Degradation and breakdown

The most frequent failure in electrical equipment is the degradation and breakdown (flashover) of the insulation. Electrical insulation can be liquid or solid, organic or inorganic. Organic insulation material consists of: enamels, varnishes, resins, or polymers that are applied to the steel surface to provide high inter-laminar (between windings) resistance as found on most air-cooled machinery and some oil-immersed transformers.

Larger transformers are oil-filled with pure mineral oil to provide higher insulation capability and more effective heat dissipation when equipped with external radiators, fans and pumps. Physical insulation inside these transformers is often in the form of oil-impregnated paper wrapped around the conductors.

Inorganic insulation material can include a combination of:

- Magnesium oxide,

- Silicates,

- Phosphates, and

- Ceramic powder.

This type of insulation is usually heat-treated intothe surface of the steel and is less common than organic insulation.

No matter what the type of insulation, the two most common contributing factors in insulation failure are moisture and heat.

Excessive Moisture

On air-cooled electrical machinery, the moisture content of the air is very important. With aging of the insulation, small hairline cracks will appear in the insulation. Moisture will seep into these cracks and allow an electrical path to short-circuit between adjacent turns of wire.

On oil-cooled machinery (i.e., transformers), moisture can only be detected by regular oil samples. Moisture will be sucked into the oil via the oil expansion air vent, through the continuous process of transformer heating and cooling cycles.

Special air dryers (i.e., Drycol) and absorbents can assist in decreasing the rate the moisture is absorbed into the oil.

With oil-filled transformers it isimportant to note that very little moisture content is required to tremendously decrease the insulation value of the oil. Only 30 parts of water per million parts of oil can decrease the insulation capability by 50%.

Excessive Temperature

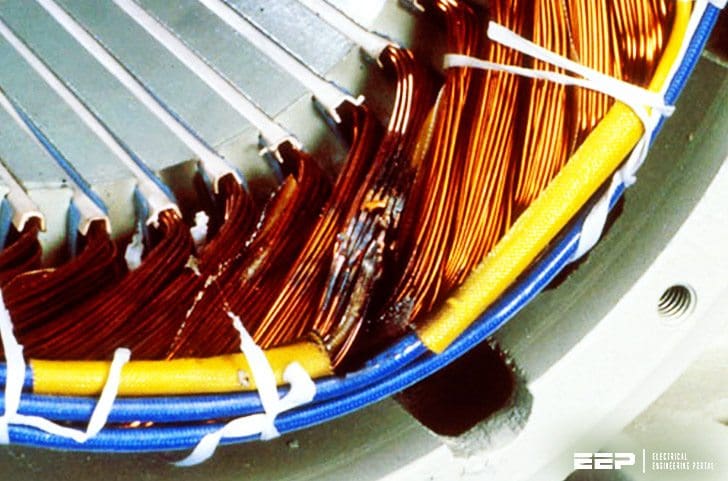

On air-cooled electrical machinery, prolonged high temperature causes thermal aging. This causes the insulation to become brittle. Eventual failure can occur due to moisture penetration as just discussed, or by physical contact of conductors.

As an example – for a standard 65°C (temperature rise) rated insulation the loss of life increases from 0.001% per hour at 100°C to 0.05% per hour at 140°C and 1.0% per hour at 180°C.

Translated into time span the expected insulation life would be 11.4 years at 100°C, 83 days at 140°C, 100 hours at 180°C.

It is fairly clear to see the importance of maintaining a daily record of the operating temperatures and ensuring that all electrical equipment are kept at low ambient temperatures.

Reference: Science and Reactor Fundamentals and Electrical – CNSC Technical Training Group

Very helpful and informative paper for Electrical Maintenance Engineers.

Paper is most commonly used as primary inter turn insulation in Transformer windings. Papers, being hygroscopic in nature, contains moisture in it ; but for inter-turn insulation failure, a crack in paper insulation may allow moisture to bridge the crack — which leads to inter-turn short circuit.

Pl. clarify why the moisture already present in paper ( at a lower Temp.) does not normally behave like this.

very good information but how i can down load the article in pdf thank you

You can find “Get PDF” at left side bar and click it.

Cheers,

where is the left side bar for “get pdf”

Good analysis for the observed failures. Informative article on the subject.

literature about any mentioned topic, provided by you is sufficient to solve the problems also good literature to convey the relative students.