Transformer Types

Dry type transformers and liquid filled transformers are the two general categories that can be used to classify transformers for the purposes of sudden pressure relay applications. Dry type transformers are non-ventilated and employ air, nitrogen, or another inert gas as the insulating and cooling media. These transformers are also known as dry type transformers.

The flow of gas can be maintained at zero gauge pressure, can be forced to circulate, or can be naturally circulated.

The insulating and cooling medium of liquid-filled transformers use a wide variety of liquids to accomplish their functions. Chemically speaking, the liquid is normally mineral oil; however, it might also be synthetic oil or a fluid that is less flammable, such as polydimethyl siloxane, which is based on silicon. It is possible for the fluid flow to be either naturally or artificially circulated, and it can be either direct or indirect.

External heat exchangers, which are commonly used in liquid-filled transformers, are typically cooled by either air or water, regardless of the circulation methods that are used.

A combination gas-liquid system is utilized in the layout of certain liquid-filled transformer types. Sealing and non-sealing are the two categories that are used to categorize gas-liquid systems. However, only the sealed kind is able to maintain gas volume, whereas both types are able to retain liquid volume.

An example of a straightforward positive pressure sealed system is a single tank transformer that is equipped with a nitrogen blanket and receives its supply from a gas bottle.

For the purpose of voltage regulation, transformers may make use of a load tap changer (LTC). It is common practice to store the LTC in a separate tank that is filled with liquid. Monitoring of the pressure in the LTC tank could be beneficial and might be incorporated into the plan for the simultaneous pressure relay.

Types of Sudden Pressure Relays

Sudden pressure relays often fall into one of two categories: pressure sensing or flow sensing. What follows is a description of the fundamental working principles of each:

Principle #1 – Pressure Sensing

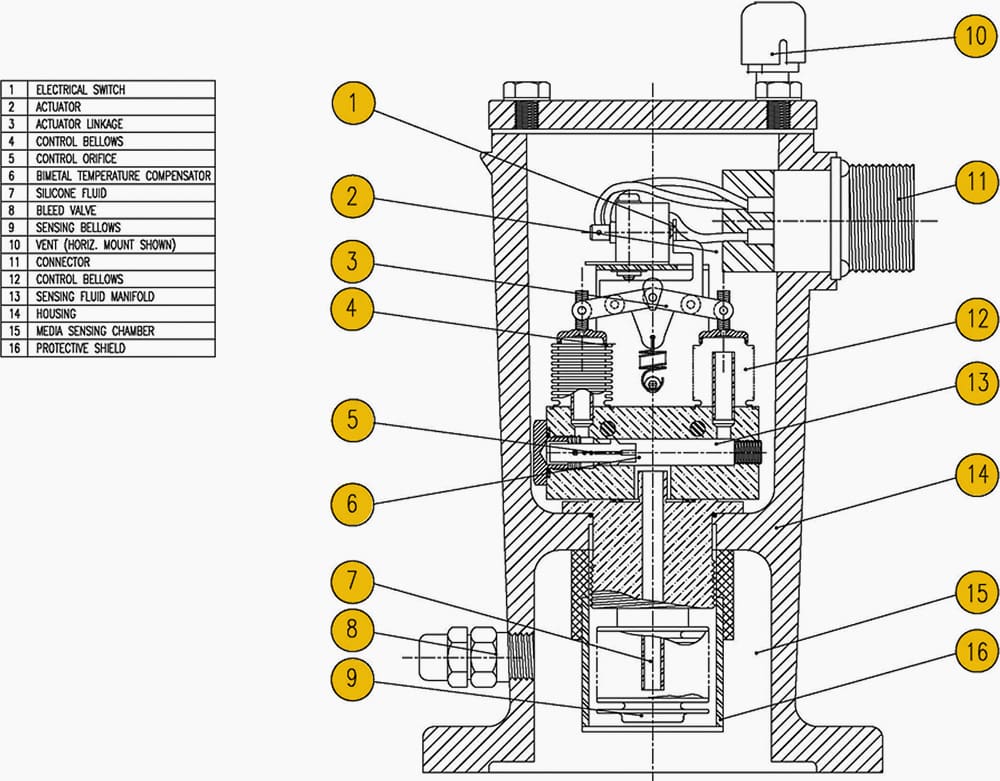

One approach involves positioning the sensing connection in the gas compartment of a pressurized transformer, with the sudden pressure detecting relay situated on top of the transformer. An “In Gas” abrupt pressure relay is what this is called.As illustrated in Figure 1, the sensing chamber is equipped with a micro-switch, bellows, and an aperture that links it to the reference chamber.

As a function of temperature, the internal gas pressure of a transformer will rise and fall during normal operations. Due to the slow nature of the pressure shift, enough flow can pass through the aperture to maintain a constant pressure in both the sensing and reference chambers.

The device reset is triggered by the pressure within the transformer, and it usually takes less than 90 seconds for the reset to occur.

Figure 1 – Sectional View of a Mechanical Pressure Sensing Sudden Pressure Relay

The second approach involves positioning the sudden pressure sensor relay on the side of the transformer, specifically below the minimum oil level in the tank. The relay detects the state of the oil inside the primary transformer container. This device is sometimes referred to as a “Under Oil” sudden pressure relay.

This relay type can be utilized on any oil-immersed transformer. The sensor chamber comprises a bellows, a micro-switch, and an aperture that establishes a connection between the sensing chamber and the reference chamber. This setup is analogous to the “In Gas” relay, but it is specifically engineered to function with the transformer fluid. Figure 1 also depicts this particular iteration of the pressure sensing relay.

The latest iteration of the pressure sensing relay was introduced to the market during the mid-1990s. A manufacturer offers a microprocessor-based relay that can independently monitor rapid pressure rise, gradual (static) pressure rise, and includes a built-in seal-in relay. Additionally, it contains an analog current loop that enables SCADA or remote pressure sensing.

It can be utilized for both “in gas” or “under oil” applications through adjustment settings. Figure 2 displays this device.

Figure 2 – Sudden Pressure Relay Control Panel: Relay Housing with Connecting Control Wires

Principle #2 – Flow Sensing

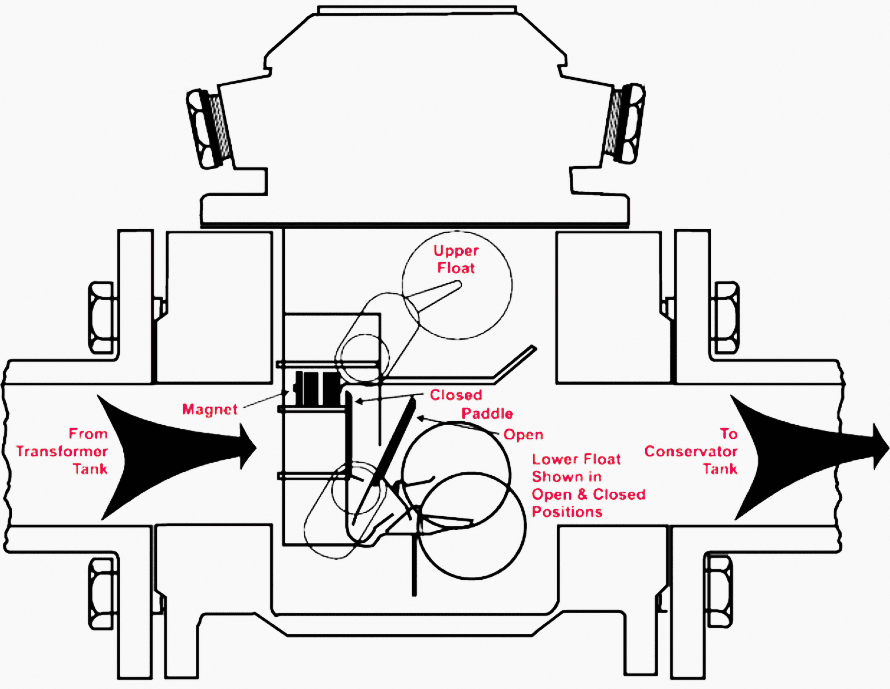

The flow sensing sudden pressure relay, popularly known as the Buchholz relay, is positioned between the transformer tank and an oil conservator. This relay typically employs two distinct detection principles to identify problems in transformers.

One approach involves the buildup of gases within a sensing chamber.

When the gas volume reaches a suitable level, typically between 100 and 200 cm3, a contact is activated. The second method identifies the presence of oil movement from the transformer tank to the conservator. An output contact is closed when the speed of the oil flow reaches a range of 0.85 to 1.15 m/s. Figure 3 depicts this gadget.

Figure 3 – Sectional View of a Buchholz Relay

Sudden Pressure Relay Applications

Sudden pressure relays are utilized to identify anomalies that are typically not detected by relays based on current, such as overcurrent or differential relays. They can be used for virtually any size and style of transformer that is filled with liquid. The selection of the sudden pressure relay is typically influenced by factors such as the dimensions of the transformer, its position within the power grid, the financial implications, and previous operational history.

The issue of tripping and/or alarming has been a persistent worry since the initial stages of the development of this relay technology.

When to Use Sudden Pressure Relay?

Examples of faults with low current magnitude that may be undetected by typical current-based relays, as well as other uncommon events, are:

- Turn-to-turn faults

- High-resistance joints

- High eddy current between laminations

- High resistance faults

- Hot spots on the core due to a short circuit of the lamination insulation

- Core bolt insulation failure

- Faulty joints

- Loss of oil due to leakage

The use of sudden pressure protection can also provide assistance in safeguarding grounding transformers and transformers with intricate circuits, such as those involving phase shifting and phase regulating. The sudden pressure kind of relay is not affected by the precise position of the winding fault.

Tap changer mechanism compartments may also utilize sudden pressure relays.

The utilization of a sudden pressure relay may be determined by the subsequent considerations:

1. The Cost

It is reasonable to justify extra protection for a more expensive transformer. Whether or not to install the safeguards on cheaper transformers is an entirely different story. In addition to the transformer’s direct cost, there may be additional expenses associated with labor, downtime during replacement, and revenue loss from the consumers fed by the transformer.

2. Transformer MVA size

Since a larger transformer usually means a more expensive transformer, higher levels of load, and more customers, it stands to reason that more protection would be warranted for a larger transformer.

Suggested Guide (PDF) – Power transformer energization problems and modeling for calculation of inrush currents

Power transformer energization problems and modeling for calculation of inrush currents

3. Transformer location in power system

Perhaps the cost of installing a sudden pressure relay is reasonable if the transformer is situated in a radial system, which is essential for ensuring customer service. Since there are other ways to switch the loads, small transformers in a shared substation might not need a sudden pressure relay.

It may be necessary to place sudden pressure relays on transformers that supply high impact clients, such as hospitals, regardless of the cost.

4. Past operating experience

Mistakes with the design led several utilities to either eliminate or change the sudden pressure relaying from tripping to alarm only. Such modifications were more prevalent on earlier, less secure methods.Utilities that switched to an alarm-only design or eliminated the trip may want to reevaluate their options in light of the fact that newer relays and designs have decreased misoperations.

After deciding to install a sudden pressure relay, there are a few more details to sort out, such as the kind of the relay and whether it should trip or sound an alert.

| Title: | How to fully protect the transformer from sudden pressure and avoid future incidents? – IEEE K6 Working Group (Randy Crellin (Chair), Don Lukach (Vice Chair), Pat Carroll, Mark Carpenter, Arvind Chaudhary, Steve Conrad, Dominick Fontana, Rafael Garcia, Bill Gordon, Gene Henneberg, Barry Jackson, James Platt, Elmo Price, Mark Schroeder, Greg Sessler, Charles Sufana, and Don Ware) |

| Format: | |

| Size: | 800 KB |

| Pages: | 72 |

| Download: | Right here | Video Courses | Membership | Download Updates |

Suggested Reading – Fundamental concepts of schematic drawings: Going deeper into analysis and design intricacies

Fundamental concepts of schematic drawings: Going deeper into analysis and design intricacies