Electrically safe work and NFPA 70E

Equipment that has been deenergized and verified as such is said to be in an electrically safe work condition. Article 120.1 of NFPA 70E outlines six steps that must be followed to insure that employees are working in an electrically safe work condition.

Six safety steps to become a safeaholic electrician:

Step 1 // – Check, check and check

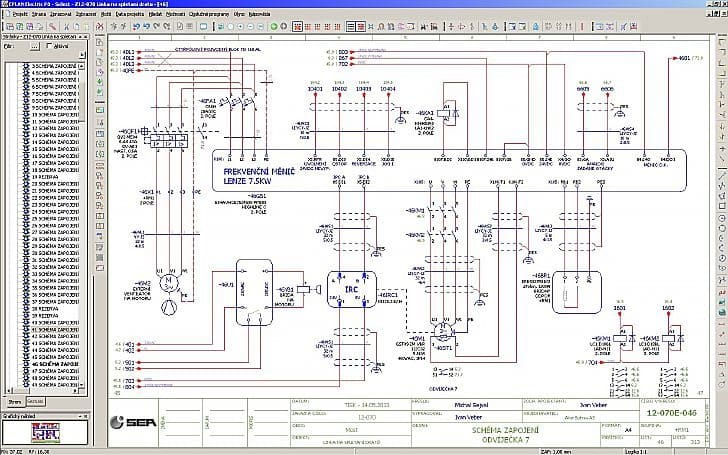

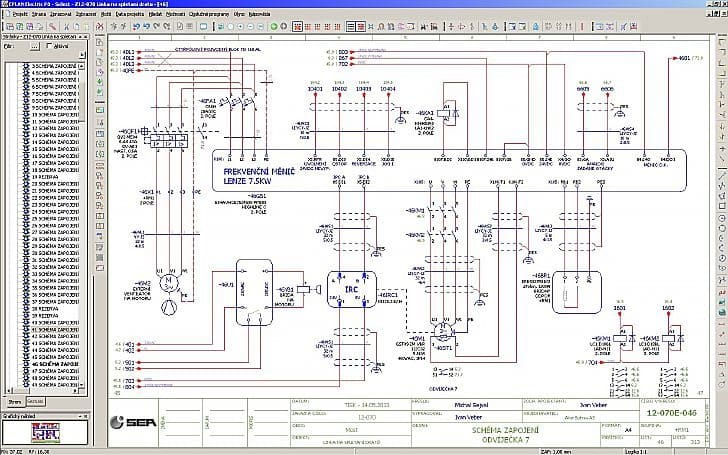

Determine all possible sources of electrical supply to the specific equipment. Check applicable up-to-date drawings, diagrams, and identification tags.

Step 2 // – Open disconnect devices

After properly interrupting the load current, open the disconnecting device(s) for each source.

Step 3 // – Visual verify

Wherever possible, visually verify that all blades of the disconnecting devices are fully open or that drawout-type circuit breakers are withdrawn to the fully disconnected position.

Step 4 // – LOTO

Apply Lockout / tagout (LOTO) devices in accordance with a documented and established policy.

Step 5 // – Make sure is deenergized

Use an adequately rated voltage detector to test each phase conductor or circuit part to verify they are deenergized. Test each phase conductor or circuit part both phase-to-phase and phase-to-ground.

Before and after each test, determine that the voltage detector is operating satisfactorily.

Step 6 // – Check unthinkable and ground!

Where the possibility of induced voltages or stored electrical energy exists, ground the phase conductors or circuit parts before touching them. Where it could be reasonably anticipated that the conductors or circuit parts being deenergized could contact other exposed energized or circuit parts, apply ground connecting devices rated for the available fault duty.

It is important to note that a safe work condition does not exist until all 6 steps are complete. During the process of creating the electrically safe work condition, the appropriate PPE must also be utilized.

Working on energized equipment Although the best practice is to always work on deenergized equipment, OSHA and NFPA do recognize that in some circumstances it may create an additional hazard or be infeasible to deenergize.

OSHA 2CFR 110.333 (a)(2) states:

Energized parts.

If the exposed live parts are not deenergized (i.e., for reasons of increased or additional hazards or infeasibility), other safety-related work practices shall be used to protect employees who may be exposed to the electrical hazards involved. Such work practices shall protect employees against contact with energized circuit parts directly with any part of their body or indirectly through some other conductive object…

Electrical tasks such as troubleshooting and testing for the presence of voltage, current, etc., can only be done while equipment is energized. In these instances, work on energized equipment is allowed, but workers must follow safe work practices and use the appropriate personal protective equipment (PPE).

Other exceptions that allow work on energized equipment include:

- Life-support equipment

- Emergency alarm systems

- Hazardous area ventilation equipment

Deenergizing these types of equipment could increase or create additional hazards. A mistake often made is confusing infeasibility with inconvenience. For example, meeting a manufacturing production schedule does not qualify as infeasible. It may be very inconvenient but it still does not authorize working on energized equipment.

Electrical workers must also be trained and specially “qualified” to work on energized equipment, and the specific equipment to be serviced.

As a worker, you may be qualified for some tasks and unqualified for other. Knowing the difference between the two can save your life.

Reference // Electrical Safety Hazards Handbook – Littelfuse (Download)

need more info about your institute thanks

This article could be updated to reflect the 2021 changes to NFPA 70E 120.5 which allows for the application of an approved absence of voltage tester that conforms to the design and operating requirements of UL 1436.

Good to always be safe when working with electrical. Mr. Edvard, this is very good tips on safety.

MR EDVARD SIR,

ANY SHORT NOTE ON HIGH VOLTAGE COURSE FOR MARINERS?

THANKS & REGARDS,

MUKESH

Great article on electrical safety and other electrical engineering topics

rule one in this country DON’T WORK on life or near life parts .

Gerard van Zeijl

Santon circuit breaker services

I would be very concerned if any of my guys used a non contact voltage indicator (such as shown in photo 4) to prove dead before working on electrical systems.

There are some sound principles here but it does illustrate how we all need to use caution with internationally distributed information to ensure complying with national legislation and standards.

Having said all that I do enjoy reading Edvard’s articles.

The use of a non-contact voltage stick is akin to playing Russian roulette with your life. These devices are not designed to “prove electrically dead” and I believe the manufacturers of these devices make no such claims either.

I have used one these sticks to check both ends of a resin joint (120mm Copper L1 & L2 distribution cores carrying 650V ac) after switching back on. Even though the joint was good with both dead and live checks using appropriate calibrated test equipment verifying that, on site one end of the joint lit up the stick whilst the other did not.

Please be careful and use the correct proven quality test equipment to prove dead before touching.

Very good information regarding safe working in electrical

Nice.about transmission and distribution

Well it’s a nice site for any precautions measures, for any may know other thing bit not all for we sometimes pretend to everything bit it takes knowledge