Contactors for DOL starters

Contactors for use in direct on line starters (DOL) are normally selected by their AC3 rating, that is the switching on of a cage type induction motor and switching off the supply to the motor after the motor has run up to full speed.

The other most common utilisation categories are AC4, the switching on and off of a cage type induction motor before it has run up to full speed, sometimes termed ‘inching’ or ‘jogging’ the drive, and category AC2, the switching of the stator supply to a wound rotor motor where the starter circuit automatically inserts resistance into the rotor circuit for each start.

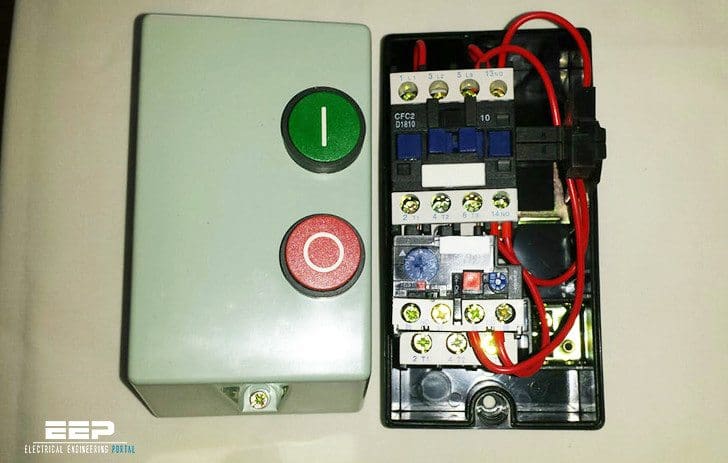

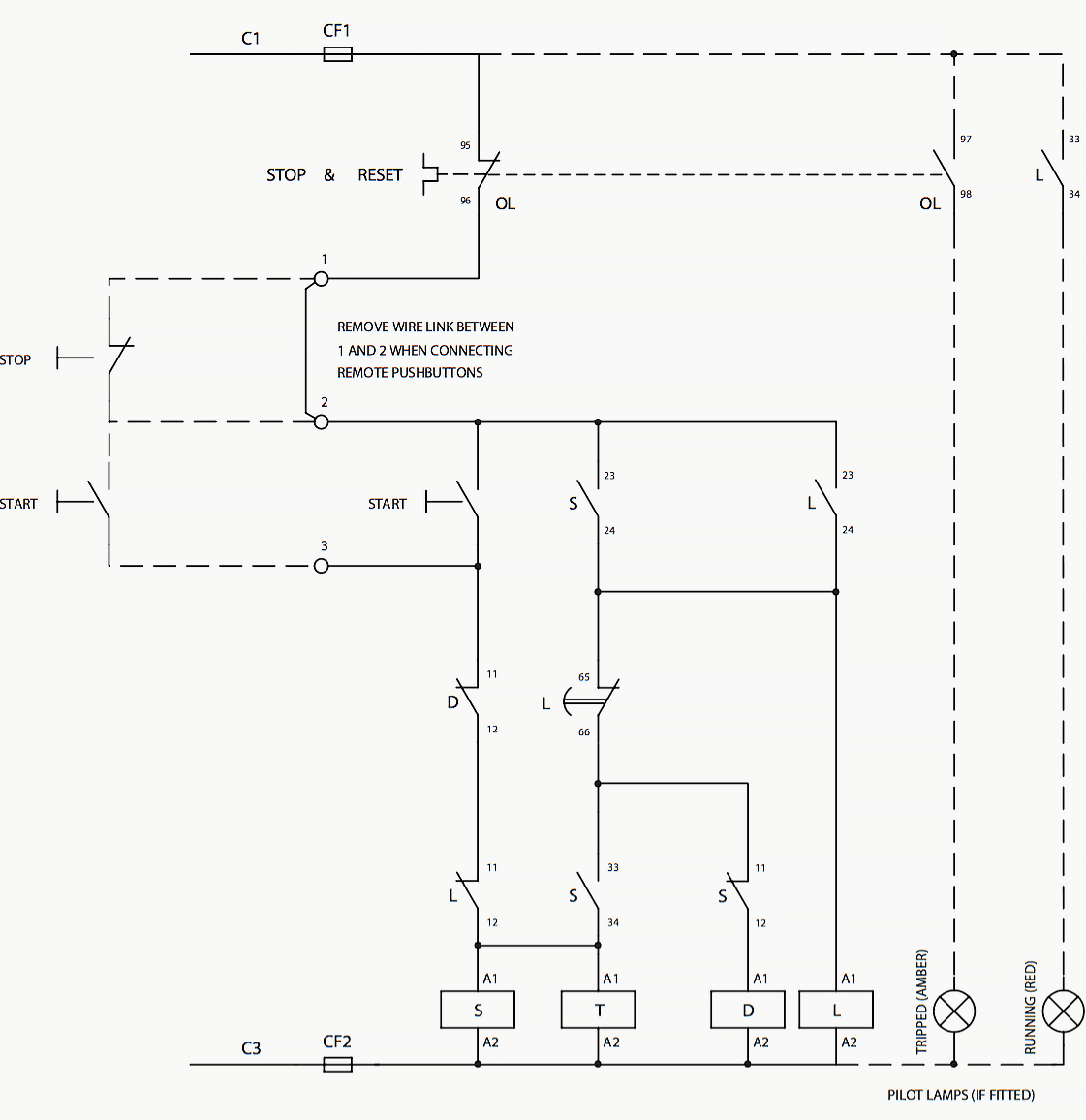

Figure 1 shows a star-delta starter.

Catalogued ratings //

The catalogued ratings are published on the basis of known service conditions, typically //

Rating #1 – Ambient temperature outside the starter enclosure between -5° and 35°C average (with a maximum not exceeding 40°C).

Rating #2 – Rate of operation to be specified by the manufacturer, typically 120 starts per hour.

Rating #3 – The duty cycle or utilisation category – see Table 1 for typical values of current to be switched during type testing and in service, e.g. is the starter a reversing type which must reverse a motor which is already run up to speed, or does the reversing only occur after allowing the motor to come to rest? In the latter case only AC3 rated contactors could be used.

Rating #4 – The acceleration time of the drive, the ability of the contactor to carry the starting current, must be considered. AC3 rated contactors are able to carry eight times rated current for a minimum of 10 s (this applies to ratings of up to 630 A. Above this the value is six times rated current).

Rating #5 – Any special contact life requirement.

Rating #6 – The type of short-circuit protective device to be installed in series with the supply to the starter, and the classification of type of protection to be obtained.

Rating #7 – Any special coordination requirement, e.g. are there any residual current devices, which on detecting a fault condition may attempt to open the contactor on a current in excess of its breaking capacity.

Rating #8 – Any special requirement to attach cables of other than copper cored, PVC or rubber insulated types to the contactor terminals, e.g. the use of some types of high temperature insulation such as XLPE allows the cable to run much hotter than the manufacture expected.

The normal practice is to design for use with 70°C cable so the possible economies of using XLPE may be not be exploited as the core temperature may be as high as 250°C, consequently the cabling would act as a heat source, not a heat sink.

Table 1 – Contactor utilisation categories

| Utilisation category | Current as multiples of operational current (Ie) | |||

| Normal operation | Proving operation | |||

| make | break | make | break | |

| AC1 – Non-inductive or slightly inductive loads such as furnaces and heating loads | 1 | 1 | 1.5 | 1.5 |

| AC2 – Starting of slip ring motors. Plugging with rotor resistance in circuit | 2.5 | 2.5 | 4 | 4 |

| AC3 – Starting of cage motors, switching of motors during running | 6 | 1* | 10 | 8 |

| AC4 – Starting of cage motors, plugging inching | 6 | 6 | 12 | 10 |

All tests carried out at supply voltage for normal operation except as indicated below and at 105% voltage for proving operations. For full details and power factors, etc. refer to specification IEC 947/BS EN60947.

* At 17% supply voltage.

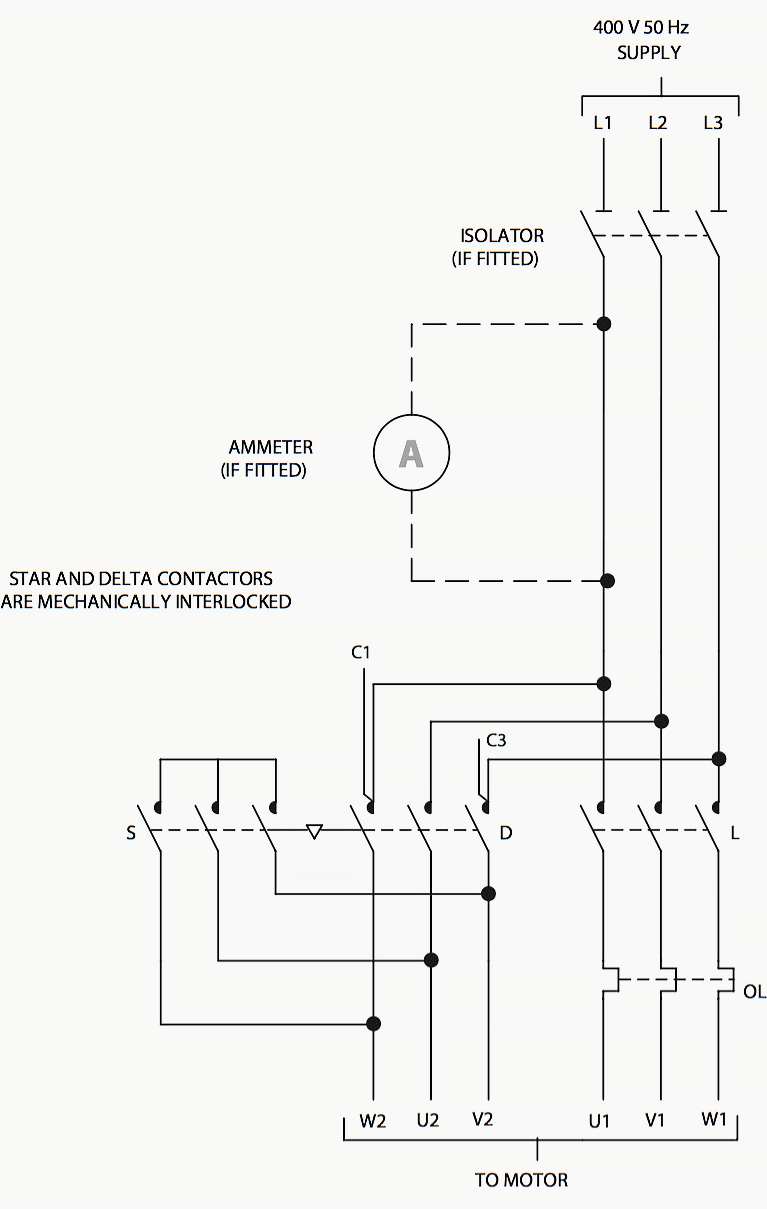

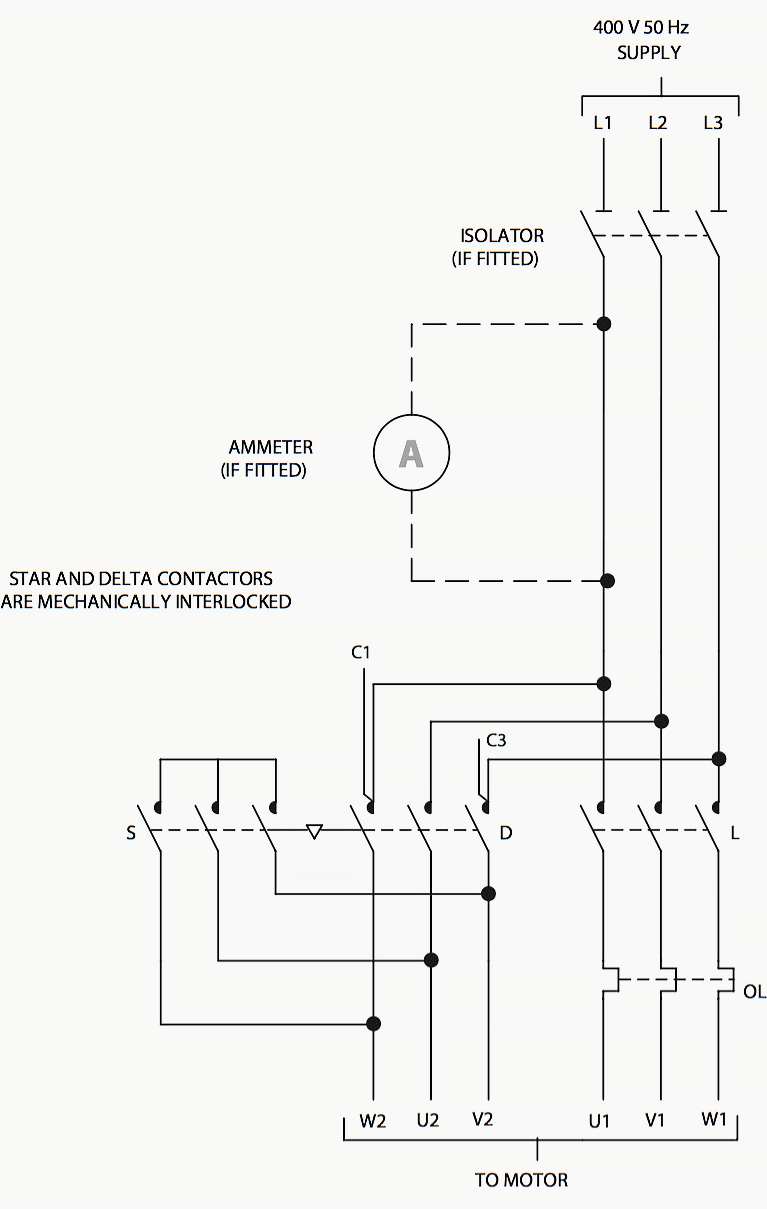

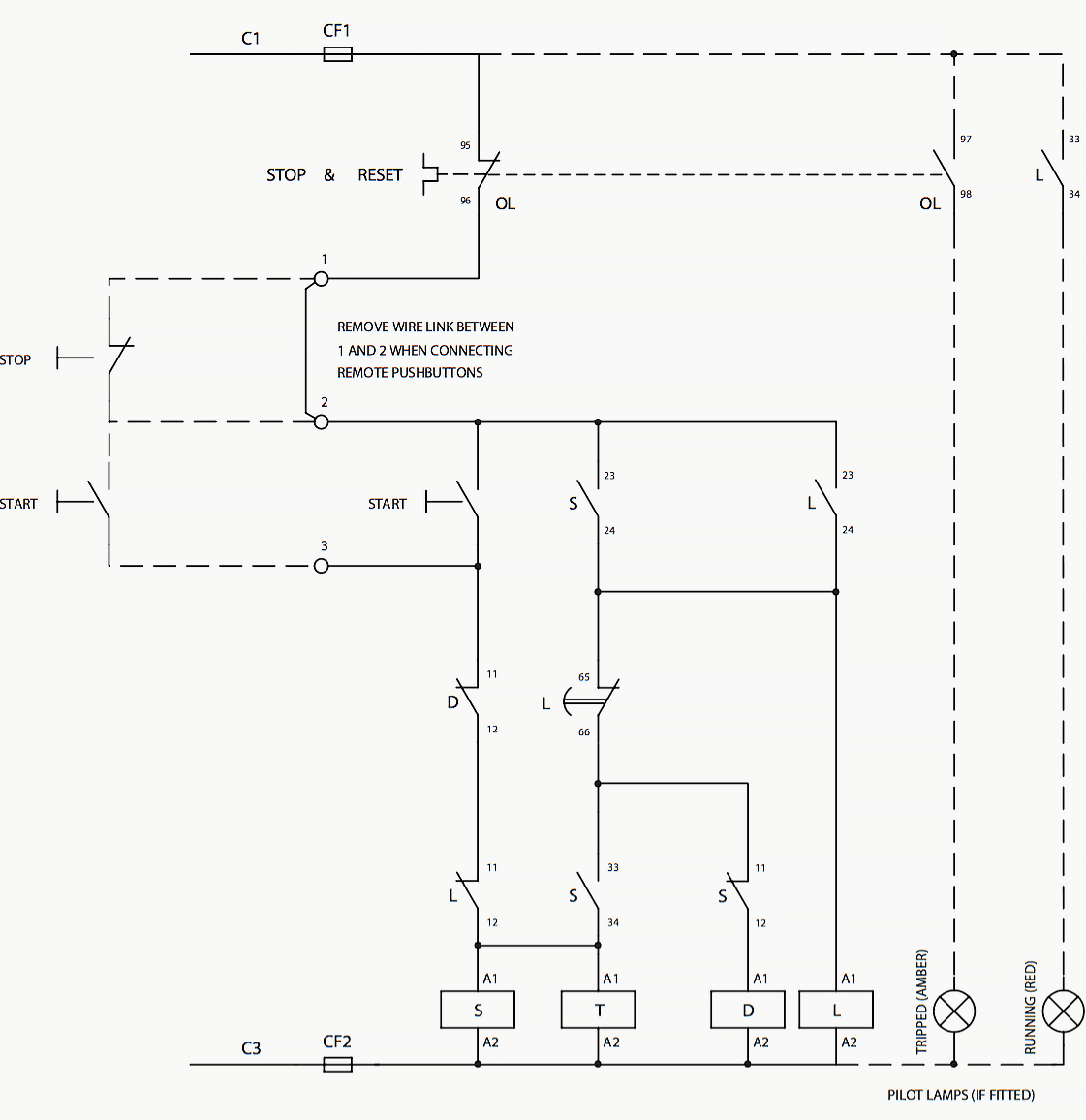

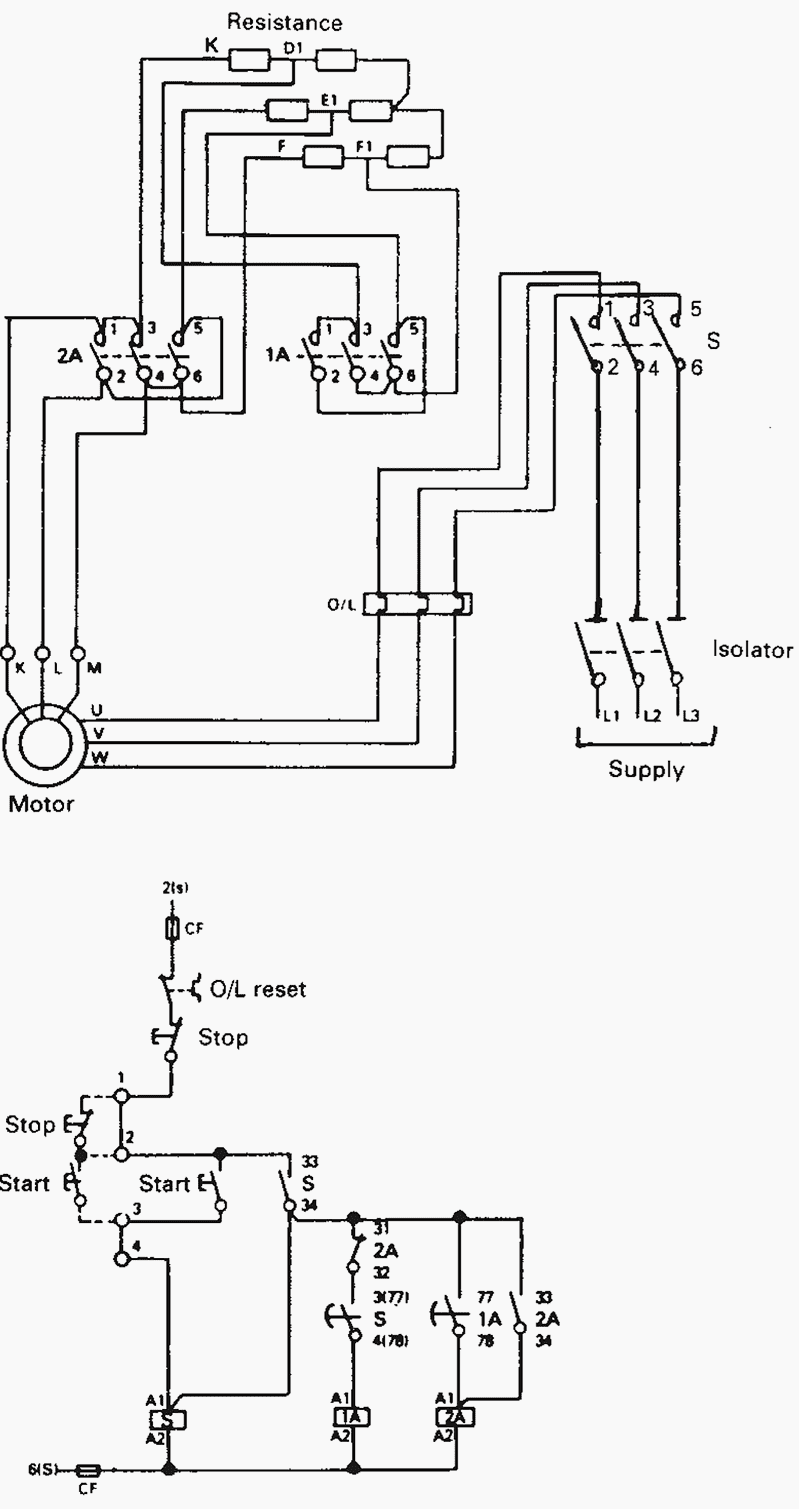

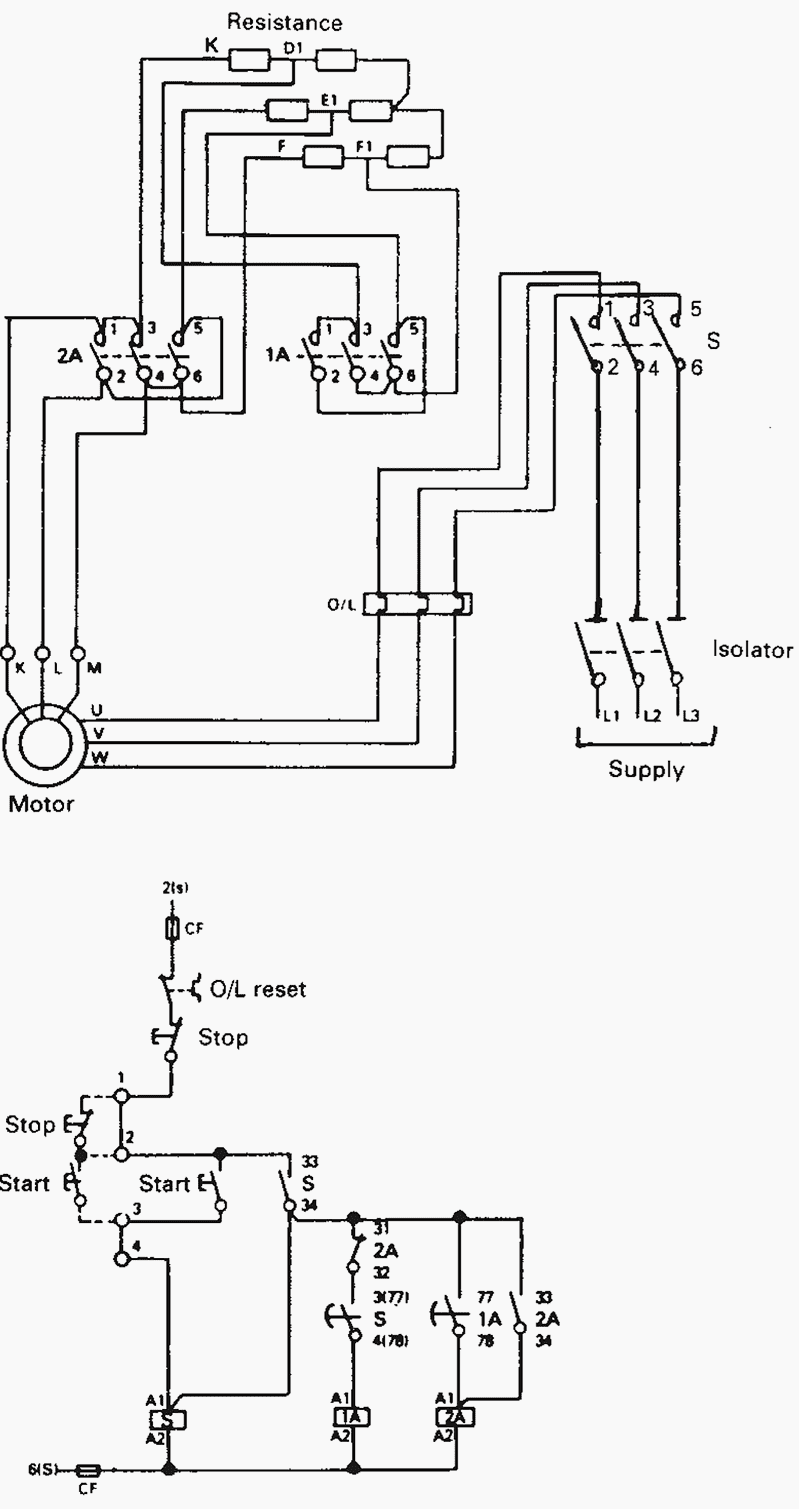

Any of the above may need special consideration and may necessitate the selection of a contactor of a higher AC3 rating than catalogued values would initially suggest. Final or run contactors used in auto-transformer starters (Figure 2) should be selected using AC3 ratings. Star and intermediate contactors should be selected in accordance with catalogue recommendations.

For stator-rotor starters, the stator contactors should be selected using AC2 ratings. Rotor contactor ratings are normally specified by the contactor manufacturer as enhanced ratings based on them being in circuit only during starting.

Another important consideration when selecting contactors is to ensure that the proposed cable conductor can be accommodated by the contactor terminals. Most manufacturers supply this information in their catalogue together with the different types of termination that are available.

A range of contactors is illustrated in Figure 3.

Reference // Handbook of Electrical Installation Practice by GEOFFREY STOKES

Copyright Notice

This technical article is protected by U.S. and international copyright laws. Reproduction and distribution of PDF version of this technical article to websites such as Linkedin, Scribd, Facebook and others without written permission of the sponsor is illegal and strictly prohibited.© EEP-Electrical Engineering Portal.

Related electrical guides & articles

Premium Membership

Edvard Csanyi

Hi, I'm an electrical engineer, programmer and founder of EEP - Electrical Engineering Portal. I worked twelve years at Schneider Electric in the position of technical support for low- and medium-voltage projects and the design of busbar trunking systems.I'm highly specialized in the design of LV/MV switchgear and low-voltage, high-power busbar trunking (<6300A) in substations, commercial buildings and industry facilities. I'm also a professional in AutoCAD programming.

Profile: Edvard Csanyi

Sir, I have an motor of 415V, 3HP, submersible pump so now currently using Direct Online Starter (DOL) So please Suggest me the suitable kind of protection scheme and also, Which kind of contractor to be used, Also the protection Scheme include Over Current protection, Thermal Protection, No load Protection. Please Give me the Suggestion As Soon As Possible

Sir you can use single phasing preventor

Sir I am also an electrical engineer. I love in india. I any suitable job is for available for me please inform.

My email id is

vikashverma096@gmail.com

Mob- +919776184934