Obligatory Checklist

The following tests and checks should be performed at a minimum to ensure that the transformer is ready to be energized. Do not energize the transformer without performing these tests and checks. If any of below explained tests fail and transformer is energized anyway, it may lead to the serious hazard, and that’s not good ;) That’s not what we want.

Let’s see these 15 tests.

1. Insulating Fluid Test

Draw a fluid sample and test its dielectric strength. Dielectric strength of new fluid should be 26 kv or greater.

2. Pressure Test

Check the transformer tank for leaks by pressurizing the tank with dry air or dry nitrogen through the pressure test fitting to a pressure of 3 to 4 PSIG. let the tank stand under pressure for one to two hours, then examine the tank and fittings for leaks. leaks above the fluid level can be detected by applying soap solution to all welds, joints, pipe fittings, and cable connections.

Upon completion of this test, reduce the internal pressure to 1 or 2 PSIG.

3. Insulation Megger Test

Perform a 1000-volt Megger test and a power factor test to ensure that none of the windings is grounded. See the complete procedure here.

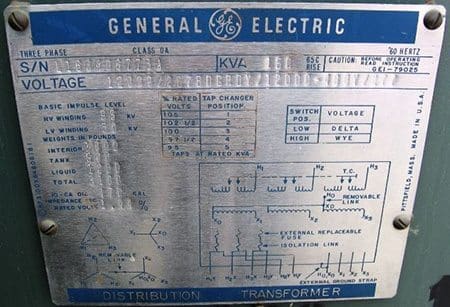

4. Ratio Test

Perform a ratio test at each tap position to ensure that transformer coil ratios and tap changer connections are correct. Read the complete procedure of transformer turns ratio test step by step.

5. Continuity Test and Resistance Test

Perform a continuity check on each winding. Measure the winding resistance of each winding and compare results to factory test values.

6. Line Connections

In preparation for making line connections, check to make sure that all mating connector surfaces are clean and smooth. Connections must be tightened appropriately to prevent overheating and possible subsequent failure of the connection.

Connections to should be made with care to avoid placing undue stress on the bushings.

7. Tap Changer Setting

Check the tap changer setting to ensure it is set to the proper position for the required voltage. See an example of transformer tap-changer correct adjustment.

8. Delta/Wye and Series/Multiple Switch Settings

Check delta/wye and series/multiple switch settings to make sure they are set correctly.

If these connections are made using an internal terminal board, check to ensure that these connections are made properly according to the chart on the transformer nameplate.

9. Grounding

Check to ensure that the transformer tank is permanently and effectively grounded. The transformer tank ground pad is located near the bottom of the tank.

10. Wiring

Check wiring of control and alarm circuits (if provided) to make sure there are no loose connections and no damage to insulation.

11. Fluid level

Check to make sure the fluid level as indicated by the fluid level gauge is as follows:

12. Tank Finish

Check all painted surfaces to make sure that there is no damage or corrosion.

13. Bolted Connections

Check all bolted connections for tightness.

14. Tools

Check to make sure that all tools and equipment are accounted for and have been removed from the transformer.

15. Fluid Temperature

Read the fluid temperature gauge and make sure the temperature is no lower than minus 20°C before the unit is energized.

Reference: Installation, Operation, and Maintenance of Medium Power Substation Transformers – Howard Industries

Thanks for the good article but the 1st item Insulating Fluid Test requires further clarity on what is required for this important component. It vital to draw an oil sample(IEC 60475) but the testing requirement in accordance with IEC 60422 is more than just doing the Dielectric Strength and reference should be made to the requirements to IEC 60422 Table 3. Unfortunately your reference that the insulating oil should have Dielectric Strength > 28 kV needs to be questioned as the IEC Standard for the Voltage classification for the Transformer you have in this article should be >60 kV.

Please I want us to be communicating constantly through email and wasap .I really feel delighted for this useful information.

How do I pressurizing the tank with dry air or dry nitrogen through the pressure test fitting?

any procedures?

Thanks a great deal for this.

Was the CT ratio coil being connected properly to the meter gauge. Chk the passing through cable to the CT coil

Was 2012 I worked with al GAhaz trading company one year WITH SWEET progact THIS IS MY STORY

Hi,

Just I want to know about ELR. We have connected ELR With Incoming panel(800A). That ELR is getting Trip within Seconds. Equipments are not getting any Earth Leakages. No shock effect from equipments… I am not able to Understand what is exact problem..Pls Let me know Reason.

Thanks&Regards

Prasad Reddy

9886300137

Very thanks for this article

I’m very glad about this, but if i want know more, how to discussaed with you as electrical engineer?

I am a protection engineer and I carry out all such tests . I just want to know that why magnetic balance test of 160MVA tfr is diferrent from < = 100 MVA tfr.

Good information for an executive.

Very very important. Articles for sub station maintenance. Great thank u

Thanks for such a informative article

nice information

Thanks a lot for such a useful article. I have a question related to the resistance test where i have to read through the Megger. Is it right to compare with short circuit test and open circuit test which will provide me the magnetization Resistance and core loss resistance??

I will aprreciate answering my question

For Comparison, this can be used and usually is

Also need to check if:

– Radiator valves are open

– Cooling fan motors rotate in the correct direction

– There are no visible oil leaks

– Off-load tap changer handle has been locked

I believe that there are other important test like core balance, short circuit etc

Exactly. But for Beginners this is quite helpful for getting the idea of testing involved in the process.

Many thanks

thank you Mr.Edvard ,, very nice one but i think there is other tests to be added here like the polarization index and tan delta test.

Thank you for your articles are so rich.

Its useful data.Thanks

Amazing post, brother. Thanks.

Francisco.

Good app it is..I am Electrical Engineer who wants to improve the knowledge day by day..Thanks for this great app…Mr.Edvard..

many thanks sir

Excellent article. You must add something about funcional test. For example test of ventilation system. It’s my suggestion.

Please remove my photo, the first photo (DGA Syringe), from your publication. It is copyrighted and used without my permission.

Thank you.

My apologize Mel. Your photo has been removed.

Very good article. Air cell in conservative to be included in final checking list.

Its helpful

Your article is very nice and useful..

Thanks for every….