8 Obligatory Checks

The transformer should be powered up only after checking the following items: name plate ratings, parallel operation, connections: cables, busbars, tap change connections, grounding connection, thermal protective device, impurities removal and insulation resistance test.

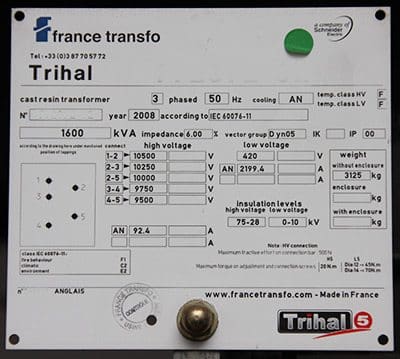

1st Check (name plate ratings)

1st Check (name plate ratings)

Make sure the name plate ratings are in accordance with the ratings foreseen for the place of installation.

2nd Check (parallel operation)

2nd Check (parallel operation)

When transformers are to be operated in parallel, make sure they are connected with the right polarity. If there is only one transformer or more of them, but not operated in parallel, just skip to the next check.

Learn more about principles of transformers in parallel connection.

3rd Check (connections: cables, bus bars)

3rd Check (connections: cables, bus bars)

Make sure all connections to cables or bus bars are properly connected and well positioned.

4th Check (tap change connections)

4th Check (tap change connections)

Make sure that all connections at the tap change panel are firmly tightened and at the same position in the three phases.

5th Check (grounding connection)

5th Check (grounding connection)

Make sure the grounding mesh is correctly connected to the bolt provided for this purpose.

In addition, make sure the grounding mesh has been correctly executed at the right place foreseen in the project and shown in the drawing.

6th Check (thermal protective device)

6th Check (thermal protective device)

In case of transformers fitted with a thermal protective device, check the connections of the circuit, making sure that the voltage is in accordance and that the alarm and shut-off contacts are connected to their corresponding loops.

7th Check (impurities removal)

7th Check (impurities removal)

Make sure there are no materials, equipment or any other impurities laid on the transformer, between the coils or obstructing the ventilation in the cooling channels.

8th Check (insulation resistance test)

8th Check (insulation resistance test)

It is always recommendable to check the insulation resistance by making measurements between the LV and HV windings and from the windings to the ground.

ONLY after these checks are made, the transformer can be connected to the system.

Voltage shall be applied while the transformer is set to no load, and such voltage shall be measured at the secondary winding to check for the corresponding output ratings. Operations under voltages other than the rated one can cause saturation significant loss increase, which could lead to over-heating and noise above the standard levels.

The load should be applied progressively until the rated power .

References:

- Schneider Electric – Trihal Catalogue

- Instruction Manual For Dry-type Transformers – WEG

Kindly , I have a question about the difference between Cast resin and Cast impregnated dry type transformers .

Similar checks must also be done for oil type transformers.

SIR, IF ONE NO OF LV COIL SHOWS BURN AND POWER FAILS, CAN BE REPLACED ONLY LV COIL AFTER PROPER TEST. It IS OF 250 KVA DRY TYPE TRFM. Sir PLZ REPLY WITH COST

Good Day.

Need Help

our 500kva 220V-440V step-up dry-type transformer is to supply a 145kW Emulsifier Machine.

The problem is, when the machine starts, the voltage drops (220V drops to 210V ; 440V drops to 298V)

Current ramps up to 2870Amps (primary side) and 1116Amps (secondary side – 440V).

Due to this, the 1200Amps 220V MCCB trips off.

(If we set the long-time trip setting of the breaker from 0.5 to 4 seconds (over exceeding the 3sec setting of Wye-Delta Starter) the breaker wont trip and the running current drops to normal FLA, as well as the voltage on each side)

What seems to be the problem?Is the transformer undersized for the 145kW load considering the high starting current?

Please share me some of your thoughts

Thank you

Hi.

I would like to ask one question about the bus bars of dry type transformer.

I have found the difference of the size of bus bars on winding, palm and extension bus bars.

Why is the size of bus bars on winding is difference with the palm and also with the extension bus bars? is it because the heat, losses or any other reasons?

As for oil type transformers, the size of bus bars in the tank differ from outside the tank because of the density of oil (in the tank) and density of air (outside the tank).

it would be much appreciated if you share the answer to me and to other viewers.

Have a nice day!

Hi this is very important tool for A class contractors,

Sir,Your all articles are very useful, interesting and informative.Can you post a article on Insulation Class?If you will post it,I feel very glad.

Thank you.

Thanks gor this usefull information. Can you please post about transformer percentage impedance in simple words.

I´d add as well to check the lenght of the bolts that connects the primary side. If they are too short, an arc can occur between the end of the bolt and the surface where the bolt should reach to. This arc produces burned área in the connection surface, that with the time results in high resistance that breaks the connection by heat increase.

Hi everyone

can u please post something about insulation resistance..thanks

In sub zero temperature, further precaution in form of pre heating is required, as per the startup instructions provided by specific Transformer manufacturer. Most of the dry type transformers cannot start from the cold.

Hi!

Thank for this article, can you please post something about the maintenance works needed for dry-type transformers.

Merry Christmas and a Happy New Year!

Yan