.

This is accomplished very simply by altering the current flowing through the part of the circuit feeding the motor. When the power supplied is low, the motor and the fan spin slowly. Less air is pushed through the hair dryer. With more power, the motor speeds up. The fan rotates rapidly, drawing in more air and increasing the airflow.

Egg beater

Egg beater has a rotating handle with a large beveled gear attached at the axis which drives a small beveled gear to much higher rpm. Egg beaters use small motor to get the rotary motion. Electric mixers put smaller bevel gears inside the beater to change the direction and there is a speed selection switch to select the speed.

4. Periodic duty (type S3-S8)

For a motor suitable to this duty type, the rating at which the machine may be operated in a sequence of duty cycles is specified. With this type of duty, the loading cycle does not allow the machine to reach thermal equilibrium.

If no otherwise specified, the duration of a duty cycle shall be 10 minutes and the cyclic duration factor shall have one of the following values: 15%, 25%, 40%, 60%.

The cyclic duration factor is defined as the ratio between the period of loading, including starting and electric braking, and the duration of the duty cycle, expressed as a percentage.

4.1 Duty type S3

Intermittent periodic duty

Definition: The duty type S3 is defined as a sequence of identical duty cycles, each including a time of operation at constant load and a time de-energized and at rest. The contribution to the temperature-rise given by the starting phase is negligible.

A complete designation provides the abbreviation of the duty type followed by the indication of the cyclic duration factor (S3 30%).

Figure 4 – Intermittent periodic duty: Duty type S3

- ΔTc – Operation time at constant load

- ΔT0 – Time de-energized and at rest

- Cyclic duration factor = ΔTc/T

4.2 The duty type S4

Intermittent periodic duty with starting

Definition: The duty type S4 is defined as a sequence of identical duty cycles, each cycle including a significant starting time, a time of operation at constant load and a time de-energized and at a rest.

A complete designation provides the abbreviation of the duty type followed by the indication of the cyclic duration factor, by the moment of inertia of the motor JM and by the moment of inertia of the load JL, both referred to the motor shaft (S4 20% JM = 0.15 kg m2 JL = 0.7 kg m2).

Figure 5 – Intermittent periodic duty with starting: Duty type S4

- ΔT* – Starting/accelerating time

- ΔTc – Operation time at constant load

- ΔT0 – Time de-energized and at rest

- Cyclic duration factor = (ΔT* + ΔTc)/ T

4.3 The duty type S5

Intermittent periodic duty with electric braking

Definition: The duty type S5 is defined as a sequence of identical duty cycles, each cycle consisting of a starting time, a time of operation at constant load, a time of electric braking and a time de-energized and at a rest.

A complete designation refers to the duty type and gives the same type of indication of the previous case.

Figure 6 – Intermittent periodic duty with electric braking: Duty type S5

- ΔT* – Starting/accelerating time

- ΔTc – Operation time at constant load

- ΔTf – Time of electric braking

- ΔT0 – Time de-energized and at rest

- Cyclic duration factor = (ΔT* + ΔTc + ΔTf)/ T

4.4 The duty type S6

Continuous-operation periodic duty

Definition: The duty type S6 is defined as a sequence of identical duty cycles, each cycle consisting of a time of operation at constant load and a time of operation at no-load. There is no time de-energized and at rest.

A complete designation provides the abbreviation of the duty type followed by the indication of the cyclic duration factor (S6 30%).

Figure 7 – Continuous-operation periodic duty: Duty type S6

- ΔTc – Operation time at constant load

- ΔT0 – Operation time at no load

- Cyclic duration factor = ΔTc/ΔT0

4.5 The duty type S7

Continuous-operation periodic duty with electric braking

Definition: The duty type S7 is defined as a sequence of identical duty cycles, each cycle consisting of a starting time, time of operation at constant load and a time of electric braking. There is no time de-energized and at rest.

A complete designation provides the abbreviation of the duty type followed by the indication of both the moment of inertia of the motor JM and the moment of inertia of the load JL (S7 JM = 0.4 kg m2 JL = 7.5 kg m2).

Figure 8 – Continuous-operation periodic duty with electric braking: Duty type S7

- ΔT* – Starting/accelerating time

- ΔTc – Operation time at constant load

- ΔTf – Time of electric braking

- Cyclic duration factor = 1

4.6 The duty type S8

Continuous-operation periodic duty with related load / speed

Definition: The duty type S8 is defined as a sequence of identical duty cycles, each consisting of a time of operation at constant load corresponding to a predetermined speed of rotation, followed by one or more times of operation at other constant loads corresponding to different speeds of rotation.

There is no time de-energized and at rest.

A complete designation provides the abbreviation of the duty type followed by the indication of the moment of inertia of the motor JM and by the moment of inertia of the load JL, together with the load, speed and cyclic duration factor, for each speed condition (S8 JM = 0.7 kg m2 JL = 8kgm2 25kW 800rpm 25% 40kW 1250rpm 20% 25 kW 1000 rpm 55%).

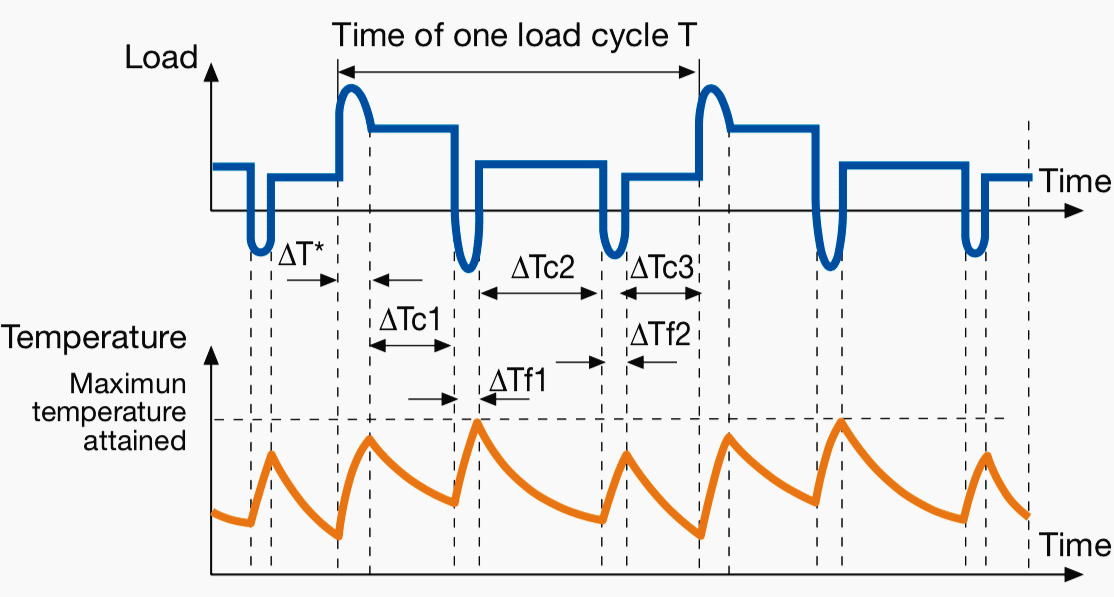

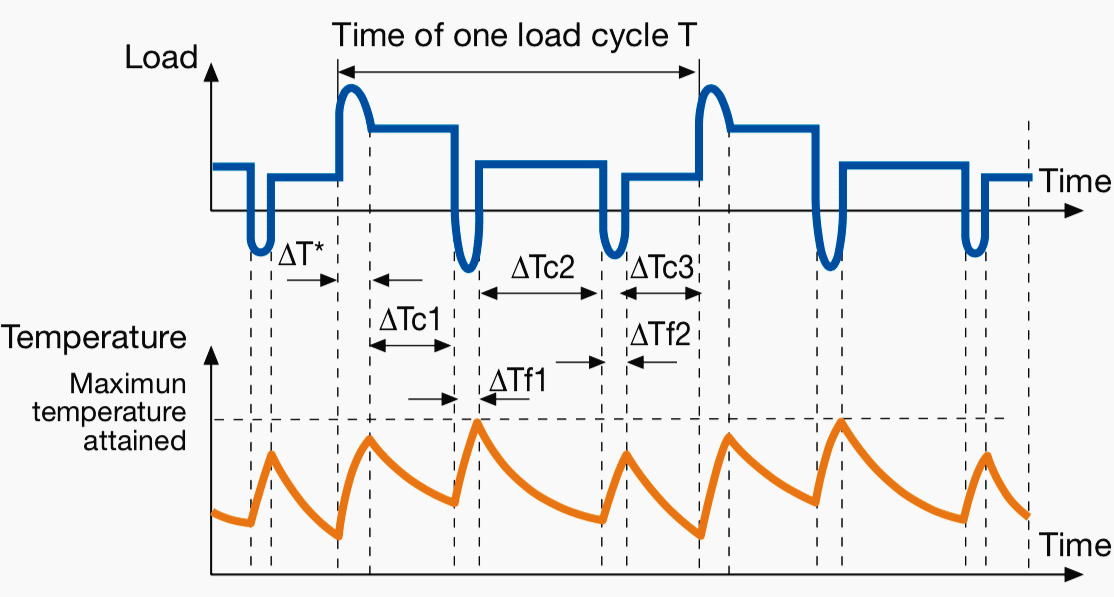

Figure 9 – Continuous-operation periodic duty with related load/speed: Duty type S8

- ΔT* – Starting/accelerating time

- ΔTc1; ΔTc2; ΔTc3 – Operation time at constant load

- ΔTf1; ΔTf2 – Time of electric braking

- Cyclic duration factor = (ΔT*+ΔTc1)/T; (ΔTf1+ΔTc2)/T; (ΔTf2+ΔTc3)/T

5. Non-periodic duty (type S9)

Duty with non-periodic load and speed variations

For a motor suitable to this duty type, the rating at which the machine may be operated non-periodically is specified. This class of rating corresponds to the duty type whose appropriate abbreviation is S9.

Definition: The duty type S9 is defined as a duty in which generally load and speed vary non-periodically within the permissible operating range. This duty includes frequently appplied overloads which may greatly exceed the reference load.

Figure 10 – Duty with non-periodic load and speed variations: Duty type S9

- ΔT* – Starting / accelerating time

- ΔTs – Time under overload

- ΔTc – Operation time at constant load

- ΔTf – Time of electric braking

- ΔT0 – Time de-energized and at rest

6. Duty with discrete constant loads and speeds (type S10)

For a motor suitable to this duty type, the rating at which the machine may be operated with a specific number of discrete loads for a sufficient time to allow the machine to reach thermal equilibrium is specified.

The maximum permissible load within one cycle shall take into consideration all parts of the machine (the insulation system, bearings or other parts with respect to thermal expansion).

This class of rating corresponds to the duty type whose appropriate abbreviation is S10.

Definition: The duty type S10 is defined as the operation characterized by a specific number of discrete values of load maintained for a sufficient time to allow the machine to reach thermal equilibrium. The minimum load during a duty cycle may have value zero and be relevant to a no- load or rest condition.

A complete designation provides the abbreviation of the duty type followed by the indication of the per unit quantities p/Δt for the partial load and its duration, and by the indication of the per unit quantity TL which represents the thermal life expectancy of the insulation system related to the thermal life expectancy in case of duty type S1 with rated output, and by the quantity r which indicates the load for a time de-energized and at rest (S10 p/Δt = 1.1/0.4; 1/0.3; 0.9/0.2; r/0.1 TL = 0.6).

Figure 11 – Duty with discrete constant loads and speeds: Duty type S10

Where:

- ΔΘ1; ΔΘ2; ΔΘ2 – Difference between the temperature rise of the winding at each of the various loads within one cycle and the temperature rise based on duty cycle S1 with reference load

- ΔΘref – Temperature at reference load based on duty type S1 t1; t2; t3; t4: time of a constant load within a cycle P1; P2; P3; P4: time of one load cycle

(Pref: reference load based on duty type S1)

7. Duty for equivalent loading

For a motor suitable to this duty type, the rating, for test purposes, at which the machine may be operated at constant load until thermal equilibrium is reached and which results in the same stator winding temperature rise as the average temperature rise during one load cycle of the specified duty type.

This class of ratings, if applied, corresponds to the duty type designated “equ”.

Suggested Course – The Essentials of Rotating Electrical Machines: AC & DC Electric Motors and Generators

The Essentials of Rotating Electrical Machines: AC & DC Electric Motors and Generators

Reference // Three-phase asynchronous motors Generalities and ABB proposals for the coordination of protective devices

s1 to s9

What parameter we require to estimate current as per duty cycle. Please elaborate.

THANKS FOR FULL EXPLANATION

sir, what is best Duty Types (Load Cycle) Of A Three-Phase Asynchronous Motors for EOT cranes for continuous operations (heavy duty) with 2-stage(pole-changing).

thanks , best regards

Good Explanation. Thank you

well defined

Hi,

What is the recommended duty type for Axial Flux PM motor for 150 Kmph high speed 2-Wheeler…???

Please send the technical article regularly

Grazie mille Edvard ! Mi piacciono molto i tuoi articoli. Li utilizzo a scuola con i miei studenti.

This is really a very helpful article regarding motor duty. To the point description.

Highly appreciated.

Thanks.

Dear sir,

What is the recommended duty type for induction motor connected to VFD?

Hello, I am from Iran. For thirty years now, I have been in charge of storing and remodeling the Samen Pharmaceutical Company in Mashhad. I used your information.

Hi, my appilcation matches S3, but if I using VFD, do I need to look for S3 75% as well??

Great work & an example/motivation for me to contribute my expertise so that anyone may benefit from this. I have learnt alot through this group.

Hope & pray this will continue

Edvard Csanyi.

Excelente your work.great profissional.

My admiration.

Kind

Joe Maria

Thank you Jose!

Excelente definiciones claras y precisas.