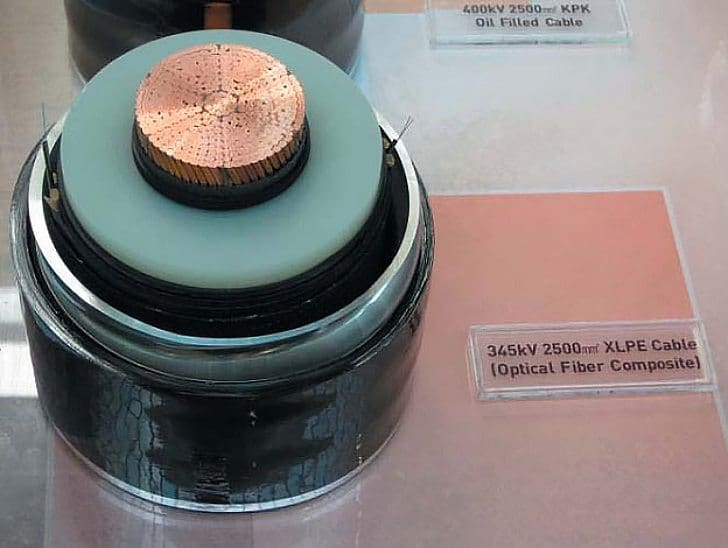

Space is really a critical criterion when discussing electrical cables and wires. In a low-voltage (LV) plastic-sheathed cable with conductor cross-sections of up to 10 mm2 per conductor or in high-voltage (HV) cables (Figure 2), the lion’s share of the cross-sectional area is occupied by the insulating material.

If aluminium rather than copper is used as the conductor material, the additional cross-sectional area required is more or less negligible in comparison.

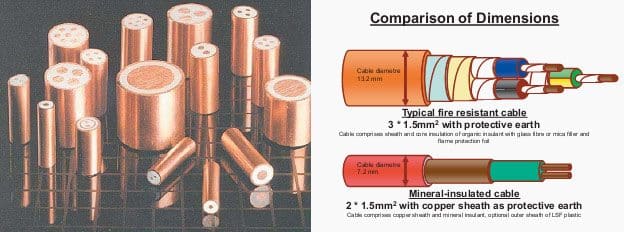

At least that is the situation for conventional plastic-coated cables. Mineral-insulated cables and wires (Figure 3) are not only absolutely fireproof, they also take up much less space (Figure 4) than conventional plastic-sheathed cables.

For a time, these mineral-insulated cables were even equipped with an aluminium sheath, but this never became established and copper sheathing remains the norm.

And in most European countries, copper is still used predominantly, if not exclusively, for electrical installation work in buildings.

So why is it that most European standards do not permit the use of aluminium conductors with cross-sections up to 16 mm2 (or in some cases) up to 10 mm2?

There are three main reasons:

1 Although aluminium is quite ductile, it is not as ductile as copper. The ends of stif wires laid in walls e.g. as connections to flush-mounted sockets or wall outlets tend to break after being repeatedly bent back and forth. This can be problematic if the imminent fracture point is located inside the insulating sheath and if the wire continues to be used. In such cases the fault can remain undetected until the wire has to carry a sizeable current (that is one close to its rated maximum current) and although it could be years before this situation arises, when it does, the conductor material will melt at the fracture point and sustained arcing can occur.

In the worst case, this can cause the aluminium to catch fire and burn like a fuse wire.

2 When exposed to air, the surface of aluminium rapidly becomes covered by a hard, durable oxide layer that does not conduct electricity, thus making it harder to ensure electrical contact. The build up of oxide at points where aluminium wires are terminated or connected, can increase the local electrical resistance of the conductor. The increased resistance can cause elevated temperatures with the risk of heat damage to the insulating materials and possibly fire.

Copper also undergoes oxidation when exposed to air, but perhaps surprisingly, the oxide layer does not inhibit electrical contact, even though the copper oxides (CuO and Cu2O) have conductivities some 13 orders of magnitude less than elementary copper and can therefore hardly be described as electrical conductors.

3 Aluminium has a propensity to undergo slow material creep. When subjected to high pressures, the material will yield over time. One result of this is that originally tight connections may gradually become loose.

Connection technology is available that can deal with this problem and it is worth investing the extra cost and ef ort involved for installations involving relatively few connection points (e.g. HV overhead transmission lines), but not for more complex branched networks such as those found inside buildings.

Concluding…

Because of the second of the three problems listed above, connections involving the ends of aluminium conductors should always be made as tight screw-fastened contacts.

Unfortunately, the third problem discussed above means that these joints are often not permanent. Spring con tacts can be helpful, but they tend to suf er from the problems associated with the insulating aluminium oxide layers. In both cases, the result is a slow rise in the contact resistance at the connection point and thus to an increased risk of fire.

Fortunately, methods are now available for ensuring proper electrical contact between these older ‘protected‘ installations and newer electrical systems. These connectors combine spring-loaded contacts with a special contact paste made from grease and sharp metal particles.

When the connection is made the particles penetrate the existing aluminium oxide layer while the grease protects the contact area from renewed corrosion.

Copper is also the preferred conductor material in high-voltage cables. Although the use of aluminium would result in only a slight increase in the overall conductor cross section, the insulating materials and the exterior shielding required for HV cables are expensive and the greater total cross-sectional area of the cable would cancel out the savings made by using the cheaper conductor material – in contrast to the situation with low-voltage power cables (Figure 6).

If aluminium is chosen as the conductor material, then processing the scrap cable at the end of its (admittedly long) service life will involve the additional step of separating the two materials.

About 45 % of the copper required today is generated from scrap, and the products for which it is used (cables, transformers, water pipes or rooi ng) will remain in use for a long time, on average around forty years. However, forty years ago, the demand for copper was only about half of what it is today.

It follows that about 90 % of the copper used at that time is still in use today. This applies equally to aluminium and other metals. Metals are not consumed, they are used.

Thanks for all the great at information. 1

What is the current capacity of 11 KV power cable mentioned below :?

4 AWG

500 MCM

1000 MCM