Lockout operations

The lockout operations or safety procedures are precisely and clearly defined operations, the aim of which is always to ensure that situations are, and remain, safe. This will enable people to work on all or part of an installation (or a device), with return to operation (removal of lockout) only being possible by the intentional, concerted action of those responsible.

Lockout consists of a number of essential steps //

… and before any work carried out you must have //

1. Separation

This consists of “de-energising” all power, control and monitoring, and emergency circuits by breaking with visible or positive contact indication.

Go back to lockout operations ↑

2. Immobilisation

This is carried out by mechanical means using padlocks or locks. It prevents any intentional or accidental operation of the immobilised device. It should be noted that profiled keys (triangle, square, etc.) are not permitted for this function.

Go back to lockout operations ↑

3. Dissipation (or setting to the lowest energy level)

This consists of discharging the capacitors. For maximum safety, it includes the earthing and short-circuiting of the conductors.

It is compulsory above 500 V, but is not compulsory below this level (LV range) unless there is a risk of induced voltages, capacitive effects (capacitors or considerable lengths) or a risk of backfeed.

Go back to lockout operations ↑

4. Checking the voltage

This must be carried out as close as possible to the location of the operation, with a standard device for “detecting the absence of voltage” (En 61243-5) between all the conductors including the neutral and between those conductors and earth.

This systematic step must be accompanied by the means required for informing people “not working and working” on the electrical equipment.

Go back to lockout operations ↑

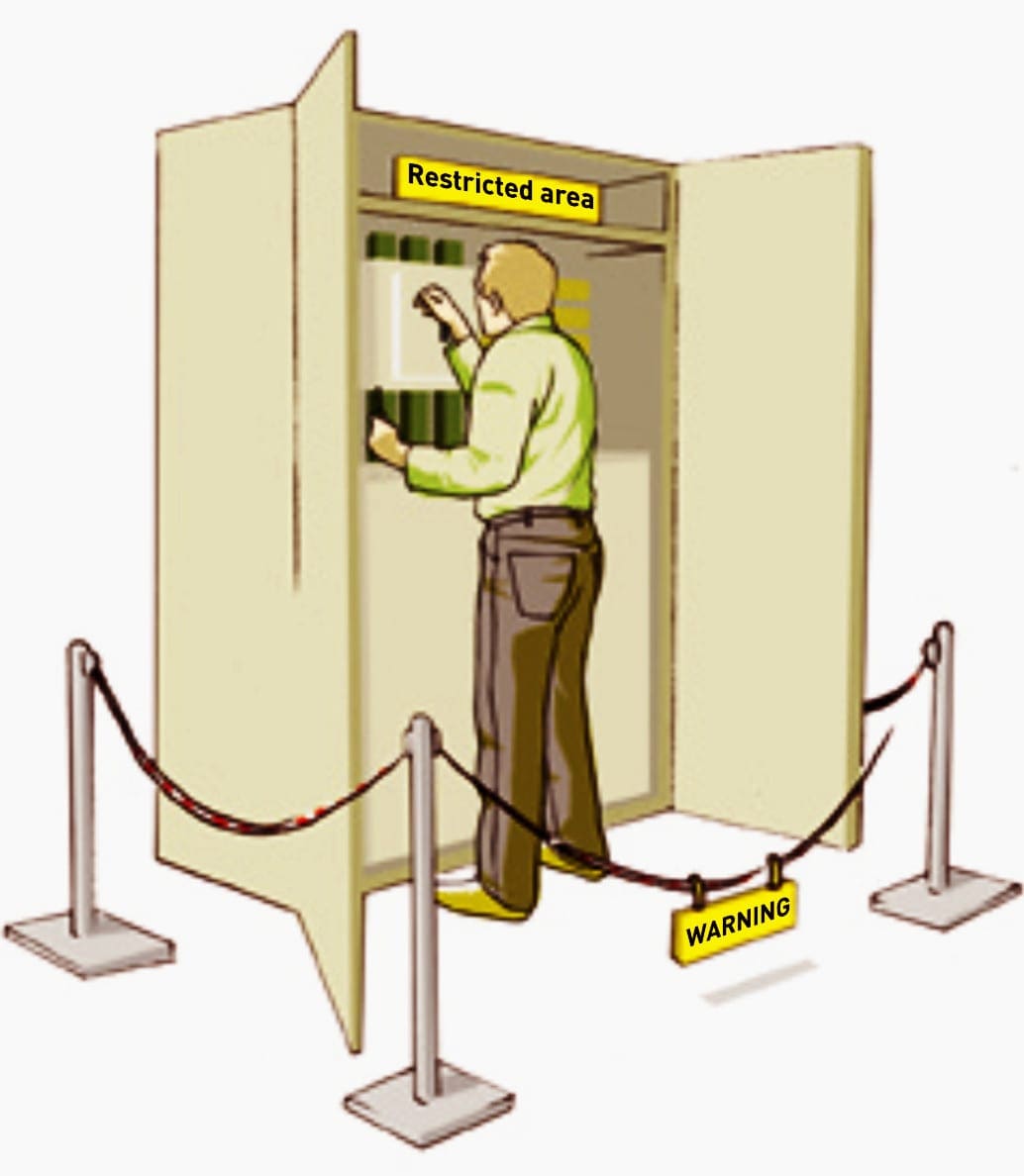

5. Signaling

This consists of clear, precise and permanent information on the lockout status of the installation. It may be necessary to mark out the area.

Go back to lockout operations ↑

6. Identification

This must enable targeted work, with no ambiguity, to be carried out on the device or part of the installation concerned. To this end, up to date wiring diagrams, geographical location maps, markings, etc., must be available.

Go back to lockout operations ↑

Why locking?

Only locking can ensure the immobilised state. Several locks are often used together:

- To order the sequence of operations (order of commands)

- To make the operations interdependent and alternative (for example, supply inversion)

- To necessitate the simultaneous action of several people (increased safety)

When the key is released by the first lock and thus allows a second lock to be operated, this is referred to as interlocking with key transfer.

The locking sequence may also require the release of several keys: in this case a device with multiple locks enables the first key, referred to as the “mother key”, which must remain captive, to release several keys, referred to as daughter keys.

Go back to lockout operations ↑

Before any work carried out you must have:

Training and qualification

A special theoretical and practical training programme, representative of the work to be carried out, must be drawn up to develop and maintain the ability of qualified or well-informed people to carry out electrical work and in particular live work.

At the end of the training, the participant must be awarded a certificate. The aptitude level is validated by accreditation which must be renewed if the person changes job or line manager, has a long break from work, medical restrictions, clear lack of aptitude, or if there are significant changes to work methods or installations.

Go back to lockout operations ↑

Accreditations

Accreditation consists of the recognition by the employer of a person’s aptitude to perform the tasks assigned to him/her totally safely. A written certificate of accreditation, including the identification and approval of the parties and the code of the level of accreditation, must be given to the employee. This certificate does not however release the employer from his/her responsibilities.

The accreditation level must be appropriate to the work to be carried out: it will be different for example for the painter who is working in a transformer room and the electrician working on the transformer itself.

But it is essential that they have both received training appropriate to the risks incurred to themselves and to others.

For example, the person who carries out the cleaning on a test platform must be accredited accordingly.

Go back to lockout operations ↑

Authorisations

Whatever work is undertaken, the lockout operation itself must form the subject of written documents and above all confirmation that these documents have been safely received by the addressee. Messages sent electronically (faxes, emails) must be subject to appropriate precautions regarding the guarantee of receipt and their being understood.

A reply message with the identification number of the original message is compulsory. The read receipt is not sufficient. The lockout certificate will be used for this purpose. It must be sent to the works supervisor, marked with the date and time, and must incorporate a section for notification of the end of work. Other documents may be used.

The list given here is not exhaustive: work order, operation sheet, instruction, notice of requisition, certificate of separation from the public distribution network, etc.

Go back to lockout operations ↑

Reference // Operating functions – The power book by Legrand

Hello very kind Engineer, beautiful technical article. I used it for a safety lesson. My students are very interested. Thanks a lot See you soon.

Pasquale

Thank you Pasquale.

I want to undergo Electrical training with you,I’m a Nigerian, I live in Abuja the capital city of Nigeria, I have experience in Electrical want to learn more with you about substation

NO COMPROMISE.

Every Electrical Engineer irrespective of the Operation or Maintenance of LV, MV & HV System must kept in mind for Lockout to ensure the safety of Men & Material.

The Technician should be wearing gloves.

Fantastic, keep on informing.

great