The great majority of the energy used within a hospital is purchased from outside in the form of natural gas and electricity. A small proportion is bought in as diesel oil. The energy bought in is converted by a number of conversion systems into the most important internal flows of energy, namely heat, cold, electricity and compressed air.

These energy flows are used for among others the following applications:

Heat

Heat is used in the form of steam and in the form of hot water. Steam is used for among others the kitchens, humidification in HVAC and sterilisation. In addition steam is used to transport heat over longer distances. Hot water is used in the form of central heating and tap water. In many cases heat is transported from the heat generating station in the form of steam and then converted locally into central heating or hot tap water.

Gas-fired boilers or cogeneration systems generate the heat.

Electricity

Electricity is used for a wide variety of purposes. The largest electricity consumers in a hospital are lighting, cooling machines, air compressors, circulation pumps, HVAC fans, medical equipment and office equipment.

Compressed Air

Compressed air can be divided into two main categories, namely medical and technical air. Medical compressed air refers to direct treatment and care of patients. Examples include breathing apparatus and surgical tools driven by compressed air. Medical compressed air is subject to very high standards for availability and quality.

Other compressed air that is not directly related to patients falls under the heading of technical compressed air. Examples include HVAC control systems, workshop applications or keeping containers under pressure.

Cold

Cold mainly takes the form of ice water and is used for the great majority in climate control systems, for cooling and drying the ventilation air.

In many cases cold is generated centrally by means of compression coolers. In combination with cogeneration, absorption-cooling machines are used to supplement compression coolers. The breakdown of the energy flows just mentioned is shown in fig. 1 below.

Figure 1 shows that heating and lighting account for a large part of the energy consumption. Cooling and hot tap water each represent around 5% of the energy consumption. Electricity consumption by medical and office equipment falls into the “Other” category.

Benchmarking on the basis of energy consumption

The healthcare sector is one in which a lot of information is generally available concerning energy consumption. This offers many opportunities for energy benchmarking, i.e. comparing the energy consumption of different hospitals. The parameter used for comparison in benchmarking is very important.

The two techniques most commonly used for benchmarking are the energy consumption per square meter or per bed. With regard to these techniques it is important to bear in mind that they are based on technical characteristics of the building. If sufficient data are available then it is desirable to compare hospitals on the basis of energy consumption both per bed and per square meter. One difficulty that stands in the way of benchmarking is the degree of outsourcing in the hospital: some hospitals contract out e.g. their catering or laundry activities, which off course leads to a lower energy consumption by the hospital itself.

A good example is provided by a medium-sized hospital for which a benchmarking study was carried out. The hospital was first compared on the basis of energy consumption per square meter, from which it turned out that from this point of view the energy consumption was higher than the average. From this it might be concluded that the hospital was underperforming.

However, a second comparison on the basis of energy consumption per bed showed that the hospital performed better than average.

The critical factor here is of course the number of square metres per bed. This factor is determined by the type of hospital and by the design criteria for its construction. We also have to take into account the trend towards higher quality of care and greater privacy for patients, which leads to a lower number of beds per room and thus a greater number of square metres per bed.

- In many countries the number of beds is taken as the basis for subsidies, so that sometimes we find highly creative ways of defining this parameter.

- When taking the number of square meters into consideration we have to decide which areas are included in the benchmark or not (e.g. car parks, corridors and equipment floors).

Another method of benchmarking is the one used in process industries, namely benchmarking on the basis of “production” by the hospital. The measure used for production may be the number of overnights or the number of bed-days. From this we can determine the energy consumption per overnight. However, this depends to a large degree on the type of hospital, and on trends in healthcare.

For example, the number of overnights per treatment has fallen sharply in recent years, so that the number of treatments has risen considerably for the same number of beds.

Taking all these advantages and disadvantages into consideration, most authorities opt for benchmarking on the basis of the number of square metres, only with a distinction being made between teaching hospitals and local hospitals. On the basis of sector studies, energy studies and data from research institutes, the average values for western Europe are as shown in Table 1:

| Gas | Electricity | |

| Energy consumption per m² | 262 MWh/m2/year | 113 MWh/m2/year |

| Energy consumption per bed | 25 235 MWh/m2/year | 10 944 MWh/m2/year |

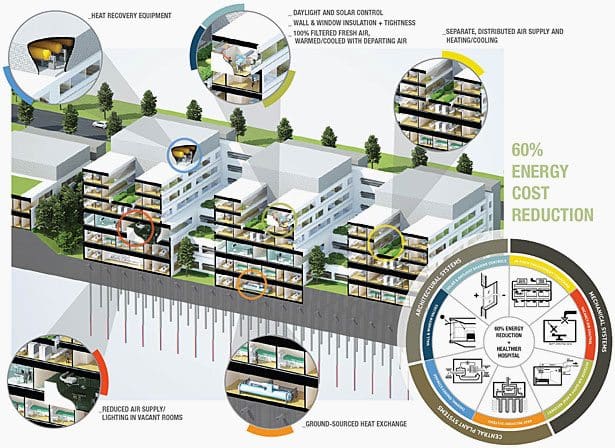

renewable energy helps to cut down the energy bills in a long run. Other methods including energy-efficient equipment, LED lights, help in making hospitals more energy efficient