Electrical grounding

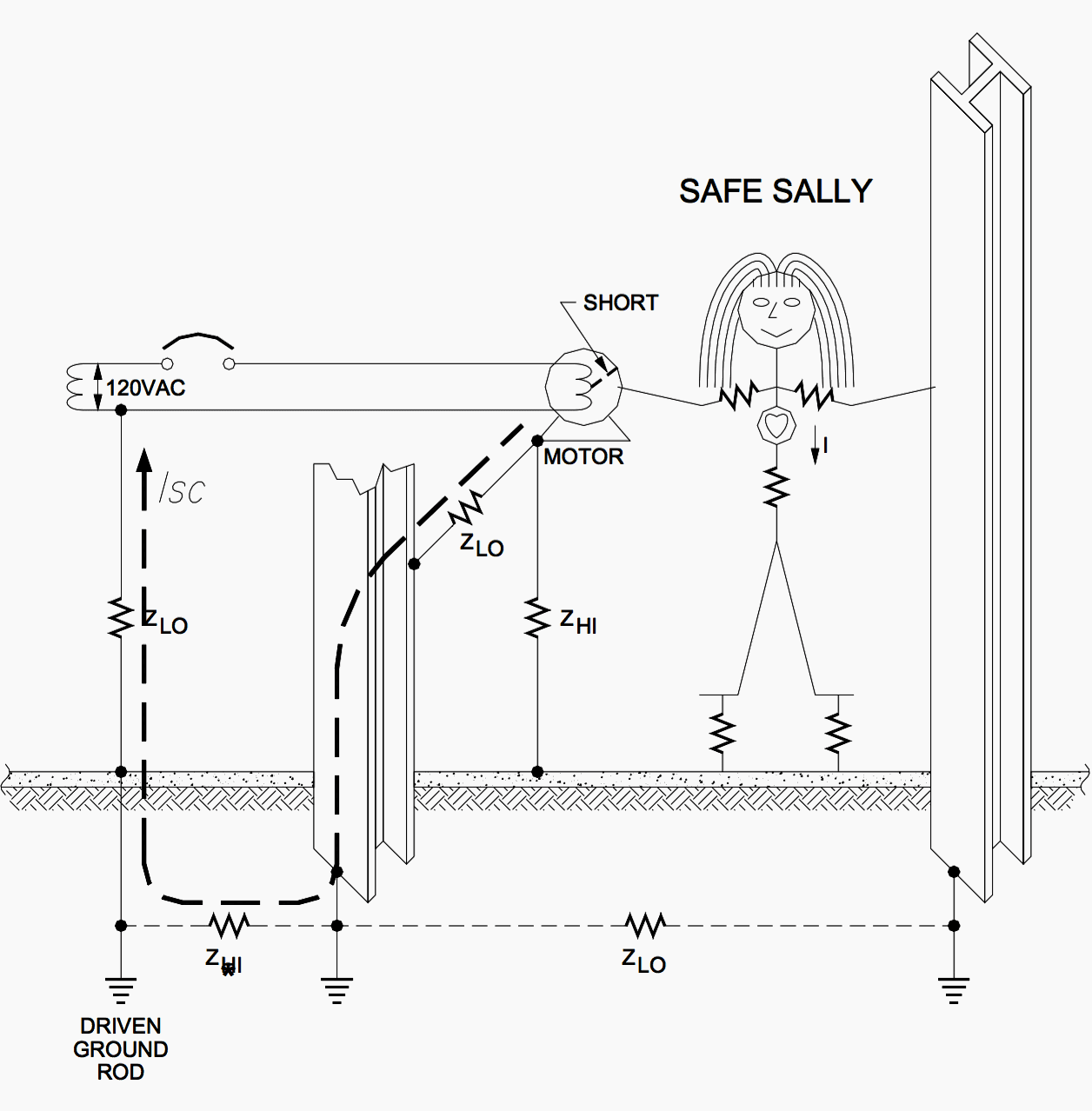

This is a discussion of the basic principles behind electrical grounding systems and how grounding is related to safety and the effective operation of circuit protection devices such as fuses and circuit breakers.

The discussion moves quickly from a basic study of grounding to simple examples of a single building installation and onto facilities with multiple buildings and structures. Finally the discussion will briefly cover grounding as it applies to lightning protection and the control of static electricity.

Grounding to most engineers, technicians and electricians is a simple subject and little attention is paid to it other than knowing that something is required. To some people there are grounds and then there are “Clean Grounds”.

Thirty years ago when computers were relatively new, there were many approaches to grounding, particularly for electronics and computers.

Some of these approaches established what was called a “Clean Ground” which was often isolated from the power grounds.

The research resulted in the basic science behind grounding. This subject is not as simple as once thought and one needs a clear understanding of the basic principles. First, the ground or grounding of a circuit is a misnomer. For most purposes the term means earthing or connecting the circuit to earth.

In actuality, it’s connecting the circuit to a common point of reference – for most systems that is the earth.

| Title: | Basic principles of electrical grounding for electricians and technicians by John C. Pfeiffer, P.E. Pfeiffer Engineering Co., Inc. |

| Format: | |

| Size: | 732 KB |

| Pages: | 43 |

| Download: | Right here | Video Courses | Membership | Download Updates |

Proper Grounding and Bonding must be in place.

Is it advisable to link both the neutral and the earth together in distribution board.

Pl.let me know the complete information about chemical earthing.Its installation , chemicals used and resistance required.Thank u.

Earlier for Earthing; Salt & Charcoal were being used to reduce the resistance values, important for quick dispersal of current into earth. The salt dissolves in the moisture in soil and gets washed away with time. Also, salt being corrosive eats away the earthing electrode thereby reducing surface area of the electrode. In Chemical earthing; chemical compounds are used which are hygroscopic, highly conductive (with resistivity less than 0.12 Ohm Meter as per IEEE 80 clause 14.5 d) & non-corrosive thereby increasing the life of earthing. Installation process is same as that of conventional Salt+Charcoal earthing wherein Chemical compounds (Ground Enhancement Compounds) are used in place of Salt & Charcoal. The amount of Chemical to be used depends on the resistance value required vis-a-vis the Soil Resistivity.

my comment has not come

In the attachment , pg 33/43 . what is that outer line which encloses both the trf, main panel and sub panel , load.

I understand , it must be some large earth flat or cable around the building.

is it right?

Also i understand that because of high resistance in earth loop, NEC recommends separate ground conductor between main panel and sub panel as shown in pg33/43. Right?

I think there should be a discussion on theft prevention and efforts made to prevent it. I believe that anyone how steals any part of an earthing system that results in a death should be charged with second degree murder. In Africa it is a huge problem.