About this technical guide

This guide presents and illustrates all the best practices to apply when building low-voltage switchboards, in compliance with IEC standards 61439-1 and -2. The application of these rules means strict compliance, not only with applicable regulations and standards, but also with manufacturers’ recommendations.

This guide has been updated to take into account recent changes to standards and the latest technological advances in switchboard assembly and installation. It draws on experience acquired by Schneider Electric and its customers over many years.

It is intended for use by panelbuilders in the factory and on-site and also by design engineers to integrate design rules.

It is structured according to the logical procedure for switchboard building from the receipt of components in the workshop to the transport and installation of the complete switchboard on site.

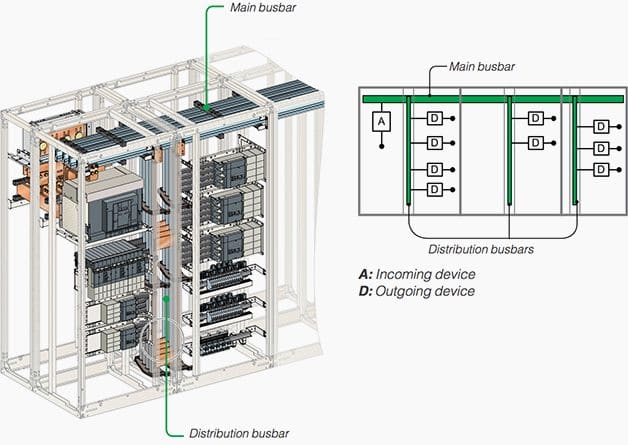

Power busbar

Power is distributed in switchboards through the following means:

- A main busbar that distributes power horizontally between the various switchboard columns. It may be installed on the top, middle or bottom of the switchboard depending on the type of switchboard, customer specifications and/or local practices,

- Distribution busbars connected to the main busbar. They provide power to outgoing devices.

IEC 61439-1

The following must be taken into account when choosing a power busbar:

- Environmental characteristics of the switchboard (ambient temperature, IP degree of protection, pollution),

- Type of switchboard installed regarding to validation test,

- Characteristics of the client’s power supply: on the top, middle or bottom,

- The rated current of the short-circuit: Icw.

The installation of a power busbar consists in the following steps:

- Select the busbar material,

- Size it (busbar section, number of busbars per phase) and define its position in the switchboard based on the client’s incoming devices,

- Install it in compliance with the creepage and clearance distances of the standard,

- Fasten it according to good practice.

Protection of persons

The installation must ensure the protection of persons:

- Against direct contact by installing the appropriate internal partitions (forms) or by installing live parts out of reach.

- Against indirect contact by creating an equipotential bonding inside the switchboard (PE/PEN protective conductor and earthing of the grounding electrode conductors).

Current transformers

The current of a power busbar is measured using a current transformer (CT) such as a busbar passing current transformer. The main role of the current transformer is to lower the value of the current to be measured to a value that is acceptable for metering devices (usually 1 to 5 A).

| Title: | How to assemble LV electrical switchboard – Technical guide – Schneider Electric |

| Format: | |

| Size: | 26.08 MB |

| Pages: | 292 |

| Download: | Right here | Video Courses | Membership | Download Updates |

thank you for such important piece of technical know how

For low voltage metering panel, is there a necessity to ground the neutral wiring of the CTs? Since the induced voltage is low, it will not damage the meter or the wiring, which is typically rated about 500V – 700 V.

We are panel builders. We agree that in switchgear panels, separation of areas is practical, but not always in controlgear panels. We saw recently a very large controlgear panel shipped from India with 42 small starters. They were beautifully separated. Unfortunately, most of them were interconnected. Some of the starters were almost on floor level and even connections to them was difficult. There was not enough space for the glands of PVCSWA cables. The consulting engineer specified, in writing, heat, light and smoke detectors for each starter, None were fitted and the supplier said that they would not be able to pipe the gas into the units. As you can see modules in such cases are totally impractical. We normally put such starters into one space, insulate the busbar area and give it plenty of CO2. I would like hear the views of other panel builders.

Your materials have been very helpful

Nice to know.ty