Light Control / Energy Savings

Lighting systems in industrial facilities can represent an attractive savings opportunity, especially if lighting systems have not been upgraded or maintained in the past five years.

The most cost-effective approach for lighting energy savings is to address the following three issues, in order:

- Turn off lights during times when they are not needed

- Reduce light levels to match the requirements for the tasks being performed in the area

- Replace less efficient lamps, ballasts, or fixtures with more efficient sources

These light level recommendations are typically described as ranges of footcandles, the footcandle being a quantity of light measured at a horizontal or vertical surface. Light output of a fixture is usually published in lumens.

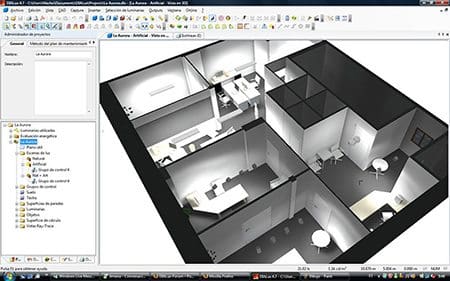

Many manufacturers of lamps and lighting systems offer software tools to aid in designing new systems, or in evaluating changes to existing systems.

Let’s see above mentioned essentials which obviously you can not deny…

1. Lighting controls work better than people

While “turn-off-the-light” programs have been widely utilized in all types of facilities, sophisticated lighting control systems have proven to be much more cost-effective.

Lighting system controls that utilize microprocessors and specially-designed remote-operated circuit breakers are much more effective. These devices can be programmed to accommodate complicated shift configurations, including nights, weekends, and holidays.

They also include simple override features for temporary or unusual work schedules. In addition, these systems can be monitored and controlled remotely using standard web-browser software packages, and they can interface with other control devices such as motion sensors or photocells.

2. Light levels decline with age of the lighting system

Several factors contribute to this decline. Lamps, including fluorescent and high-intensity discharge sources like high-pressure sodium and metal halide, experience Lamp Lumen Depreciation, or LLD. The LLD is typically less than 1.0, indicating that average lamp light output at some point in the future is less than light output of a new lamp.

Ballast Factor, or BF, is yet another commonly used factor. BF is also a published value that is a function of the type of ballast used to control the arc characteristics of fluorescent and HID lighting systems.

The designer usually applies these factors to the rated light level output of a lighting system, in order to estimate the number of fixtures required to provide the desired light level – not at initial installation, rather at some designated point in the future.

For example,

# fixtures = total required lumens / initial lumens / fixture / (LLD · LDD · BF)

3. Lighting designers need to know the facility’s lamp replacement practices

Manufacturers publish the “rated life” expectancy of a given lamp. This value, usually given in thousands of hours, is not a guarantee that every lamp will extinguish at the same rated-life time. In fact, the “rated life” is a statistical value indicating the point at which halfof the lamps of a representative sample will burn out.

Some lamps will fail well shy of the rated life; others may last beyond the rated life.

The facility’s lamp replacement practices usually fall into one of two categories:

- Replace individual lamps as they fail (“spot replacement”)

- Replace all lamps at a predetermined point in time, even though many of those lamps are still burning (“group replacement”)

Group replacement runs counter to common sense for most people – if it ain’t broke, don’t fix it. That’s why spot replacement is the most common practice by far. There is, however, a sound reason for considering the group-replacement strategy: Economics.

If the lighting designer knows, for example, that a facility will adopt the practice of group replacement, the designer can utilize fewer light fixtures at the outset. That’s because the lamps replaced before their end of life produce considerably more lumens than those allowed to burn to failure.

The designer can use a higher LLD in the initial light fixture calculations to achieve the same target footcandle level.

Fewer light fixtures means lower energy costs attributable to lighting, and less heat for the building’s air conditioning system.

Labor costs have also been shown to be lower for group replacement as compared to spot replacement. Group replacement can be scheduled to occur during unoccupied times; set up and take down costs are reduced; the cost per lamp itself can be lower with large-quantity purchases.

Reference // Electrical Energy Management Bill Brown, P.E., Square D Engineering Services

detailed information about LED required. How these system is efficient w.r.t. the other lighting system. technical Comparison. lumen package, DLOR, life, CCTs, CRI, Lumen depreciation, UV, etc.,

More article of lighting please.

Nice article.

I’m enjoying it very well

Lighting with Led technology and the use of electronic ballasts is the most recente trend to save energy in lighting installations.

In house Energy saving Idea

Nice Article, I am interested in news letters