Transformer Protection

In order to provide the most comprehensive explanation of the protection characteristics of a transformer, the following questions should be answered: Exactly why is it necessary to protect a transformer? Specifically, what are the goals of the transformer protection system? What are the factors that lead to the breakdown of transformers?

The following are some of the reasons why a transformer need protection:

- In the event that the transformer breaks, the plant will often experience a complete failure in its ability to function.

- A prompt fault clearing would typically prevent catastrophic damage to the transformer, provided that it is appropriately protected on the transformer.

- When a transformer does fail, proper protection and prompt clearing will minimize damage, system disturbance, and the magnitude and duration of the outage.

Objectives Of Protection

The objectives of protection are as follows:

- To protect the electrical system from the failure of the transformer;

- To protect the transformer from disturbances in the electrical power supply;

- To protect the transformer as much as possible from malfunctions that occur within the transformer itself; and

- To protect the transformer from the environment in both a physical and electrical sense.

Causes Of Transformer Failure

The failure rate of transformers, at 76 failures per 1000 transformer years, is statistically lower than that of any other electrical equipment, such as motors, cables, and switchgear, which is favorable news.

Transformer failures can be categorized into the following causes: winding failures (the most prevalent), persistent overloading, bushing failures, phase and ground faults, transient overvoltages, and environmental factors (e.g., ice, wind, lightning, etc.).

Through-fault Protection (Liquid-mmersed Transformers)

Four elements influence through-fault protection for liquid-immersed transformers:

- Transformer category (e.g., number of phases and kVA rating of fault occurrence)

- Fault incidence zones (e.g., frequency of faults)

- Transformer connections (e.g., Δ-Δ, Δ-Y, Y-Y, or Y-Δ)

- Transformer damage curves (e.g., Cat I, II, III, IV)

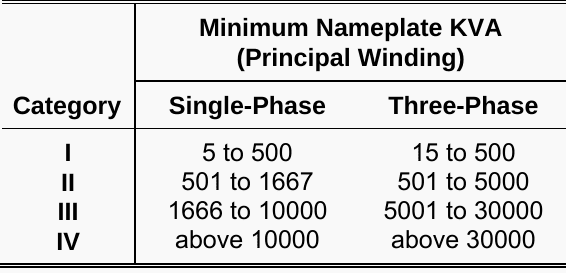

Transformer Categories: ANSI/IEEE Standard C57 categorizes transformers by number of phases (e.g., single or three-phase) and size (e.g., kVA ratings), as listed in Table 1.

Table 1 – Transformer Categories

Fault Incidence Zones:

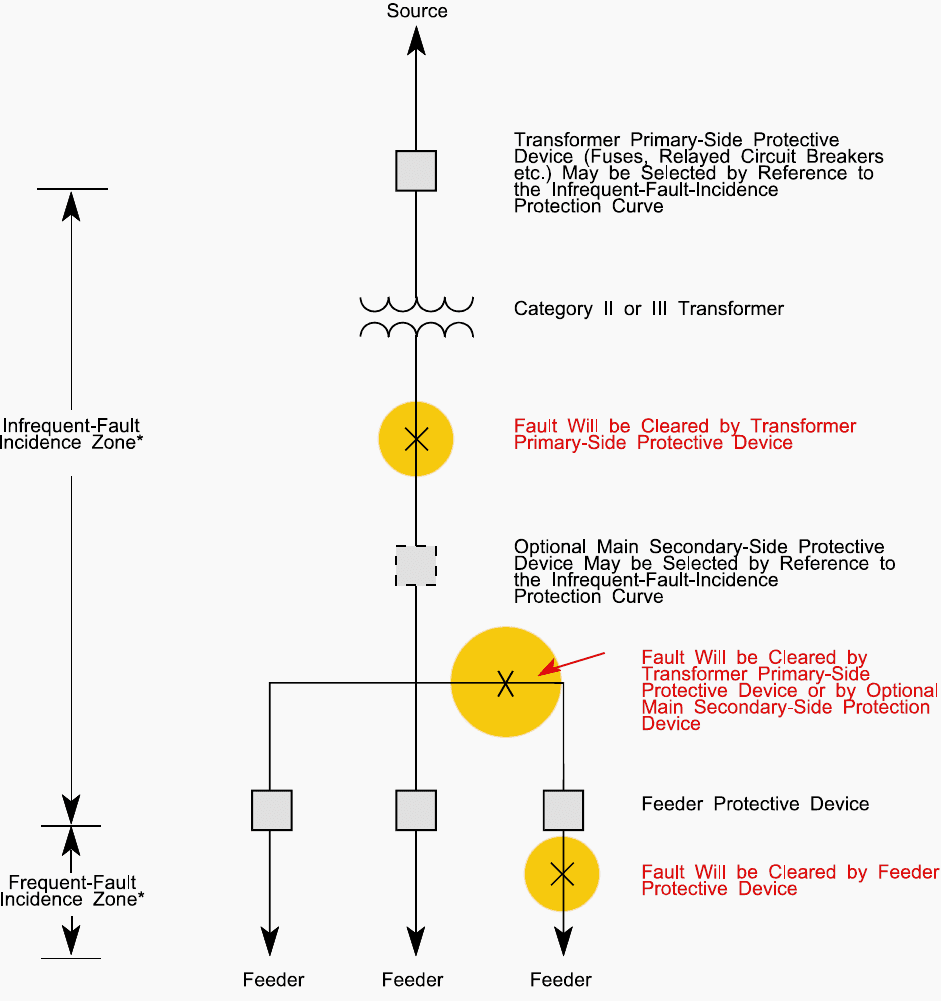

Transformer damage resulting from faults is cumulative, and the number of through-faults a transformer can withstand varies significantly across different applications. Transformers with secondary side conductors enclosed in conduit or otherwise isolated, commonly seen in industrial power systems, have a markedly low occurrence of through-faults.

Transformers equipped with overhead lines on the secondary side, commonly located in utility distribution substations, exhibit a significant frequency of through-faults.

Figure 1 illustrates the fault incidence zones (frequent and infrequent) for a standard industrial power system.

Figure 1 – Transformer Through-Fault Incidence Zones

Transformer Connections:

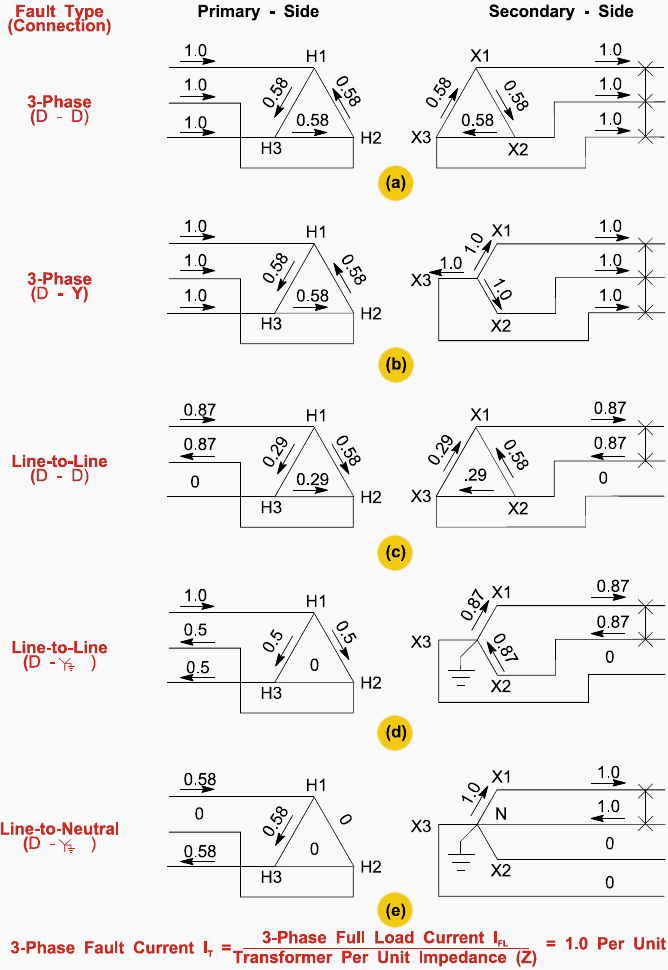

Another consideration for transformer protection is the impact of external secondary faults on delta-delta and delta-wye connected transformers, as depicted in Figure 2.

The through-fault protection curves are predicated on three-phase secondary faults. For Δ-Y connected and solidly grounded transformers experiencing single line-to-ground failures on the secondary side (Figure 2e), the curve values should be diminished to 58% (1/3) of the three-phase curve values.

For Δ-Δ linked transformers experiencing line-to-line failures on the secondary side (Figure 2c), the curve values should be diminished to 87% (3/2) of the three-phase values. No modifications are necessary for the remaining connections, as at least one phase of the primary side will register 1.0 per unit current.

Refer to Figures 2a, 2b, and 2d.

Figure 2 – Effects of Secondary Faults on Transformers

| Title: | Transformer Protection Handbook |

| Format: | |

| Size: | 1.40 MB |

| Pages: | 63 |

| Download: | Here 🔗 (Get Premium Membership) | Video Courses | Download Updates |

Suggested Reading – Managing power transformers in service: The most important economic aspects

Managing power transformers in service: The most important economic aspects