Energy Saving Opportunities

When considering energy-efficiency improvements to a facility’s motor systems, a systems approach incorporating pumps, compressors, and fans must be used in order to attain optimal savings and performance.

In the following, considerations with respect to energy use and energy saving opportunities for a motor system are presented and in some cases illustrated by case studies. Pumping, fan and compressed air systems are discussed in addition to the electric motors.

Potential energy-efficiency improvements:

- Motor management plan

- Maintenance program

- Using of energy-efficient motors

- Rewinding of motors

- Proper motor sizing

- Using Adjustable speed drives (ASDs)

- Power factor correction

- Minimizing voltage unbalances

1. Motor management plan

A motor management plan is an essential part of a plant’s energy management strategy. Having a motor management plan in place can help companies realize long-term motor system energy savings and will ensure that motor failures are handled in a quick and cost effective manner.

The Motor Decisions MatterSM Campaign suggests the following key elements for a sound motor management plan (CEE, 2007):

- Creation of a motor survey and tracking program.

- Development of guidelines for proactive repair/replace decisions.

- Preparation for motor failure by creating a spares inventory.

- Development of a purchasing specification.

- Development of a repair specification.

- Development and implementation of a predictive and preventive maintenance program.

2. Maintenance

The purposes of motor maintenance are to prolong motor life and to foresee a motor failure. Motor maintenance measures can therefore be categorized as either preventative or predictive.

Some of these measures are further discussed below. Note that some of them aim to prevent increased motor temperature which leads to increased winding resistance, shortened motor life, and increased energy consumption.

The purpose of predictive motor maintenance is to observe ongoing motor temperature, vibration, and other operating data to identify when it becomes necessary to overhaul or replace a motor before failure occurs.

The savings associated with an ongoing motor maintenance program could range from 2% to 30% of total motor system energy use.

3. Energy-efficient motors

Energy-efficient motors reduce energy losses through improved design, better materials, tighter tolerances, and improved manufacturing techniques. With proper installation, energy- efficient motors can also stay cooler, may help reduce facility heating loads, and have higher service factors, longer bearing life, longer insulation life, and less vibration.

The choice of installing a premium efficiency motor strongly depends on motor operating conditions and the life cycle costs associated with the investment.

In general, premium efficiency motors are most economically attractive when replacing motors with annual operation exceeding 2,000 hours/year. Sometimes, even replacing an operating motor with a premium efficiency model may have a low payback period.

According to data from the Copper Development Association, the upgrade to high-efficiency motors, as compared to motors that achieve the minimum efficiency as specified by the Energy Policy Act of 1992 can have paybacks of less than 15 months for 50 hp motors.

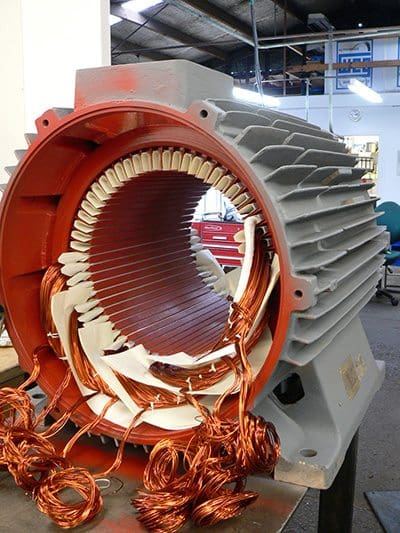

4. Rewinding of motors

In some cases, it may be cost-effective to rewind an existing energy-efficient motor, instead of purchasing a new motor. As a rule of thumb, when rewinding costs exceed 60% of the costs of a new motor, purchasing the new motor may be a better choice (CEE, 2007).

When repairing or rewinding a motor, it is important to choose a motor service center that follows best practice motor rewinding standards in order to minimize potential efficiency losses. Such standards have been offered by the Electric Apparatus Service Association (EASA).

When best rewinding practices are implemented, efficiency losses are typically less than 1% (EASA, 2003). Software tools such as MotorMaster+ can help identify attractive applications of premium efficiency motors based on the specific conditions at a given plant.

5. Proper motor sizing

It is a persistent myth that oversized motors, especially motors operating below 50% of rated load, are not efficient and should be immediately replaced with appropriately sized energy-efficient units. In actuality, several pieces of information are required to complete an accurate assessment of energy savings.

The efficiency of both standard and energy-efficient motors typically peaks near 75% of full load and is relatively flat down to the 50% load point. Motors in the larger size ranges can operate with reasonably high efficiency at loads down to 25% of rated load.

There are two additional trends: larger motors exhibit both higher full- and partial-load efficiency values, and the efficiency decline below the 50% load point occurs more rapidly for the smaller size motors.

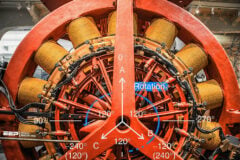

6. Using Adjustable speed drives (ASDs)

Adjustable-speed drives better match speed to load requirements for motor operations, and therefore ensure that motor energy use is optimized to a given application. As the energy use of motors is approximately proportional to the cube of the flow rate, relatively small reductions in flow, which are proportional to pump speed, already yield significant energy savings.

Adjustable-speed drive systems are offered by many suppliers and are available worldwide. Worrell et al. (1997) provides an overview of savings achieved with ASDs in a wide array of applications; typical energy savings were shown to vary between 7% and 60% with estimated simple payback periods for ranging from 0.8 to 2.8 years (Hackett et al., 2005).

7. Power factor correction

Power factor is the ratio of working power to apparent power. It measures how effectively electrical power is being used. A high power factor signals efficient utilization of electrical power, while a low power factor indicates poor utilization of electrical power.

The power factor can be corrected by minimizing idling of electric motors (a motor that is turned off consumes no energy), replacing motors with premium-efficient motors, and installing capacitors in the AC circuit to reduce the magnitude of reactive power in the system.

8. Minimizing voltage unbalances

A voltage unbalance degrades the performance and shortens the life of three-phase motors.

A voltage unbalance causes a current unbalance, which will result in torque pulsations, increased vibration and mechanical stress, increased losses, and motor overheating, which can reduce the life of a motor’s winding insulation.

An example of Effects of voltage unbalance on 5 hp motor:

| Characteristic | Performance | ||

| Average voltage | 230 | 230 | 230 |

| Percent unbalanced voltage | 0.3 | 2.3 | 5.4 |

| Percent unbalanced current | 2.4 | 17.7 | 40 |

| Increased temperature (ºC) | < 1 | 11 | 60 |

Voltage unbalances may be caused by faulty operation of power factor correction equipment, an unbalanced transformer bank, or an open circuit. A rule of thumb is that the voltage unbalance at the motor terminals should not exceed 1% although even a 1% unbalance will reduce motor efficiency at part load operation. A 2.5% unbalance will reduce motor efficiency at full load operation.

Another indicator for voltage unbalance is a 120 Hz vibration, which should prompt an immediate check of voltage balance (U.S. DOE-OIT, 2005b).

The typical payback period for voltage controller installation on lightly loaded motors in the U.S. is 2.6 years (U.S. DOE-IAC, 2006).

Reference: Industrial Energy Audit Guidebook: Guidelines for Conducting an Energy Audit in Industrial Facilities – Ali Hasanbeigi, Lynn Price

Espectacular sus informaciones sobre toda la parte eléctrica. Felicitaciones

Very good article

Power factor correction suggestion is truly incorrect. If you compensate the reactive power consumed by motor, it still consumes it, motor needs reactive power to create the magnatic field. Motor simply does not pull it from the grid, but from your capacitors, so nothing changes in the motor.

VFD does cut out unnecessary consumption and adapts to current needs, so it saves energy wastage, but the actual efficiency of the motor drops down significantly due to harmonics and low speeds.

I agree with you. Induction motors consume at low load, e.g. %60 and below loads. Low power factor doesn’t indicate poor utilization of electrical power. The power factor is only a result of the magnetic circuit.

Cabe lembrar que não basta substituir motores comuns por motores de alta eficiência, esta troca, por si só, não é garantia de melhorias de eficiência energética nos sistemas motrizes operando em processo industrial. É necessário entender que sistema motriz é motor mais carga acionada. Não se pode analisar o motor, de maneira isolada, e concluir, baseados somente os valores verificados in loco, e concluir que o problema esteja no motor. Em 90% dos casos, o problema está no componente em que este motor está operando. Por exemplo, um sistema motriz composto principalmente de motor e bomba, as perdas no sistema, como um todo, pode estar na bomba e não no motor. O motor entrega ao sistema o que é solicitado, mas se esta bomba estiver operando fora da curva, sem manutenção, com anel de selagem gasto, por exemplo, a perda no sistema continuará acontecendo mesmo substituindo o motor de comercial comum por motor de alta eficiência. A perda de eficiência está na bomba não no motor. É preciso analisar o sistema motriz como um todo.

It is important to remember that it is not enough to replace common motors with high efficiency motors, this exchange alone is not a guarantee of energy efficiency improvements in the driving systems operating in an industrial process. It is necessary to understand which engine system is motor plus load driven. It is not possible to analyze the motor in isolation and conclude, based only on the values checked in loco, and to conclude that the problem is in the motor. In 90% of cases, the problem is in the component where this engine is operating. For example, a motor system composed mainly of motor and pump, losses in the system as a whole may be in the pump and not in the motor. The engine delivers what is required to the system, but if this pump is operating off-the-curve, maintenance-free, with a sealing ring worn, for example, the loss in the system will continue to occur even by replacing the common commercial motor with high efficiency motor . The loss of efficiency lies in the pump, not in the engine. It is necessary to analyze the motor system as a whole.

I am electrician

I’m glad that developers have figured out the power factor correction for electric motors. I’ve been having a problem with that in my motor for quite some time. Minimizing the idling in my motor seems like an excellent way to correct the issue. Now I can install capacitors in my motor’s AC circuit to fix it. Thanks for the information!

I must congratulate the author for his courage to support oversized motors. In simple terms it tells you to allow higher values of starting current, if your system can, instead of sticking to heritage values of say 600% even for the smallest motor on the system. I remember, about 30 years back a similar sentiment was expressed at CIGRE.

Useful piece of information

Great article most facility energy mangers don’t give this issue the attention it deserves.

good article

good web site