Motor Starter

While the lighting control system previously discussed is useful to explain basic PLC operation, a more practical, and only slightly more complex, application is start-stop control of an AC motor. Before examining the PLC program, first consider a hard-wired approach.

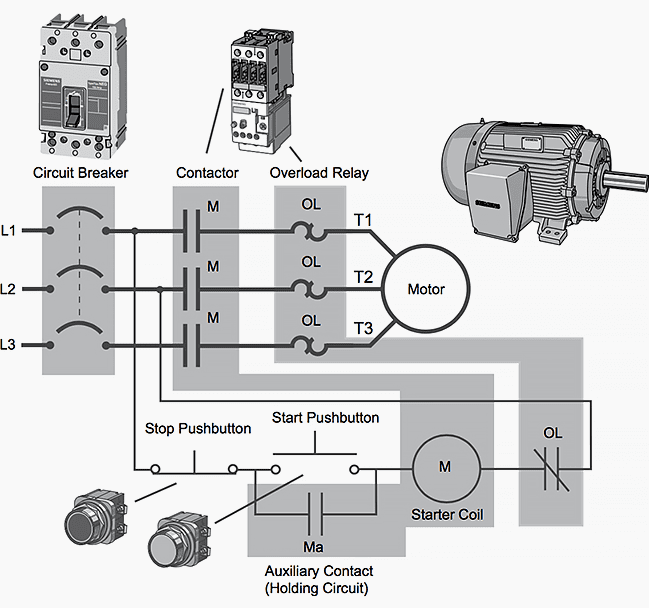

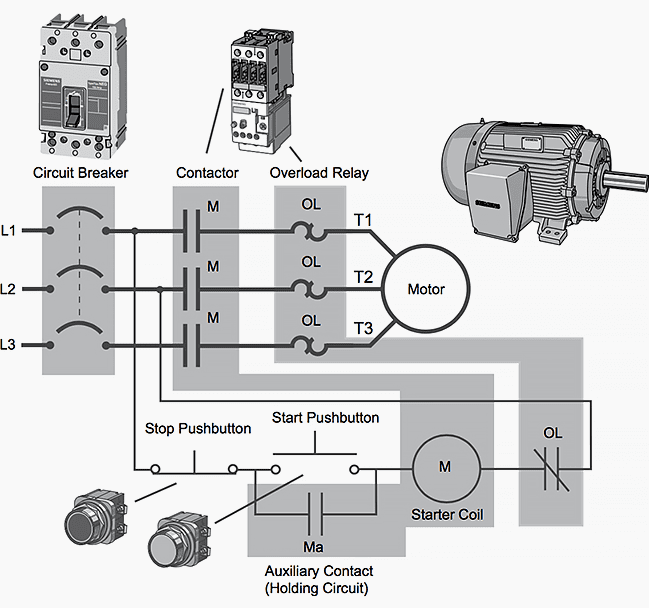

The following line diagram illustrates how a normally open and a normally closed pushbutton might be connected to control a three-phase AC motor.

In this example, a motor starter coil (M) is wired in series with a normally open, momentary Start pushbutton, a normally closed, momentary Stop pushbutton, and normally closed overload relay (OL) contacts.

Momentarily pressing the Start pushbutton completes the path for current flow and energizes the motor starter (M). This closes the associated M and Ma (auxiliary contact located in the motor starter) contacts.

The motor will run until the normally closed Stop button is pressed, unless the overload relay (OL) contacts open. When the Stop button is pressed, the path for current flow is interrupted, opening the associated M and Ma contacts, and the motor stops.

This is how hard-wired motor starter functions. Now, let’s discuss a little bit about PLC running the same //

- PLC and motor control application

- PLC program operation

- Adding Run and Stop indicator lights to program

- Adding a limit switch to program

- Further expansion of a PLC program

PLC and motor control application

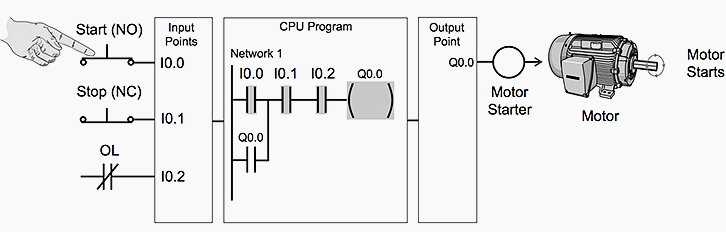

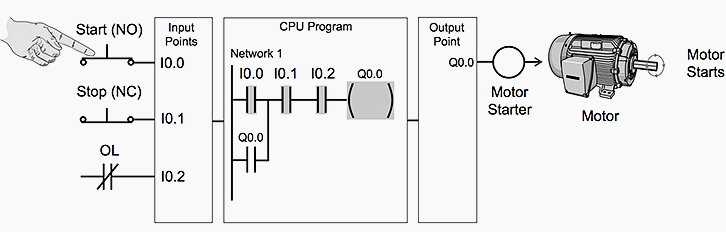

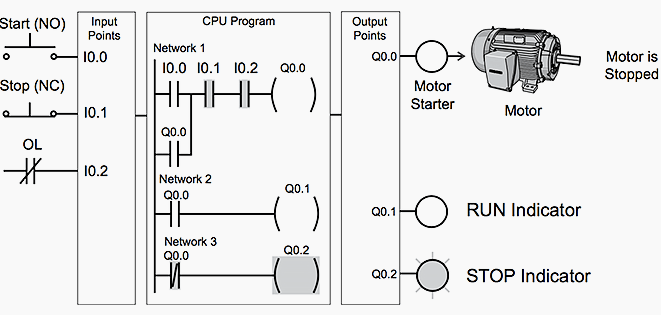

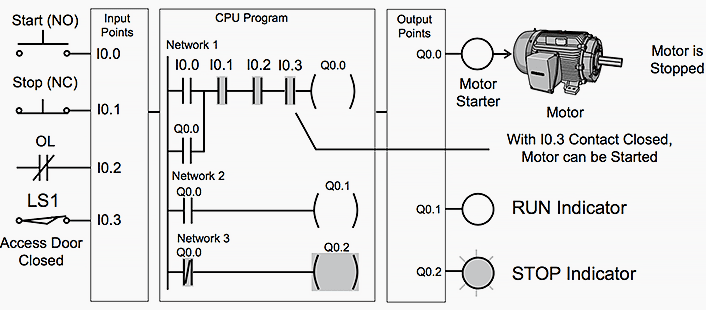

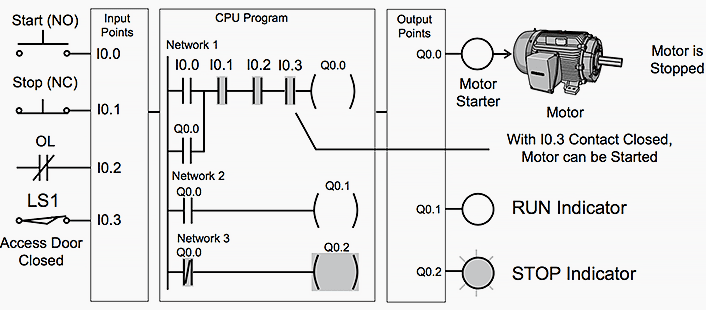

This motor control application can also be accomplished with a PLC. In the following example, a normally open Start pushbutton is wired to the first input (I0.0), a normally closed Stop pushbutton is wired to the second input (I0.1), and normally closed overload relay contacts (part of the motor starter) are connected to the third input (I0.2).

These inputs are used to control normally open contacts in a line of ladder logic programmed into the PLC.

Initially, I0.1 status bit is a logic 1 because the normally closed (NC) Stop Pushbutton is closed. I0.2 status bit is a logic 1 because the normally closed (NC) overload relay (OL) contacts are closed. I0.0 status bit is a logic 0, however, because the normally open Start pushbutton has not been pressed.

Normally open output Q0.0 contact is also programmed on Network as a sealing contact. With this simple network, energizing output coil Q0.0 is required to turn on the motor.

PLC program operation

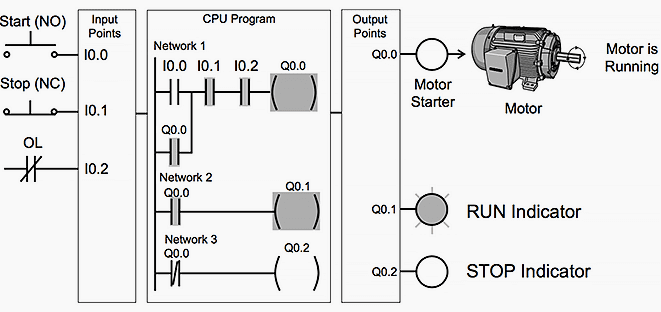

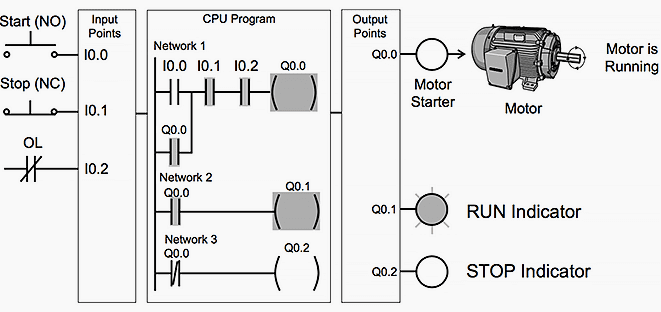

When the Start pushbutton is pressed, the CPU receives a logic from input I0.0. This causes the I0.0 contact to close. All three inputs are now a logic . The CPU sends a logic to output Q0.0. The motor starter is energized and the motor starts.

The output status bit for Q0.0 is now a . On the next scan, when normally open contact Q0.0 is solved, the contact will close and output Q0.0 will stay on even if the Start pushbutton is released.

When the Stop pushbutton is pressed: input I0.0 turns off, the I0.0 contact opens, output coil Q0.0 de-energizes, and the motor turns off.

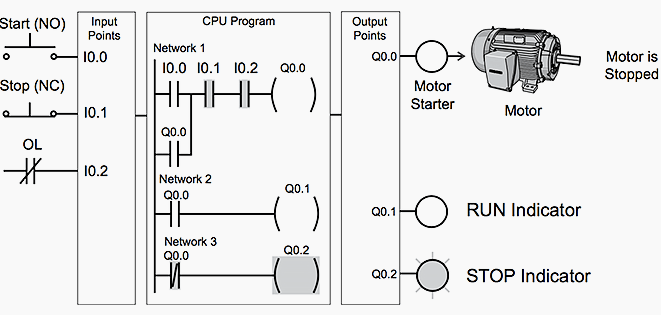

Adding Run and Stop indicator lights

The application can be easily expanded to include indicator lights for run and stop conditions. In this example, a RUN indicator light is connected to output Q0. and a STOP indicator light is connected to output Q0.2.

The ladder logic for this application includes normally open Q0.0 contact connected on Network 2 to output coil Q0. and normally closed Q0.0 contact connected on Network 3 to output coil Q0.2. When Q0.0 is off, the normally open Q0.0 contact on Network 2 is open and the RUN indicator off. At the same time, the normally closed Q0.0 contact is closed and the STOP indicator is on.

When the Start button is pressed, the PLC starts the motor. Output Q0.0 is now on. Normally open Q0.0 contact on Network 2 is now closed and the RUN indicator is on. At the same time, the normally closed Q0.0 contact on Network 3 is open and the STOP indicator light connected to output Q0.2 is off.

Adding a limit switch

The application can be further expanded by adding a limit switch. The limit switch could be used in this application for a variety of functions. For example, the limit switch could be used to stop the motor or prevent the motor from being started.

In this example, the limit switch is associated with an access door to the motor or its associated equipment. The limit switch is connected to input I0.3 and controls a normally open contact in the program. If the access door is open, limit switch LS is open and normally open contact I0.3 is also open. This prevents the motor from starting.

When the access door is closed, limit switch LS is closed and normally open contact I0.3 is also closed. This allows the motor to start when the Start pushbutton is pressed.

Further expansion of a PLC program

The PLC program can be further expanded to accommodate a wide variety of commercial and industrial applications.

As needed, expansion modules can be added to further increase the I/O capability. The applications are only limited by the number of I/Os and amount of memory available for the PLC.

Reference // The basics of PLCs by SIEMENS

Thank you. The most clear and straightforward explanation of this hardwire/plc comparison.

Thank you!

thank you sir

How to program in PLC running electric motor from 2 source voltage 1. From main source then after running within 30-60 second it will continue running from the 2nd source generator continuously 24/7

Thank you.

Khalid Morales

I believe you are wrong here. Ol isn’t an input since it goes to the contacts and the contact is an output, the ol should go back to ground. Btw your main physical diagram isn’t grounded. You have the PB running from the first phase leg then ol going to the second phase leg, where is your ground? Also you show no contacts in your diagrams. Motor starters have contacts

Pretty sure the ol is not an input. The reason I say this is because if you wire it physically the ol goes back to ground through the contacts..and the contact is an output on the plc..and you didn’t do anything with the ol or explain why it’s an input, it’s just there as an input

We need help for our project

Our project is 3phase induction motor protection and electrical braking

Now we think we done with plc

So give me program for it

Protection:earthfault using RCCB, thermal relay,over current,single phasing,

Thanks

A complete and elegant overview of this everyday tool of the electrical engineer. Great work!

hi Edvard

I was wondering of you can help with the best and basic way of estimating a price for an MCC and PLC just for insurance purposes

Thank you!

Wonderfully explained. Keep going

Edvard,

I wanted to thank you for such a great technical article, this information has given me a boarder ensite on how PLC controls work in conjunction with modern control circuits.

Thank you,

Dear sir,

I am greatly thanked you for your fullest commitment to develop technical knowledge of people in global by sharing more electrical articles.This help us easier to understand.its like a user manual.application oriented electrical articles.its gives good motivation too.

Thanks you sir

Dear Sir,

Thanks alot for your great technical information .

I work in elevator field also am intrested to know more about PLC and its applications in elevator industry .

I would like tro know if there is system control that can be used of Plc .

I used to work with Siemens logo PLC.

Best regard,

Kamran

thank you Edvard Csanyi

Thanks a lot.