Electrical System of Bakery

A small bakery with just a counter and storage areas is simple to design. The electrical design follows the layout for a house, but care must be taken on loading factors if direct-acting electric heaters are switched on all day.

These days, many shops and stores have specialised equipment for cooking food or providing other services such as shoe repairs or photographic processing. It is this type of shop that sometimes causes problems for the electrical installer when it comes to estimating loads.

This exercise takes a bakery as a typical project. This electrical design may be adapted for similar conditions (cafe or apartment for example).

Building structure and finishes

General information about small bakery //

- Total floor area is 100 m2;

- Concrete floor, tiled throughout;

- Concrete soffit, exposed in bakery; suspended false ceiling in shop area;

- Walls, brick or building block. Fair-faced exposed in bakery; tiled or plastered in shop and toilets;

- Space heating by gas.

Let’s go through following sections on order to complete electrical design project. Note that there are few other sections left out for second part of this techncial article (which will be published in 2 days).

- Electrical design requirements

- Loading and diversity

- Lighting (electrical layout)

- Socket / Outlets (electrical layout)

- Other appliances (mixer, oven etc.)

- Phase balance

- Wiring systems

- Cost considerations

- Shop area

- Bakery area

- Temperature limits of 70°C and 90°C

- Final selection of of cable sizes

- Bakery wiring

1. Electrical design requirements

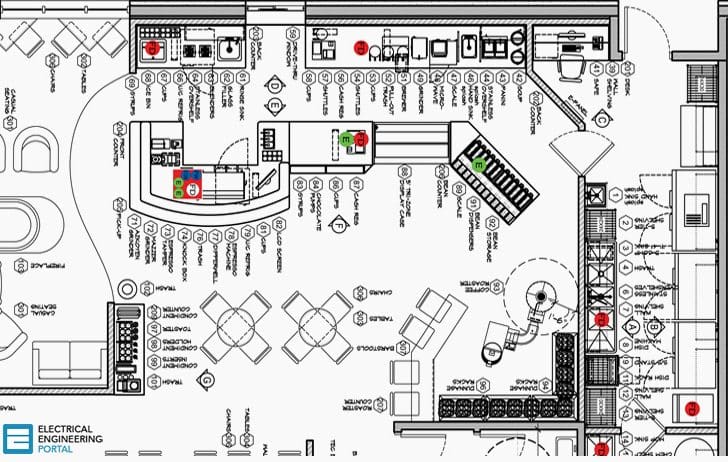

Proposed electrical layouts are shown in Figures 1 and 2. A full schedule of requirements is shown in Table 1.

It will be noted that space heating is by gas, although cooking is electric. This may not be realistic. In practice, a more likely situation would have gas cooking and heating. However, many catering establishments do have mixed services and in this case the electric cooking has been chosen in order to calculate diversity. A suitable Project Specification is shown in Figure 3.

2. Loading and diversity

It will be seen that the assessment of maximum demand is very much a matter of experience. There is a tendency to overestimate high fixed loads, which in practice only occur for short periods of time. Thermostats and energy regulators switch heater elements on and off at irregular intervals.

Lighting layout //

Information is required to determine the size of mains supply. If there is any doubt, it is worth showing diversity figures to the supply company.

IET Guidance Note 1, Selection and Erection, gives some advice about loading diversity. The figures used here have been taken from Guidance Note 1, but every electrical design project must be considered separately to take into account special factors. This is not an accurate exercise and all figures have been rounded off.

This installation will of necessity be a three-phase load, and maximum current per phase is the important calculation.

Power outlets layout //

3. Lighting

An allowance of 90% diversity is acceptable. For current loading calculations, fluorescent lamp ratings must be multiplied by 1.8 to take into account control gear losses. An assumption of 100 W per outlet is made for tungsten lamps, regardless of the specification lamp size. For convenience, the bakery shop lighting is spread over two circuits:

1. Shop lighting load //

= 10 x 58 W x 1.8

= 1044 W

at 90% diversity (1044 x 90%) / 230 = 4.1 A

Table 1 – Provisional electrical schedule

| Shop // | Bakery // |

| Lighting | |

| 10 x 57 W | 8 x 58 W |

| 4 x 60 W | |

| Twin 13 A sockets | |

| Display units 2 | Freezer 1 |

| Microwave oven 1 | Refrigerator 1 |

| Freezers 2 | Small mixers 2 |

| General purpose 6 | General purpose 4 |

| Other loads | |

| 3-phase mixer, 750 W | |

| Oven 10 KW | |

| Hob unit, 4 x 1.5 kW | |

2. Bakery lighting load //

= (8 x 58 W x 1.8) + (3 x 100)

= 1135 W

at 90% diversity (1135 W x 90%) / 230 V = 4.5 A

NOTE // 1.8 is a factor, which may or may not need to be applied to all types of fluoroscent fittings. If in doubt, consult the manufacturer of the luminaire(s).

4. Socket-outlets

Three circuits would be appropriate. It has sometimes been taught that it is custom and practice to put all sockets on one phase, but there is no requirement for this in the Wiring Regulations. However, at this stage, phase balancing has yet to be considered. Diversity allowances are 100% of first circuit and 40% for all others:

32 + 13 + 13 = 58 A

= 19.3 A per circuit

Note that this figure is for total load calculations only, not circuit cable sizing.

Project specification for shop //

5. Other appliances

Mixer, at 50% diversity:

750 W x 50% / 230 V x 3 = 0.55 A per phase

Oven, at 100% diversity:

10 x 1000 W / 230 V = 43.5 A

Hob unit, at 80% diversity:

6 x 1000 W x 0.8 / 230 V = 21 A

6. Phase balance

For electrical design, it is essential to balance loads across three phases as far as possible. This exercise should consider the diversified current demands to obtain a balance under normal working conditions.

Table 2 below gives an arrangement, which in the circumstances is reasonable but not a good balance. Note that at this stage, this does not necessarily indicate final distribution board particulars; although it may be better to put ring circuits on different phases.

7. Wiring systems

This project is interesting in that, at this early stage, some consideration must be given to the type of wiring systems appropriate to the two main areas, shop and bakery. This is one subject upon which the landlord or insurer may have an interest.

Table 2 – Arrangement of loads taking diversity into account

| Phase | Circuit | Amps |

| Brown // Phase 1 | Sockets | 58 |

| Mixer | 0.55 | |

| 58.55 | ||

| Black // Phase 2 | Lights | 8.6 |

| Hob | 21 | |

| Mixer | 0.55 | |

| 30.15 | ||

| Grey // Phase 3 | Oven | 43.5 |

| Mixer | 0.55 | |

| 44.05 |

8. Start by considering cost

From the financial viewpoint it is sensible to consider the most economical wiring system that the Wiring Regulations will permit. This is the starting point for design. Changes to more sophisticated methods may be introduced as the situation dictates.

Undoubtedly twin and earth cable is the easiest and cheapest system to install, but the outer sheathing gives only limited mechanical protection.

In the case of the shop, a certain amount of physical maltreatment should be anticipated and considered during the design and specification stages.

9. Shop area

Shop area must fulfill the following requirements //

- The public have access and must not be put at risk by their own activities.

- Children will be present and inquisitive fingers can cause damage.

- The shop staff may be heavy-handed in cleaning or careless when handling trays of stock. This food shop is subject to hygiene standards, which may include frequent washing down.

It is acceptable to install flat twin and earth cables under plaster or within building voids, provided the concealed cables are installed within prescribed zones.

10. Bakery area

Different parts of the bakery area are subject to differing conditions //

- Some general physical abuse can be expected.

- High temperatures will occur in close proximity to the oven and hob units. Wall surfaces may be frequently washed down.

In these circumstances, the choice of surface wiring systems should be one or more of //

- Steel conduit and trunking;

- Plastic conduit and trunking;

- Mineral insulated, copper-sheathed cable (MICS) with thermoplastic (PVC) outer sheath;

- Steel wire armoured PVC or thermosetting insulated cable.

11. Temperature limits

70°C

A point of interest is that wherever general purpose PVC cable is used, the recommended limiting temperature is 70°C. This will apply to all the systems listed in Bakery area, including the MICS with PVC outer sheath. Therefore, none has any working temperature advantage.

The Regulations show 70°C as the limiting temperature for accessible parts of metallic enclosures for electrical equipment. An air temperature in excess of 70°C will only be found in the oven or above a hob unit. There would appear to be no problem of cable selection on the basis of temperature alone.

90°C

If a higher temperature rating is considered to be important, the use of 90°C thermosetting (XLPE) cable may be possible. This insulation is available on single-core conduit cable. Care should be taken with armoured cable with XLPE insulation. Off-the-shelf supplies will probably have PVC sheathing.

It should be appreciated that conductors intended to operate at a temperature exceeding 70°C in normal service must not be connected to switchgear, protective devices, accessories or other types of equipment, unless the manufacturer of the equipment has confirmed that the equipment is suitable for such conditions.

12. Final selection and cable sizes

Having taken all factors into account, the final selection of wiring systems on this project can be made, and are shown in Table 3. It should be noted that cable sizes are based upon the scheme as illustrated:

- 0.35 V maximum earth loop impedance;

- Maximum voltage drop of 3% for lighting circuits and 5% for other circuits;

- Type B miniature circuit-breakers (MCBs).

13. Bakery wiring (cable, trunking and conduit)

Cable:

70°C PVC-insulated – Ref. 6491X, single-core cables;

Table 3 – Proposed cable sizes

| Circuit | Full load (A) | CB (A) | Size (mm2) |

| Bakery lights in conduit and trunking | 4.7 | 6 | 1.0 |

| 1.5 | |||

| Shop lights, surface or embedded in plaster | 4.3 | 6 | 1.0 |

| 1.5 | |||

| Bakery sockets, ring in conduit and trunking | – | 32 | 2.5 |

| Shop sockets, ring, surface or embedded in plaster | – | 32 | 2.5 |

| Mixer 3-phase, in conduit and trunking | 3.2 | 6 | 1.0 |

| Hob, in conduit and trunking | 25 | 32 | 6.0 |

| Oven, in conduit and trunking | 42 | 50 | 10.0 |

Steel or PVC trunking:

Main distribution from distribution board at high level to avoid any heat from appliances;

Heavy gauge PVC conduit:

- Drops to outlets at worktop mounting height; 2. Ceiling mounted exposed to luminaires.

- As an alternative, and to make cleaning easier, PVC mini-trunking could be used for wall drops.

Will be continued soon..

Reference // Electrical installation designs – B. Atkinson (Purchase hardcopy at Amazon)

Thanks,Very nice topic.

Hi

I’m currently working on a project for college. Would you mind answering some of

My questions.

Hi there, Can you give me the concept supplying power sources above from ceiling? I’m having difficulties cleaning my working place with wall mounted power supply, and my working area is 30×60 ft. for production . I’m hoping support soon .

One of the best website to study electrical engineering. keep it up and thanks for this gem EDVARD.

One of the best ELECTRICAL ENGINEERING learning website. It has covered so many courses and topics that one dont even need to got University and attend lectures (just frankly speaking). BTW keep it up and thanks for this GEM EDVARD.

I am wondering how can I get a two-page bakery machine for business purpose?

Thanks

Abebaw

Edvard, I have been hands-on for 55 years, busy in the HEAVY ELECTRICAL INDUSTRY, and I would like to COMPLEMENT YOU on a UNIQUE AND COMPREHENSIVE PORTAL. I have been following your program for a long time and every new portal has the BEST information available, each and every ELECTRICIAN & ENGINEER can use your information and have SUCCESS in implementing your advice, THANKS FOR YOUR DILIGENCE & COMMITMENT.

BEST REGARDS.

Thank you very much Pieter, that’s very kind of you. I do my best :)

tHIS IS NICE SITE, I WANT TO SEE MORE HOW AND THE DATA BASE APPROCH

Nice work! Anyway, some things might be wrong/odd regard legislation available in some countries:

A minimum section can be required. By example, lighting must have 1.5 mm2, outlets 2.5mm2 and force circuitry 1.5 mm2 as minimum wire section.

More, some countries impose a Schuko outlet for 230V, as primary protection. And a additional protection, with a RCBB (or RCBO) having Idn=30mA (max). A bakery its a commercial space, so another 300 mA general RCCB its required (type S).

For outlets circuits maximum installed power its 2.0 kW. Some normatives impose a maximum 24A on Fy2.5; 32A it is far to more. More, an outlet have a 16A max current, so 16A CB or RCBO its more than ok. Next, a CB protect circuit, no loads. So, for all lighting circuits, a 10A CB its ok. Some time 6A CB its more expensive.

Out of topic, in some way: lights are resulting from calculation. Free software do this and result its type of luminaire, power, position etc.

Please CatalinB,can you tell me,which software that you mention above,do this calculation and give the result of types of luminaire,power,position etc.?If you dont worry,i would appriciate a lot if you can suggest this type of softwares.Thank you

Simple & yet interesting. Nice refresher. Keep it up !!!