1. Start from the need: what do I want to measure?

A single electric parameter or all the electric parameters

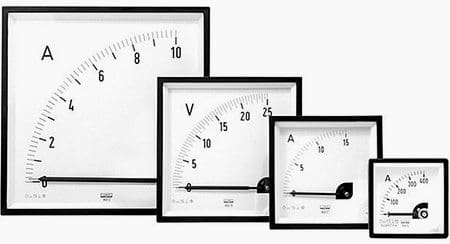

There are different product families on the market: instruments that measure a single electric parameter (voltage, current, frequency, phase angle cosϕ), generally used in single phase systems, as instrumentation on the machine, and instruments that enable all the electric parameters to be measured and displayed, both for the single phase and in the three phase system.

This type of multifunction instrument is ideal in panels in which space is limited, in panels of substations and in main industrial panels.

If not only electric parameters need to be monitored but also energy consumption needs to be checked, measuring instruments that also include an active and reactive energy count have to be selected.

2. Selecting the measuring system

Single parameter, multifunction, analogue or digital instrument

The instrument should be selected according to the type of distribution system. In a single-phase system, analogue and digital instruments are selected for measuring voltage, current, frequency and the power factor.

Choosing an analogue instrument ensure good reading stability, due to the mechanical inertia of the needle and the fact that the reader immediately knows whether the instrument is working normally or whether the reading is off-scale.

The analogue instrument indicates the point on the measuring scale in which it finds itself, showing the upper and lower limits.

In digital instruments this indication is not possible as the only reference is the reading of the value on the display, for example, of the current. Some measuring instruments have bar indicators that show the current level as a percentage of the set full scale.

Choosing a digital instrument guarantees better readability, also in poor lighting, specially for instruments with LED displays, and an immediate reaction to the measurement variation.

3. Sizing the system, choosing the CT

Sizing the measuring system starts with knowing the main parameters of the plant; in particular, starting from the characteristics of the protection switch, the type of distribution system, rated current, rated voltage and bar type can be known.

After the type of instrument has been defined that is most suitable for requirements, if the measurement is conducted through indirect insertion, the accessories of the measuring system such as current and voltage transformers must be chosen carefully.

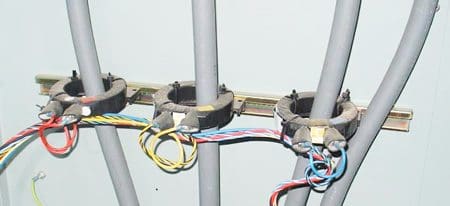

If an 800 A current has to be measured, in most cases the instrument cannot be connected directly to the line. A current transformer that is suitable for the application must therefore be selected. The chosen parameters of a current transformer are not only rated current, secondary current and power but also the type of assembly. Flexible and stiff cables or bars for carrying power can be installed in a power panel.

The transformers can be of different types, depending on the assembly system: a through cable or a cable with a wound primary, transformers for assembly on horizontal or vertical bars.

4. Cabling and wiring diagrams

Connecting analogue instruments is very simple; it in fact suffices to connect the phase and neutral cables to the instrument’s.terminal. Two cables fo the auxiliary supply must always be connected for digital instruments.

Multifunction instruments can be used in different distribution systems.

In multifunction instruments not only the cables connected to the measurement, but also the RS485 serial port and the analogue and digital outputs and inputs have to be cabled.

5. Protecting the instrument and earthing

In order to ensure that the instrument is properly protected, fuses must always be fitted to the supply cables of digital instruments and to the voltmeter measuring inputs.

Earthing the secondaries of the CTs ensures an earth connection if the transformer develops a fault and does not affect the measurement. If there is a great potential difference between neutral and earth, this could affect the measurement negatively, in the case of instruments with measuring inputs that are not galvanically insulated.

6. Setting digital instruments

Before digital instruments start operating they must be set with the parameters of the measuring system and the communication parameters. The main measuring parameters are the transformation ratios of the CTs and of the VTs, which are defined as the mathematical ratio between the nominal value and the value of the secondary;

For example, setting the transformation ratio of an CT CT3/100 with a secondary at 5 A means setting kCT = 100: 5 = 20

7. Troubleshooting during final testing

The main problems that arise during the test phase may be due to incorrect installation of the instruments and the accessories. Always check that the wiring complies with the instruction manual.

Errors during installation

The following errors are those that are most frequently committed when installing a measuring instrument:

- Inverting the secondaries of the CTs

- Inverting the phases of the current and voltage measuring inputs

- Failure to eliminate the short circuit of the secondaries of the CTs

- Setting an incorrect transformer ratio.

Reference: Practical guide to electrical measurements in low voltage switchboards – ABB (Download)

Tell me about the use of a voltage of 20 kV to 220 volts to protect the power transformer.

Thanks

Alizadeh

Article will be useful for engineers at site&project works

Good article to know the basics of selecting measurement instruments. It’s important to check the class of precision we will need depending of our application and for electronic meters others applications like reporting, logging and communications.

For an electronic industry of sophesticated production, how much should be the float voltage spec for test benches which works on ups CAN spec can be made Is it possible to get less than 1.2v ac float

Good Article