Electrical Safety

How can one stay safe and alive while working in a power system? That’s a good question; however, there are a dozen answers. But let’s start with the first answer. The primary concerns about electrical safety are the unseen nature of hazardous circumstances and the element of surprise. To build confidence when working around electricity, one must anticipate, imagine, and plan for the unexpected, as well as adhere to all required safety procedures.

Even those with experience in electrical safety must respect and prepare for the unexpected.

There are different approaches and personal protection equipment available to provide safe working conditions around and with electrical equipment. This technical article explains the most widespread approaches and safety equipment.

The theories underlying these approaches are also examined. Having a solid understanding of electrical safety concepts is critical for recognizing and avoiding potential hazards.

1. Thumb Rules for Personal Protection

Personal protection entails wearing of appropriate clothing, insulating rubber equipment, or other safety equipment to protect an individual from electrical shock. Another method of personal protection involves the implementation of equipotential principles, ensuring that all objects in touch are at the same electrical potential.

The presence of equipotential prevents electrical current from flowing. Utilizing insulating personal protective equipment or operating within an equipotential zone are established approaches for ensuring electrical safety.

1.1 Human Vulnerability to Electrical Current

Prior to delving into personal protection, it is beneficial to comprehend human susceptibility to electrical current. The magnitude of current traversing the body dictates the severity of the condition.

The emphasis is on current flow through the body rather than voltage. Indeed, an individual may come into contact with a voltage and suffer a shock; nonetheless, it is the current passing through the body that induces health complications.

According to tests conducted earlier, the threshold of sensitivity for current flow through the human body is thought to be between 1 and 2 mA (0.001 and 0.002 A).

The home ground fault circuit interrupter (GFCI), similar to those utilized in bathrooms, disconnects the circuit when the differential current approaches roughly 5.0 mA (0.005 A). The GFCI interrupts the circuit before hazardous current levels can pass through the human body.

The conclusion is that people are highly susceptible to relatively little electrical currents.

Figure 1 – Electrical engineer wearing insulating rubber gloves

1.2 Principles of “Isolation” Safety

Individuals can be safeguarded against electrical risks by utilizing appropriate rubber insulation goods, including gloves, footwear, blankets, and mats. Appropriate rubber products enable an individual to be insulated from hazardous touch and step potentials.

Touch and step potentials are elaborated in this technical article.

Electric utilities routinely test their rubber equipment to ensure safe working conditions. Hot-energized-line maintenance of the rubber glove is often conducted solely at distribution voltage levels. Figure 2 illustrates the cotton inner liners, insulated rubber gloves, and leather protection gloves employed in standard live-line maintenance.

Compliance with these rigorous safety regulations and equipment-testing protocols ensures worker safety. Moreover, electric utilities allocate substantial effort to train employees in safe practices, particularly with live-line operations.

Figure 2 – Insulating rubber gloves

Figure 3 – Substation engineer wearing insulated boots

Figure 4 – Substation engineers installing rubber mats

Figure 5 – Maintenance personnel using insulating rubber blanket for working on a circuit breaker

1.3 Principles of “Equipotential” Safety

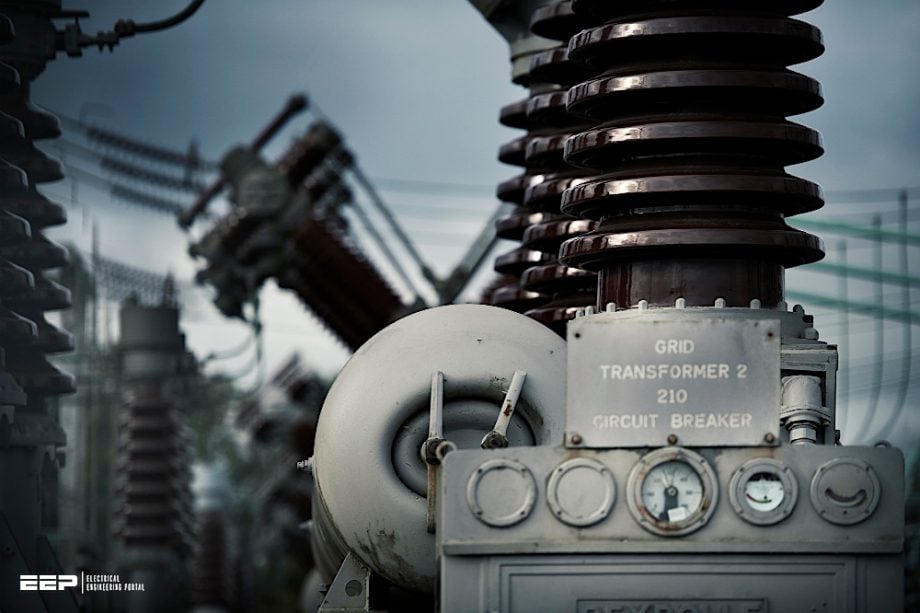

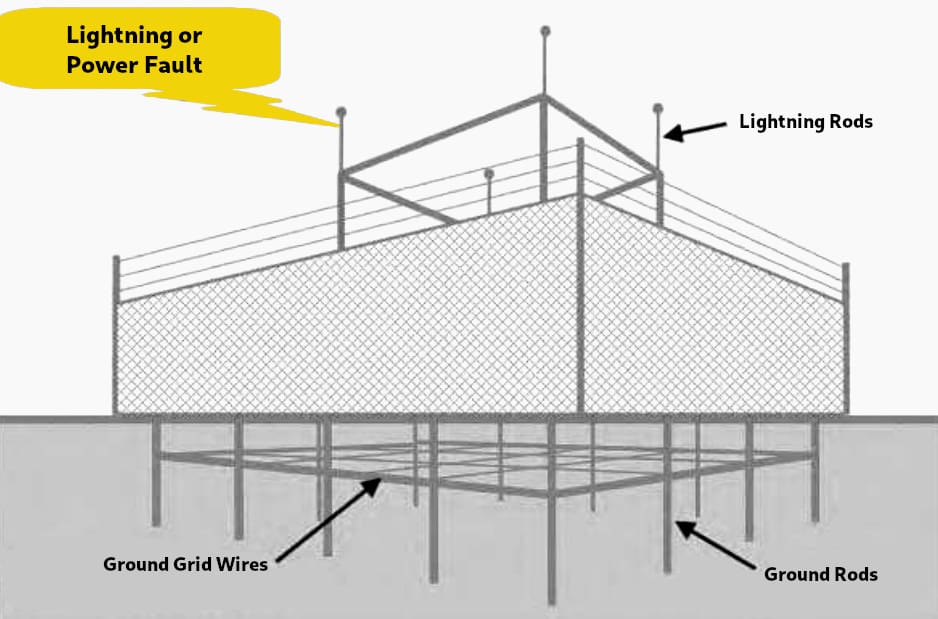

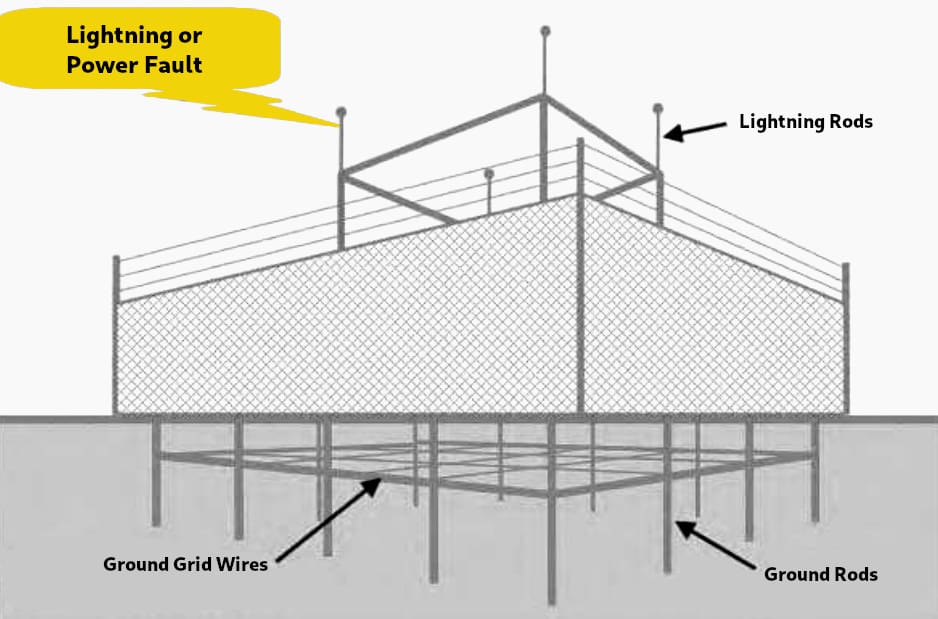

Substations are usually designed using a lot of ground rods and bare copper wires that are joined and buried between 45 and 70 centimeters below the surface. Metal fences, large equipment tanks, structural steel, and all other metallic objects necessitating an electrical ground reference are interconnected with the subterranean copper conductors.

This complex network of conductive metals constitutes the station ground grid.

Figure 6 shows the ground grid concept.

Figure 6 – Substation ground grids

Having an efficient grounding system is important for two key reasons. Initially, to establish a reliable ground pathway for fault current to return to the source, facilitating the tripping of circuit breakers for system protection. Secondly, effective grounding establishes an equipotential zone for secure working scenarios, ensuring human protection.

The equipotential zone reduces the likelihood of an individual encountering current flow during a lightning strike or electrical fault. In theory, all objects within an equipotential zone have the same voltage, resulting in the absence of current flow.

For instance, imagine you are aboard an aircraft at an altitude of 6,000 kilometers above the Earth. All conditions within the aircraft appear to be standard. This holds true in a well-designed substation.

1.4 Ground Potential Rise (GPR)

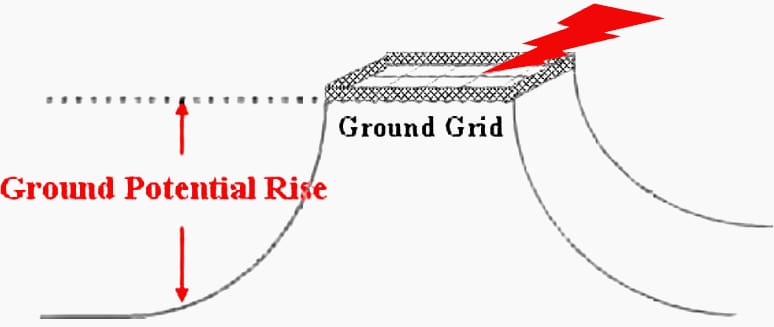

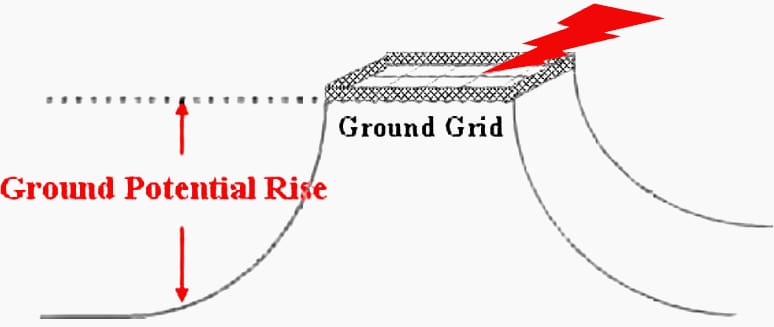

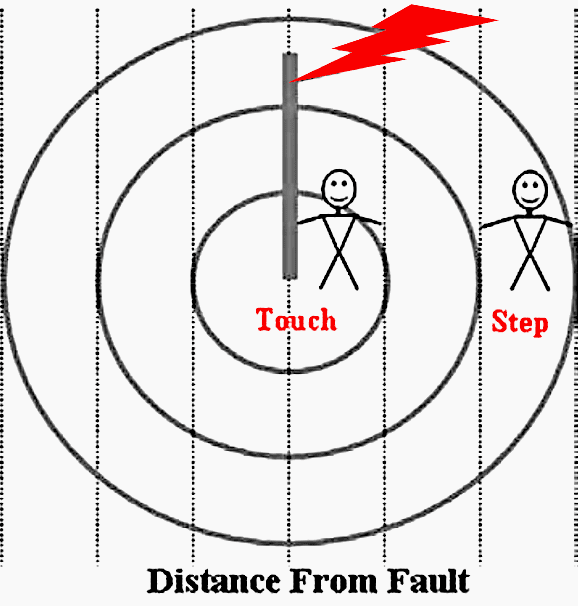

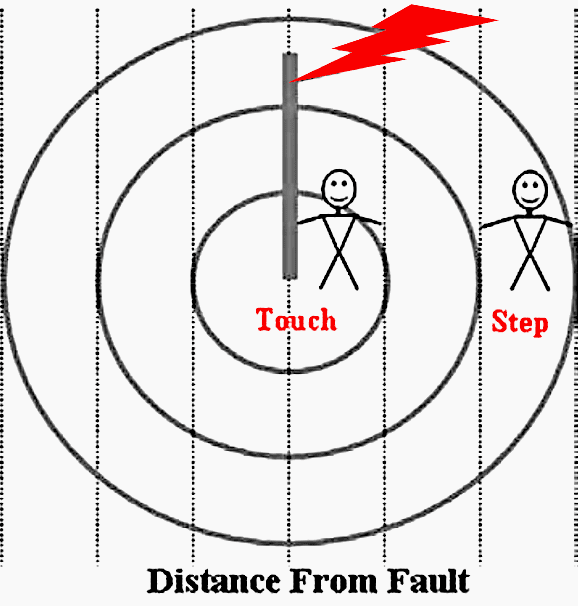

When a fault occurs in a power system, a ground potential rise (GPR) condition follows, wherein high electrical currents pass the ground soils, generating a voltage profile on the Earth’s surface. The voltage profile diminishes dramatically from the fault point, as illustrated in Figures 7 and 8.

This GPR condition may result in hazardous touch and step potentials.

Figure 7 – Substation ground potential rise

Figure 8 – Touch and step around structures

1.5 Touch and Step Potentials

In the case of a lightning strike or power outage at a substation, the entire facility rises to a high potential, ensuring that those on the ground grid feel no touch or step potential due to equipotential grounding. Touch potential is the difference between the voltage magnitude of an individual (or animal) in contact with an object and the voltage magnitude at the individual’s feet.

Touch potential may also refer to the voltage difference between two potentials (e.g., hand to hand).

Step potential refers to the voltage differential between an individual’s (or animal’s) foot. Footwear, gloves, and other garments provide insulation against touch and step potentials.

Rubber safety devices that are approved, tested, and correctly utilized offer protection against potentially dangerous contact and step potentials.

Further Study – Practical steps in the design of a substation grounding

1.6 Working on Transmission Lines Safely

Construction and maintenance teams operate on power lines in both energized and de-powered states. In either case, specific safety measures are obligatory. All precautions are founded on the fundamental concepts of complete isolation or the establishment of an equipotential zone.

One must prepare for the scenario of a deenergized line becoming energized unexpectedly. Below are examples of various methods for safely working on electrical lines.

1.6.1 Working With Energized Equipment

Several methods exist for the safe maintenance of energized power lines, including insulated bucket trucks, hot sticks, and bare-hand live-line techniques.

Insulated bucket trucks: Utilizing insulated bucket trucks facilitates operations on both powered and deenergized lines. Depending on the system voltage, rubber gloves, fiberglass hot sticks, or live-line bare-hand techniques may be employed safely while operating from these maintenance vehicles.

Figure 9 shows using an insulated buckets truck.

Figure 9 – Insulated buckets truck

Hot-stick, live-line maintenance: Work may be conducted on energized lines utilizing hot sticks. Figure 9 depicts workers utilizing fiberglass hot sticks for maintenance tasks.

Barehand live-line maintenance: An individual may wear a conductive suit and safely contact live transmission voltages, as seen in Figure 10, provided they avoid contact with grounded objects. This resembles a bird perched on a wire. The conductive suit creates an equipotential zone, so preventing current flowing within the suit or the human body.

As all objects the individual touches are at a same potential, no current passes the body, ensuring the individual is protected from electrical shock.

Figure 10 – Live maintenance on transmission lines

1.6.2 Working With Deenergized and Grounded Equipment

In deenergized scenarios, personnel use ground jumpers to prevent hazardous potentials in the event of accidental line energization.

Grounding equipment fulfills two functions:

Function #1 – Grounding creates a secure zone of equipotential, akin to that seen in substations. It offers a secure setting against “touch potentials“.

Watch Video – Bare-Hand, Hot-Line/Hand work directly on 220kV Live Power Line

Function #2 – Grounding makes circuit breakers trip more quickly in the event that the line is inadvertently activated.

Figure 11 illustrates multiple jumpers used on a power line

Figure 11 – Ground jumpers used for maintenance of transmission lines

1.7 Working Distribution Lines Safely

Like transmission line crews, distribution line crews operate under both energized and deenergized conditions. Mandatory special safety procedures are required in both scenarios. Distribution line operators operate energized lines (often under 34 kV) utilizing rubber isolation equipment (such as rubber gloves and hot sticks) for voltages below 34 kV.

Figure 12 illustrates live line maintenance operations on distribution systems. Deenergized line operations necessitate the use of “ground jumpers,” as previously mentioned.

Figure 12 – Live maintenance of a distribution line

1.8 Switching

Switching refers to the changing of an electrical system’s configuration or the implementation of isolation for secure operational activities. Switching is necessary to operate disconnect switches, circuit breakers, and for scheduled maintenance, emergency restoration, load transfer, and equipment isolation.

Figure 13 illustrates a switching occurrence within a powered substation. Switching necessitates meticulous management of all persons and equipment engaged. This typically necessitates continuous radio, telephone, or visual connection for safety assurance. Comprehensive radio and equipment labeling protocols are necessary to mitigate interference with work activities.

The process of switching can be exceedingly time-intensive owing to the repetitive communication involved in the switching instructions.

Figure 13 – Live maintenance substations.

1.9 Electrical Safety around the Home

Home safety include the understanding of touch and step potentials. Regardless of exposure to hazardous touch or step potential in a substation or residential setting, identical conditions rule, necessitating same security measures. When the insulation surrounding energized wires is breached, hazardous step and touch potentials may arise, even in home environments.

Worn extension cords might have exposed conductors, posing 120 V AC or 230 V AC touch potential risks. All damaged cords must be repaired or changed. Moreover, water, dampness, metallic objects, and faulty devices all exacerbate the risk of damage from inadvertent contact.

Following technical article discuss the presence of electrical safety issues in residential settings.

Read more – Inspection of electrical installations in home

References: Electric Power System Basics