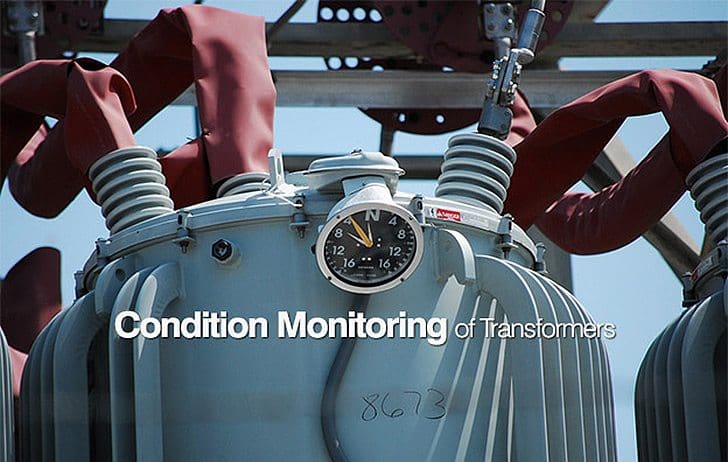

Detecting early signs of deterioration

It is possible to provide transformers with measuring devices to detect early signs of degradation in various components and provide warning to the operator in order to avoid a lengthy and expensive outage due to failure.

The technique, which can be applied to other plant as well as transformers, is called condition monitoring, as the intent is to provide the operator with regular information on the condition of the transformer.

Such techniques are an enhancement to, but are not a replacement for, the protection applied to a transformer.

The extent to which condition monitoring is applied to transformers on a system will depend on many factors, amongst which will be the policy of the asset owner, the suitability of the design (existing transformers may require modifications involving a period out of service – this may be costly and not justified), the importance of the asset to system operation, and the general record of reliability.

Therefore, it should not be expected that all transformers would be, or need to be, so fitted.

A typical condition monitoring system for an oil immersed transformer is capable of monitoring the condition of various transformer components (bushings, tank, tap changer, coolers and conservators) as shown in Table 1 below.

There can be some overlap with the measurements available from a digital/numerical relay.

By the use of software to store and perform trend analysis of the measured data, the operator can be presented with information on the state of health of the transformer, and alarms raised when measured values exceed appropriate limits. This will normally provide the operator with early warning of degradation within one or more components of the transformer, enabling maintenance to be scheduled to correct the problem prior to failure occurring.

The maintenance can obviously be planned to suit system conditions, provided the rate of degradation is not excessive.

Reference: Network Protection & Automation Guide – Areva

Hi,

Im interested in monitoring

Tap changes

Bushings

The Active part

Cooling

The question is , what instruments do you use to do this. and it must have 4-20mA outputs so that I can monitor it, I’m also going to measure structural vibration as well as cooling fans bearings & winding vibration with fibr optice accelerometers

Maintenance concepts and condition monitoring ensure efficient processes.

You can finde more infos hier:

http://www.industry.siemens.com/services/global/en/portfolio/plant-condition/Pages/index.aspx

EEP is very useful tool for electrical engineers.