Principles of Energy Management

Maintaining a reliable supply of electrical power to consumers is a highly complex process as most of this power cannot be stored and the individual components of this process, forming what is called a power system, can be spread over a wide geographical area. The purpose of power system management, also referred to as Energy Management, is to monitor, control and optimize this process in real-time.

The basic functionality of power system control is found in the Supervisory Control and Data Acquisition (SCADA) function that collects and records values and statuses acquired from the power system elements via remote telemetry to enable control center operators to supervise and control the power system.

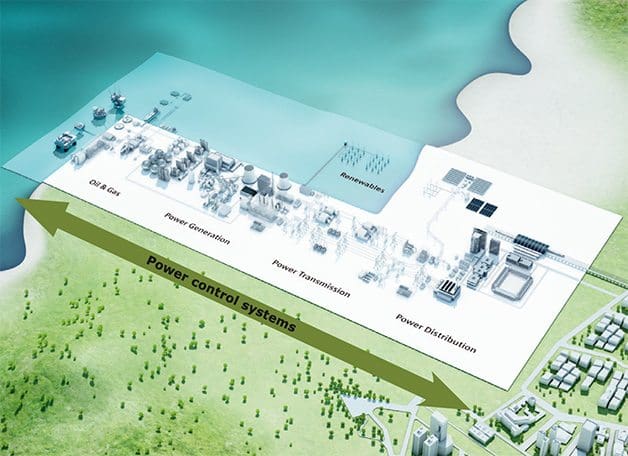

Other decision support functions complement this function to provide power system management for a secure and optimal process (figure 1).

The Role of the Network Control System in Power System Management

History

The control and information technology used for the management of a power system has its origins in the automation of power plants. The primary objective was then to improve operational reliability (Figure 2).

With the increasing number of power plants and their interconnection via the grid, primary frequency control, also referred to as generator droop control, was no longer sufficient. To improve on power delivery quality, coordination, including secondary frequency control, of power generation and, later, external interchange became unavoidable and was promptly implemented in control centers.

Before the introduction of the transistor in 1947, the vast majority of protection and control devices used in power system control were of electromechanical design.

In the early days, information was transmitted by means of relays and pulse techniques, but with the introduction of electronics it became possible to implement increasingly efficient transmission means. At the end of the 1960s, with the introduction of the first process control computer, the first computer assisted power and frequency control systems became possible.

As computers became more efficient in the 1970s, the switchgear in transmission networks was also gradually monitored and automated with the aid of power system control technology.

Because of the inadequate graphics capability of computer terminals at that time, the master computers were used mainly for remote monitoring of unmanned stations or for performing calculations to support operations. The network state was displayed visually on large switch panels or mosaic walls that were also used to control the switchgear.

Only as the performance of graphical displays improved were Operation management functions gradually transferred to VDU-based Workstations.

As computing power continued to increase in the mid-1970s, it also became possible to use computers for optimization processes.

These programs also provided a method of economically assessing the exchange of energy, a basic requirement for energy trading later on. Increasing computer power was, however, also harnessed to further develop man-machine communication towards greater user friendliness.

| Title: | Energy Management – SIEMENS |

| Format: | |

| Size: | 1.93 MB |

| Pages: | 40 |

| Download: | Right here | Video Courses | Membership | Download Updates |

I can’t download th white paper. Thanks

I can’t get acces to the articles or download them I would like some help if it’s possible.Thanx

Can you access box.com?