Substation equipment renewal

An increasing number of substations globally are aging, while the construction of new ones is hindered by competitive limitations, rigorous environmental rules, and community acceptance issues. Simultaneously, the demand for electricity is consistently escalating, resulting in increased short circuit levels due to the integration of additional generation to meet this increased need.

Public and private electrical utilities are facing challenges in optimizing the use of existing substation equipment while experiencing increased demands to manage development, operational, and maintenance expenses. Simultaneously, they must address the challenge of refurbishing outdated substations to ensure their safe and reliable operation.

Consequently, the electrical sector seeks guidelines for assessing the suitability and condition of existing substation equipment, as well as approaches to enhance equipment renewal processes.

This article discusses only air-insulated substations. Gas-insulated substations are omitted from this discussion simply because the renewal of such equipment is much different.

What are the possible solutions?

You can pick from a variety of options. A lot of things might have different effects, but the first thing that usually comes into play is the money. Parameters like voltage level or maximum permitted risk are part of the business strategy, which is the second decision element.

Development and introduction of new technology is an also essential aspect. Compatibility between old and new equipment has become a severe issue in terms of investment costs.

Another important factor is the condition of the substation equipment. Finally, when it comes to upgrading the substation, the inherited manner of working is a major factor.

1. Just sit tight for the time being and do nothing

When it comes to a substation equipment with modest investment costs and minimal implications for a malfunction, a corrective maintenance strategy will only replace or repair it if it fails.

Some utilities are expressing dissatisfaction with the growing demand for cost savings, which forces them to prioritize investments in new or upgraded equipment. Next, the business will assess the state of the substation and make a decision based on that assessment. Systems with lower voltages will mostly utilize this method.

The method will only be affected by catastrophic failures of specific types of equipment. Maintenance and operation costs will be minimal, but failure could result in astronomical operational costs.

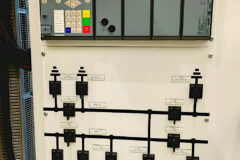

Figure 1 – Substation hazard due to circuit breaker failure

2. Carry out scheduled maintenance on existing substation equipment

All of the available maintenance choices fall under the umbrella of preventive maintenance, which encompasses any action taken with the intention of:

- Find out when equipment is going to start to malfunction.

- Before it affects the equipment’s function, find a failure.

- Prevent equipment failure by replacing or repairing it before it happens.

An action and the frequency with which it is to be performed are two distinguishable qualities. Deterioration and failure rates, operational strategy, activity expense, and penalty for asset failure can all influence how often preventive maintenance is performed.

Using asset failure data to build decision models for when to inspect, repair, or replace an asset might be helpful.

On the other hand, condition-based maintenance has been on the rise for a while now, replacing time-based maintenance. With condition-based maintenance, money can be directed toward those pieces of equipment or parts that need replacement or repair right away. Reducing needless repair/replacement expenses and substation operation interruptions, maintenance operations are performed only when they are truly necessary.

The technical condition of the equipment is the primary factor in condition based maintenance. To find the technical state as accurately as possible, this method takes into account all important parameters. This is why comprehensive data should be accessible through various monitoring and diagnostic tools.

Maintenance Management Of Electrical Equipment (Condition Monitoring Based)

Before deciding on an appropriate maintenance plan, it is crucial to analyze the equipment’s behavior under fault conditions. The most important characteristic can be used to qualify condition based maintenance.

Two other types can be identified:

Subtype #1: Think about the equipment’s condition, how important it is to the grid, and how risky it is to fail. There are a lot of factors to think about in this scenario, such as:

- The substation’s accessibility

- The equipment’s failure rate

- The layout of the substation

- Power interruptions

- The type of customers

- The social effect

Subtype #2: A mix of the equipment’s condition, the cost of the works, and the financial impact in the event of a supply interruption to customers.

Predictive maintenance is an additional method towards maintenance. With the same goals as condition-based maintenance, it seeks to identify and prevent future maintenance issues. Lastly, another choice is to enhance the maintenance plan to prolong the life of the equipment, delaying its renewal.

This strategy could be chosen for various reasons:

- There are other priorities to renew.

- It requires an unacceptable down time for operation.

- In order to save money and minimize downtime, etc., utilities prefer to wait for the substation to be partially or completely renewed.

Here, capital expenditures are low, but maintenance costs will skyrocket.

The utilities can’t do their own equipment condition assessments, staff training for inspections, or data analysis for maintenance choices without outsourcing.

Audit report for 40 years old 3.3kV and 11kV switchboards (incl. condition photos)

3. Be smart when replacing substation equipment

When the problem is located on a single piece of equipment:

When any substation equipment, such as circuit breaker, CTs, VTs, switch disconnector, or protection & control equipment fails, the owner has to replace it quickly, in order to restore supply. Minimizing downtime and avoiding blackout are more critical than costs in this situation.

In order to replace a whole generation of equipment (due to obsolescence, malfunctioning generation, etc.), the utility’s strategy could incorporate a renewal plan. In order to lower the associated operating and maintenance costs, the business can plan the supply, installation, and commissioning:

- Utilising existing shut-downs.

- Doing other maintenance works at the same time.

- Depending on the bus configuration (circuit breaker and a half, bypass switch) it is possible to minimise considerably the downtime.

Before deciding how to proceed, it is necessary to assess the current state of the equipment and evaluate its overall significance to the network, taking into account factors such as the impact of equipment failure on supply reliability.

In order to determine the best order in which to perform maintenance on each device or to choose which pieces of equipment to replace, it is necessary to combine and analyze both sets of data.

The life of a power substation project: Design, construction, erection and commissioning

4. Partial renewal of the substation

A few instances of this method in action are:

- Renewal of secondary systems (the primary equipment life expectancy is about double than secondary system).

- Migration to digital control systems.

- Renewal of auxiliary systems.

To avoid any conflicts and make sure the substation equipment is properly integrated with other site activities, careful preparation is required for the delivery, installation, and commissioning of the equipment. There are a lot of manageable task packages that might be created from the whole project. The benefit of utilizing existing shutdowns is the reduction of downtime.

Since a complete substation renewal involves gradual modifications and a uniform solution is difficult to achieve, this option may end up costing more than the others.

Substation design choices and reasons for a new modern vs retrofit and upgrade an old one

5. Total renewal of the substation

The decision to completely renew the substation may be forced by its condition of obsolescence. Two primary approaches are available:

- Dismantle and reassemble everything.

- To make gradual adjustments, such as renewing one bay or a group of bays while leaving the others unchanged.

The first one provides a uniform solution, less expensive than the progressive change since there is no specific cohabitation interface to be solved and a single installation and commissioning process is required. The second one is the most common and requires setting up a migration strategy, defining the different steps to be followed to match the objectives.

Here are some benefits of this approach:

- Improvements to annual spending plans.

- Quickly installing each bay while ensuring that the voltage in the other bays remains constant.

This could be done in two different ways:

- Increase the capacity of the equipment. This solution refers to replacement of circuit breakers, conductors, transformers, etc.

- Increase the nominal voltage of the substation. In this case conductors, bus bar, relays, control buildings remain, but other pieces of equipment have to be replaced, e.g. surge arresters, power and measuring transformers and switches.

References:

- Fundamentals of Modern Electrical Substations by Boris Shvartsberg, Ph.D., P.E., P.M.P.

- Guidelines to an optimized approach to the renewal of existing air insulated substations – Cigre

- The substation by Mladen Kezunovic

- Transmission and Substation Design and Operation – Technical Papers – TSDOS

- GIS substations by H. J. Koch

- Gas Density Monitoring System (GDM) by Siemens

- A Study on The Development of a Novel Coupler for GIS PD Detection by Jaegu Choi, Kwanghwa Kim, and Iksoo Kim

It’s very simple,clear and faster source of electrical knowledge

Thank you sir

Thank you, Dessie. That’s exactly the aim of this article!