Introduction to the quality inspection

Justification of quality inspection

The implementation of the quality process in production plant will entail to organised the work station on the way to reach the quality target as per imposed by the standard. A quality inspection process has always been recommended to all our partner and subsidiaries.

Part of the quality insurance, it is a normative obligation of the IEC 60439-1 standards which stipulate that three routine tests should be perform in the scope of the quality inspection procedures to complete the type tests:

- Giving the equipment the TTA label (Type Tested Assembly) and

- Which are bound to the panel builder’s responsibility.

- Inspection of the assembly

- Dielectric tests and / or measurement of insulation resistance

- Checking of protective measures and of the electrical continuity of the protective circuit

Human factors

The specificity and complexity of low voltage equipment, the numerous human interventions, and thus risk of errors are the principal source of mistakes in our field, so the main reasons of the implementation of the quality inspection process.

Inspection during manufacturing

To ensure the conformity of the product or sub-assembly with the expected needs, the quality assurance programme may recommend the implementation of a specific inspection procedure. Done on parts of an assembly or at the end of various assembly operations.

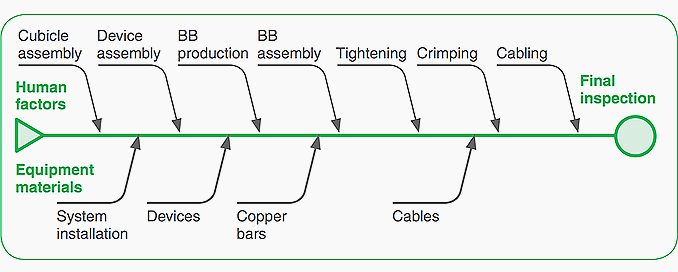

The following diagram represents the operations on which in-process inspections are carried out and the main items concerned by incoming quality inspection.

The reasons for performing inspection during the manufacturing process is the complexity of some equipment systems. It could be necessary to perform a quality inspection process during manufacturing to ensure the conformity of parts or assembly stages.

| Title: | Low Voltage Switchboards – Quality Inspection Guide 2013 – Schneider Electric |

| Format: | |

| Size: | 12.6 Mb |

| Pages: | 72 |

| Download: | Here 🔗 (Get Premium Membership) | Video Courses | Download Updates |

One on the reasons for current unbalance is due to not proper and symmetrical wound iof coils inside the motor.The case is worse for rewound motors.

What is the reason for unbalancing motor current.2

unbalancing in current due to loose connection, high resistance of one phase cable, carbonization on one Phase of Contractor or MCB/MCCB.

also not proper grounding/bounding of equipment.

At that moment motor was nt operating

Please check the load on that phase circuit that may have load still connected to it, like power to lighting and computer desk tops or fan points or other single phase loads.

Sir, what could be possible resons for moisture affecting the encoder of a motor???..

Environent usually…