In a DC motor, the magnetic field is created by the current through the field winding in the stator. This field is always at right angles to the field created by the armature winding. This condition, known as field orientation, is needed to generate maximum torque. The commutator-brush assembly ensures this condition is maintained regardless of the rotor position.

Once field orientation is achieved, the DC motor’s torque is easily controlled by varying the armature current and by keeping the magnetising current constant.

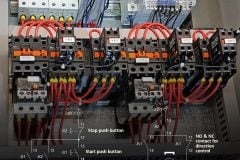

The advantage of DC drives is that speed and torque – the two main concerns of the end-user – are controlled directly through armature current: that is the torque is the inner control loop and the speed is the outer control loop (see Figure 1).

Features of DC Motor Drive

- Field orientation via mechanical commutator

- Controlling variables are Armature Current and Field Current, measured DIRECTLY from the motor

- Torque control is direct

Advantages of DC Motor Drive

- Accurate and fast torque control

- High dynamic speed response

- Simple to control

Initially, DC drives were used for variable speed control because they could easily achieve a good torque and speed response with high accuracy.

- Direct – the motor torque is proportional to the armature current: the torque can thus be controlled directly and accurately.

- Rapid- torque control is fast; the drive system can have a very high dynamic speed response. Torque can be changed instantaneously if the motor is fed from an ideal current source. A voltage fed drive still has a fast response, since this is determined only by the rotor’s electrical time constant (i.e. the total inductance and resistance in the armature circuit)

- Simple – field orientation is achieved using a simple mechanical device called a commutator/brush assembly. Hence, there is no need for complex electronic control circuitry, which would increase the cost of the motor controller.

Drawbacks

- Reduced motor reliability

- Regular maintenance

- Motor costly to purchase

- Needs encoder for feedback

The main drawback of this technique is the reduced reliability of the DC motor; the fact that brushes and commutators wear down and need regular servicing; that DC motors can be costly to purchase; and that they require encoders for speed and position feedback.

While a DC drive produces an easily controlled torque from zero to base speed and beyond, the motor’s mechanics are more complex and require regular maintenance.