Understand, simplify and automate the process

Following the USA Principle is a good first step in any automation project.

The USA Principle is a common sense approach to automation projects. Similar procedures have been suggested in the manufacturing and automation trade literature, but none has a more captivating title than this one.

USA stands for:

- Understand the existing process

- Simplify the process

- Automate the process.

It may turn out that automation of the process is unnecessary or cannot be cost justified after it has been simplified.

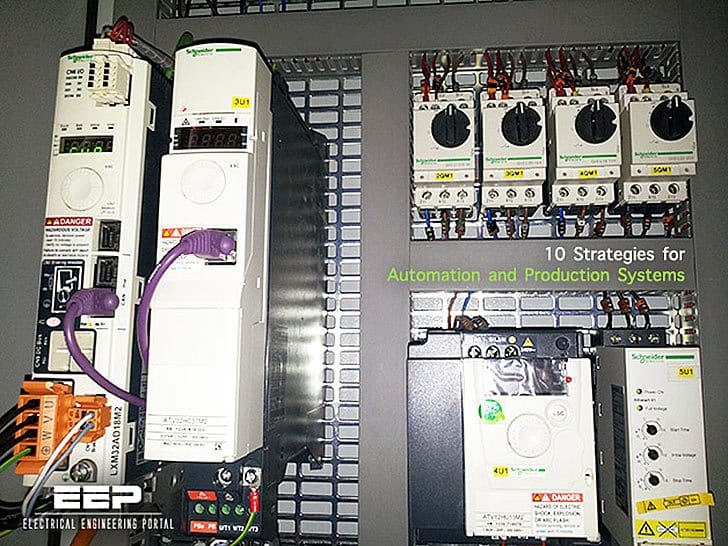

These ten strategies seem as relevant and appropriate today as they did in 1980. We refer to them as strategies for automation and production systems because some of them are applicable whether the process is a candidate for automation or just for simplification.

1. Specialization of operations

The first strategy involves the use of special-purpose equipment designed to perform one operation with the greatest possible efficiency.

This is analogous to the concept of labor specialization, which is employed to improve labor productivity.

2. Combined operations

Production occurs as a sequence of operations.

Complex parts may require dozens, or even hundreds, of processing steps. The strategy of combined operations involves reducing the number of distinct production machines or workstations through which the part must be routed.

Since each machine typically involves a setup, setup time can usually be saved as a consequence of this strategy. Material handling effort and non-operation time are also reduced.

Manufacturing lead time is reduced for better customer service.

3. Simultaneous operations

A logical extension of the combined operations strategy is to simultaneously perform the operations that are combined at one workstation. In effect, two or more processing (or assembly) operations are being performed simultaneously on the same workpart, thus reducing total processing time.

4. Integration of operations

Another strategy is to link several workstations together into a single integrated mechanism, using automated work handling devices to transfer parts between stations. In effect, this reduces the number of separate machines through which the product must be scheduled.

With more than one workstation, several parts can be processed simultaneously, thereby increasing the overall output of the system.

5. Increased flexibility

This strategy attempts to achieve maximum utilization of equipment for job shop and medium volume situations by using the same equipment for a variety of parts or products. It involves the use of the flexible automation concepts.

6. Improved material handling and storage

A great opportunity for reducing nonpro-ductive time exists in the use of automated material handling and storage systems.

Typical benefits include reduced work-in-process and shorter manufacturing lead times.

7. On-line inspection

Inspection for quality of work is traditionally performed after the process is completed. This means that any poor quality product has already been produced by the time it is inspected. Incorporating inspection into the manufacturing process permits corrections to the process as the product is being made.

This reduces scrap and brings the overall quality of product closer to the nominal specifications intended by the designer.

8. Process control and optimization

This includes a wide range of control schemes intended to operate the individual processes and associated equipment more efficiently. By this strategy, the individual process times can be reduced and product quality improved.

9. Plant operations control

Whereas the previous strategy was concerned with the control of the individual manufacturing process, this strategy is concerned with control at the plant level. It attempts to manage and coordinate the aggregate operations in the plant more efficiently.

Its implementation usually involves a high level of computer networking within the factory.

10. Computer-integrated manufacturing (CIM)

Taking the previous strategy one level higher, we have the integration of factory operations with engineering design and the business functions of the firm.

CIM involves extensive use of:

- Computer applications,

- Computer data bases, and

- Computer networking throughout the enterprise.

Conclusion

The ten strategies constitute a checklist of the possibilities for improving the production system through automation or simplification. They should not be considered as mutually exclusive.

For most situations, multiple strategies can be implemented in one improvement project.

Reference: Industrial Automation / Course Notes – David O’Sullivan

Hi! we already apply your suggestions, thanks for sharing the info – Greetings from Mexico.

Hello I am an electrical engineer and manufacturer of electrical panels

Would love to collaborate with you

I’m from Israel