Energy Saving Potential

Efficiencies of fan systems vary considerably across impeller types. The average energy saving potential in these systems in the U.S. manufacturing industry is estimated at 6%. For optimal savings and performance, it is recommended that a systems approach is used.

In the following, energy saving opportunities for fan systems are presented.

- Minimizing pressure

- Control density

- Fan efficiency

- Proper fan sizing

- Adjustable speed drives (ASDs)

- High efficiency belts (cogged belts)

1. Minimizing pressure

Pressure offers greater opportunities to reduce energy costs. A system with good airflow characteristics (duct and sizes optimized), matched with the proper control device, pressure monitors, and variable-frequency drives, can help manage system pressure.

Most baghouses or other collection devices will have varying pressure drops over the life of the system. Bags are generally more efficient at higher pressure drops, but then use more energy.

As ASDs become less expensive they are now being found on many installations. Be mindful of duct inefficiencies and fan system effects (elbows at inlets and outlets, etc.) These shortcuts increase static pressure and operating costs for the life of the system.

2. Control density

Temperature, moisture, molecular weight, elevation, and the absolute pressure in the duct or vessel affect the density of the transporting gas. A density change may affect the hardware requirements for the system.

This may be more than offset by reduced costs for smaller ducts, control devices, and fans (as well as lower the value for volumetric flow rate in the equation).

3. Fan efficiency

The key to any design is proper fan selection. The design of the fan and its blade type can affect efficiency and power requirements significantly. Laboratory-measured peak fan efficiency may not be the most stable point of operation.

The designer must consider both curves when selecting the best fan and operating point to optimize reliability and power usage. Fan type may dictate proper selection. Airfoil wheels, while more efficient, may not be a good choice when handling particulate laden air.

4. Proper fan sizing

Most of the fans are oversized for the particular application, which can result in efficiency losses of 1-5%. However, it may be more cost-effective to control the speed than to replace the fan system.

5. Adjustable speed drives (ASDs)

Significant energy savings can be achieved by installing adjustable speed drives on fans. Savings may vary between 14 and 49% of fan system energy use when retrofitting fans with ASDs.

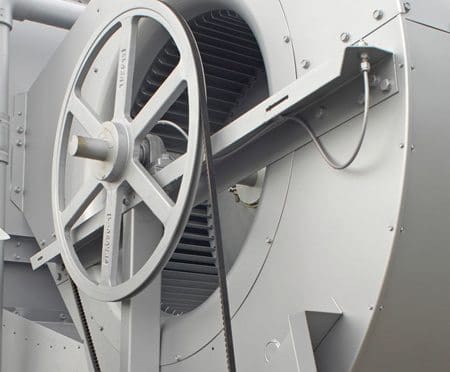

6. High efficiency belts (cogged belts)

Belts make up a variable, but significant portion of the fan system in many plants. Standard V-belts tend to stretch, slip, bend and compress, which lead to a loss of efficiency.

Typical payback periods will vary from less than one year to three years.

Definitions of Fan Power and Fan Efficiency for buildings

Simon talks about Fan Efficiency, Fan Input Power and regulations that are associated with this. He explains the reasons for the need of high-efficiency fans, regulated through international standards like ISO 12759 or the Minimum Energy Performance Standards (MEPS) and In From The Cold Strategy locally in Australia.

He also outlines standards of fan efficiency. A definition for this is currently being negotiated in Australia.

Cant see this video? Click here to watch it on Youtube.

Reference // Industrial Energy Audit Guidebook: Guidelines for Conducting an Energy Audit in Industrial Facilities – Ali Hasanbeigi, Lynn Price

Is there is any booklet concerning to energy saving on industrial equipments like Transformers, Motors?

(Other than V.F.D’s)?

Hi sir,

Info is very useful. Best article.