Thermal Design of Cables

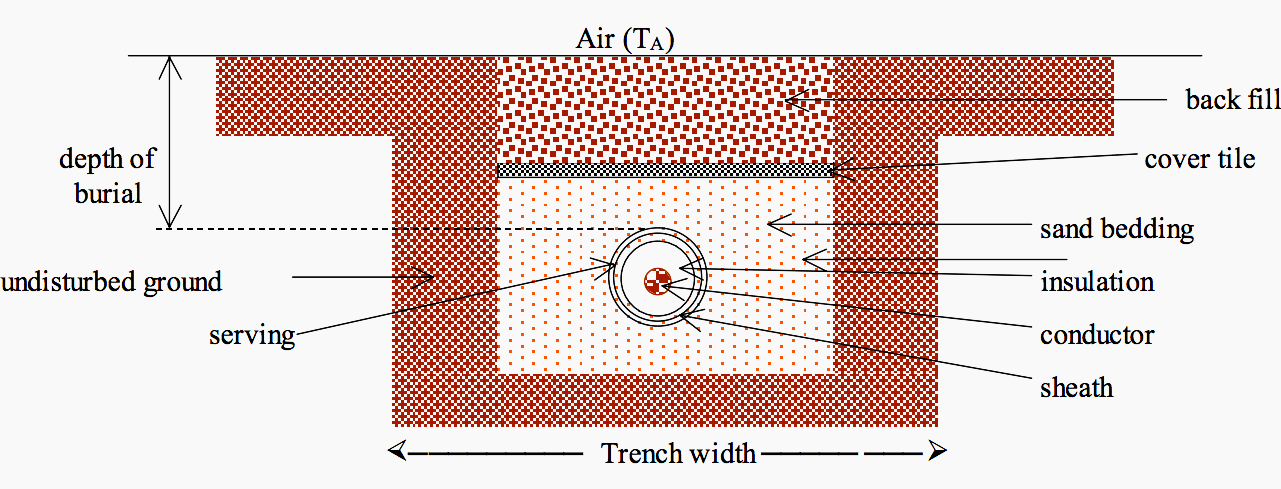

Underground cables are installed in trenches of rectangular cross-section. After excavation of the trench, a layer of sand is placed in it to serve as a bedding, as shown in Figure 1.

The length of cable is pulled in along the trench and covered with a further layer of sand. Sand free from flints and stone is employed to avoid damage to the cable serving during pulling and initial back filling. Above the cable and sand bedding are placed cover tiles to protect the cable from mechanical damage from subsequent excavation activities.

The excavated material is replaced in the trench and stamped to consolidate it. The minimum trench width that can be conveniently excavated is about 700 mm (27 inches), and for safety reasons, the minimum depth of burial in normal circumstances is 900 mm (36 inches).

When more than one single core cable is laid together (as is required for three phase systems exceeding 150 kV), the heat produced by one conductor affects the other and the heat factors need to be modified. When the spacing between the cables is increased, the heat produced by the circulating currents between the cables will increase whereas the eddy current losses decrease.

Thus there is an optimum spacing for cables and various alternatives may have to be evaluated before the economic arrangement is finally selected.

Current rating of Cables

In a cable, the factor which ultimately limits the current carrying capacity is the maximum operating temperature which may be sustained by the cable throughout its life without risk of damage or deterioration.

The heat so generated is radiated to the surroundings. The current that can be carried depends on the conductivity of the surrounding medium as well, so that the same cable would have different ratings depending on whether the cable is buried or not.

| Title: | The basics of high voltage cables for underground energy transmission – J. R. Lucas |

| Format: | |

| Size: | 268 KB |

| Pages: | 27 |

| Download: | Right here | Video Courses | Membership | Download Updates |

My latest invention shown in this video for building an InfinitPipe on site has another great use for protecting high voltage cables. (https://youtu.be/EGsipDj0dEA ) We could use a two-piece mandrel, place at around the cable and as the continuous pipe/conduit is built, pull it over the cable — for as long a length as needed. This can be done without the need to disconnect the cable at the end for access! The conduit is very strong and can be filled with pressurized gas or liquid. Do you see any application for this?

I am trying to download the file but I always receive the information “Not Found”.

I’m trying to download the pdf, but I can’t.

Could you me the paper?