Busbar trunking system material

These two materials (aluminium and copper) are both physically and economically viable for use as conductors in power busbar trunking systems (BTS). Some manufacturers of busbar trunking systems offer a product with copper busbars and others offer a product with aluminium conductors.

Increasingly almost all major manufacturers are offering both products, leaving the choice to the customer.

Traditionally, for example, in the UK in copper conductors have predominated both for busbar trunking system and cable. In other markets, the USA and mainland Europe for example, aluminium has had the greater role.

The decisions leading to the choice of material would have been influenced by the availability of the raw material and its cost, rather by the physical properties of the respective materials.

Another factor would have been the ratio between the use of cable and the use of BTS in the market. In many countries, it can be shown that BTS has increased its share of the market relative to cable, to some extent due the increasing amounts of power required in buildings, in particular for automated industrial units and high-rise commercial centres.

Some of the factors affecting the choice of busbar material are subject to change, in particular the cost of raw material, and the facts needed to allow an informed choice are summarised below.

Factors affecting the choice of busbar material:

1. Performance

The performance of a busbar trunking system (BTS) using either aluminium or copper busbars will be the same for any given specification. Performance is dictated by compliance with the current national standard BS EN 61439-6 which is identical with international standards EN 61439-6 and IEC 61439-6.

The performance requirements consist of:

- Dielectric properties (power frequency and impulse voltage withstand)

- Fire resistance (where applicable)

- Impedance characteristics (R, X, Z)

- Ingress protection (IP rating)

- Mechanical strength, crush resistance

- Short-circuit withstand

- Temperature rise

- Thermal cycling (tap-off units)

- Voltage drop characteristics

Go back to factors affecting the choice of busbar material ↑

2. Physical Properties

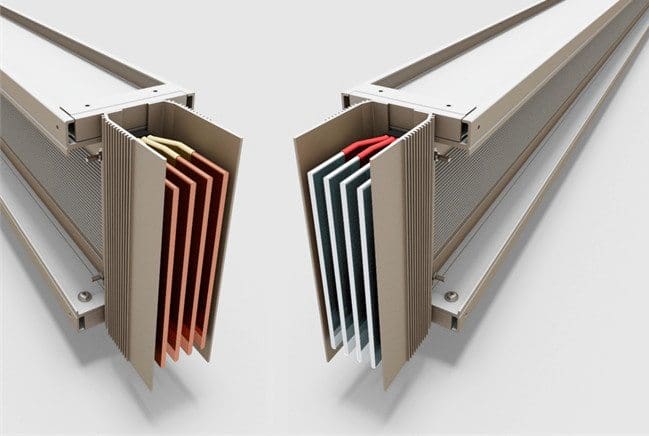

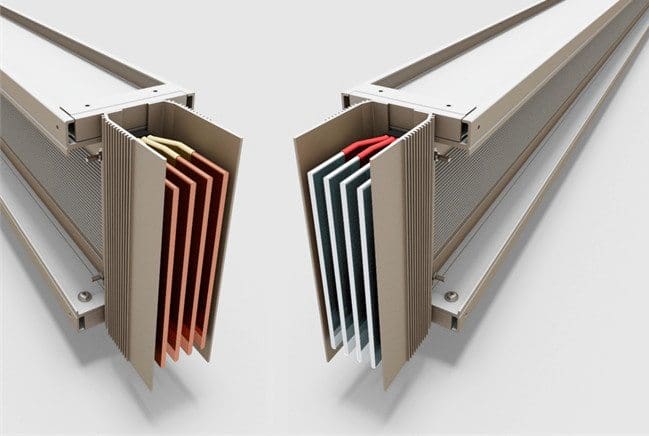

Aluminium has a lower density than copper and copper has a higher conductivity. The effect of these differences on busbar trunking unit (BTU) design is explained, taking high-power, low-impedance BTS (also known as ‘compact’ or ‘sandwich-type’) as the basis.

In many cases the conductors of a busbar trunking system are totally shielded by the equipotential metal casing of the system.

In the case of sandwich type construction the conductors are closely packed together and the induced magnetic fields cancel one another to a large extent, resulting in an extremely low external magnetic field.

The material of the conductors in a BTS (copper or aluminium) has negligible effect on the magnetic field.

Go back to factors affecting the choice of busbar material ↑

3. Weight

The lower density of the material means aluminium busbar BTS will be lighter for a given current rating.The lower density is offset to some extent since the lower conductivity of aluminium means that the size of the busbars will be greater than copper for a given current rating.

The busbar weight is only a proportion of the total weight of a BTU which includes the case, which may be of aluminium or steel, plus the insulation and jointing means.

However it can be shown that, on average, a busbar trunking unit with aluminium busbars will be 30% lighter than a BTU of the same current rating with copper busbars.

Go back to factors affecting the choice of busbar material ↑

4. Dimensions

Size does matter sometimes! To accommodate the larger busbar sizes needed with aluminium, the overall dimensions of the BTS are generally greater than for copper busbar BTS.Typically the overall cross-sectional area (c.s.a) of a straight-length BTU with aluminium busbars will be 10 – 20% greater than a length of the same current rated BTU with copper busbars.

Note that the size of the conductors in the busbar trunking is designed to meet the performance characteristics of the standard. It is not necessary or helpful for conductor sizes to appear in the user specification.

Go back to factors affecting the choice of busbar material ↑

5. Voltage drop

The voltage drop along a busbar trunking system run is dependent on the current flowing and the impedance (resistance and reactance) of the busbars.

Due to the higher conductivity of copper, offset to some extent by the larger busbar c.s.a in aluminium, the voltage drop per unit length with copper busbars will be on average some 25% lower than with aluminium of the same current rating.

Go back to factors affecting the choice of busbar material ↑

6. Power loss

A few years ago this might not even have been a consideration, but now it may enter into the equation, since it will be a factor, however small, in the overall operating efficiency of an installation. Power loss figures can be made available from the data taken during BTS performance testing.

Since power loss is largely proportional to the electrical resistance of the busbars it will be typically 25% lower with copper busbar trunking system than with aluminium busbar trunking system of the same current rating.

This however needs to be put in perspective. For example, an 800 A 3-phase trunking run can transmit up to 500 kW of load power, the power loss in 50 m of the trunking is in the order of 8 kW i.e. 98.4 % transmission efficiency.

Go back to factors affecting the choice of busbar material ↑

Reference // Guide to Low Voltage Busbar Trunking Systems Verified to BS EN 61439-6 by Beama

How to calculate BB current density, what is the formula?

What are the heat dissipation and temperatures in an enclosed cupboard having dimensions of 800 mm (W)x800mm(D) x 2.8 M high , with 2x1600A TPN, IP65 Aluminum bus bar trunking risers with ampere loads of 50%, 75% and 100% of the 2x1600A tpn Alum. Bus bars.

Good insight

You are a great person :)