Turnkey Substation Project

Behind the successful execution of a turnkey substation project is always successful project management. Young engineers working on the execution of substation projects often repeat the same mistakes that often lead to unforeseen project costs. Generally speaking, management of turnkey projects can be described as monitoring and checking of various items and activities in a turnkey project based on the contract document and specification.

These include monitoring and checking of project schedule, contract scope of work and specification, Variations, Additional Work and Claims, project safety, quality assurance, solving potential difficulties and trouble, and labour, environmental and site condition.

A good project management plan would contain standard procedures and guidelines such that the monitoring and checking of the above items could be planned and executed systematically.

- Objectives in Execution of a Substation Project

- Time Schedule with Identified Key Milestones

- Project Execution – Engineering

- Handling Claims

- Testing and Acceptance Challenges

- Set Up Project File (SLD, Equipment, Drawings, etc.)

- Project Test Summary

- Acceptance Standard for a Turnkey Substation and Equipment/Works

- Acceptance Tests Scheduling

- Training Of Maintenance Personnel

- Deficiencies and Problem Resolution

- Avoiding Environmental Incidents

- Commissioning Notice To Energize

- BONUS (PDF) 🔗 Download ‘A Guide to System Operations in Modern Electric Power Grids’

1. Objectives in Execution of a Substation Project

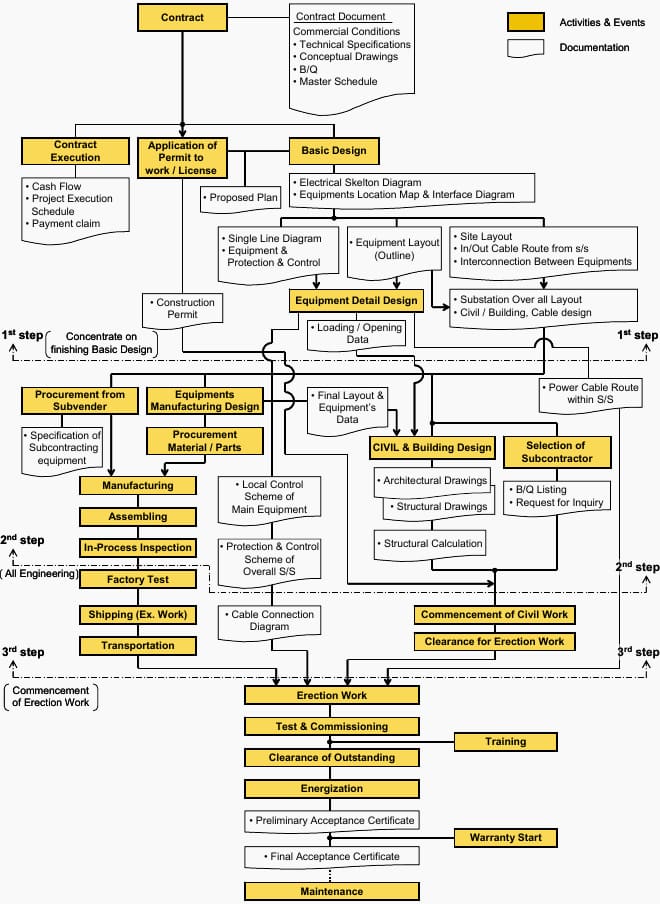

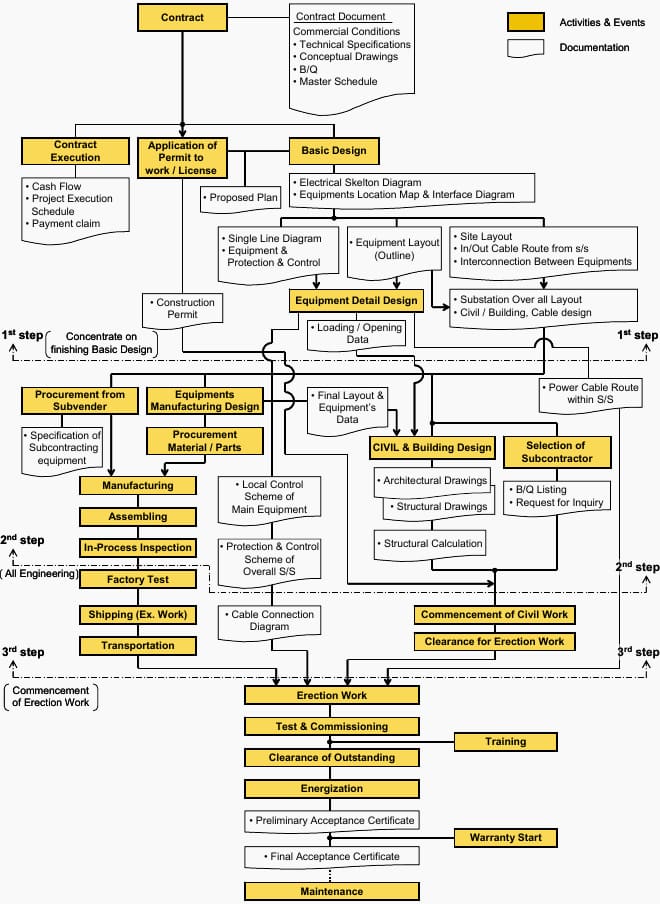

The successful execution of a substation project depends on the careful definition and establishment of numerous goals. Turnkey project execution is illustrated in Figure 1 by a flowchart that includes some common processes and objectives.

Among the most crucial parts of carrying out a project is striking a balance between critical path management and the following:

- Flow of work should not be reversed. See Figure 2.

- Work execution should be matching with Time Schedule. See Figure 3.

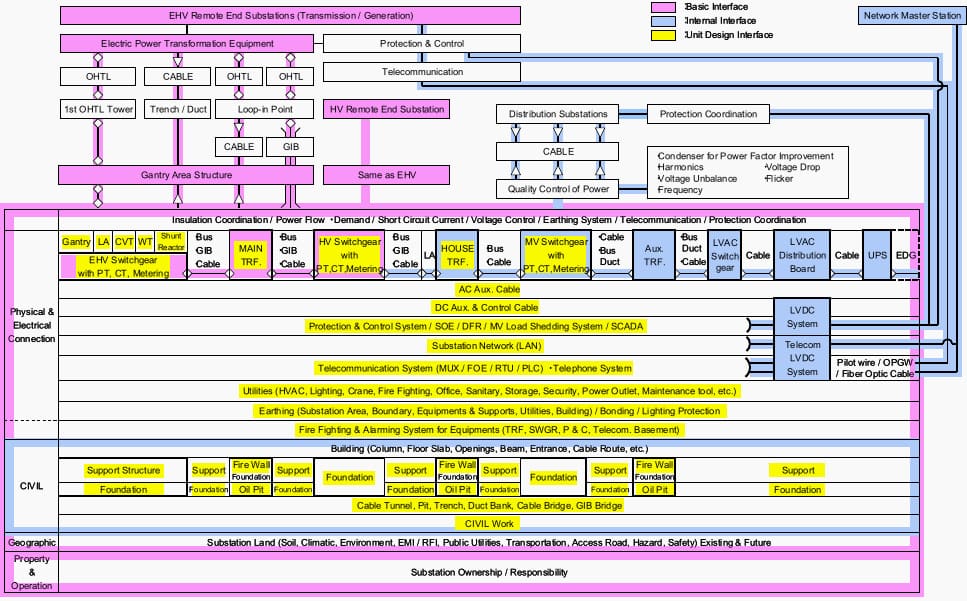

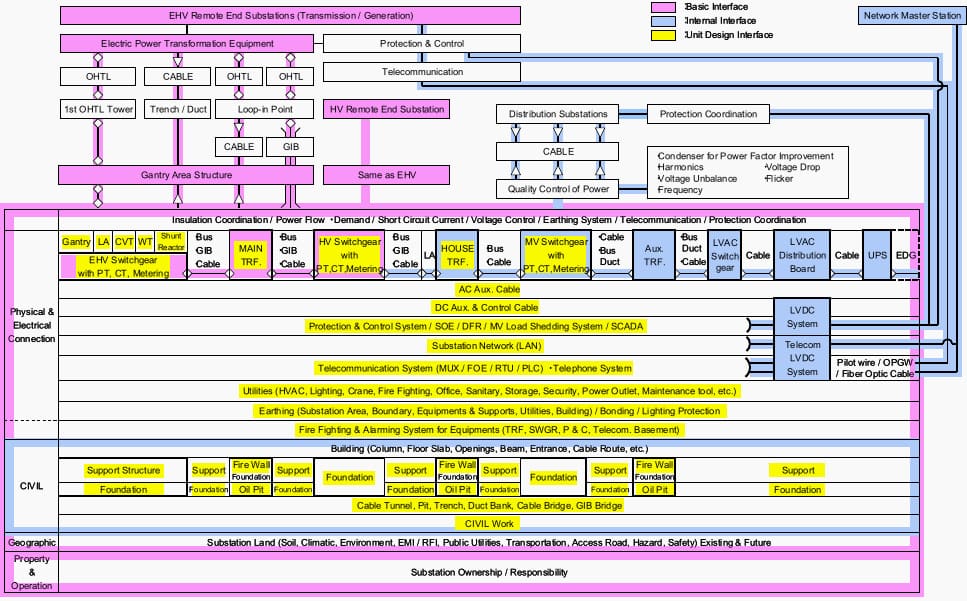

- Complete compliance with required interface engineering as substation package. See Figure 4.

A successful project management plan must address such discrepancies and misalignment of activities. The challenge in project execution is to consistently identify effective methods to reduce activity gaps and advance the project.

Figure 1 – Preparing equpment poles for installing on prepared foundations

Project management necessitates a clear comprehension, visualization, and assessment of potential impacts that may result from the misalignment of events concerning the aforementioned three key points. In these situations, the project’s success hinges on the capacity to assume leadership and realign the team’s efforts toward the most efficient trajectory.

If determining the effective path proves challenging, the prioritization of events should consistently follow the sequence of Flow, Time, and Engineering. In typical project scenarios, increased involvement of multiple parties complicates the smooth progression of the project, necessitating greater effort to align the objectives of the diverse stakeholders.

Figure 2 depicts the project execution workflow that will be undertaken following the awarding of the contract to the Service Provider. This flowchart demonstrates a genuine application utilized in an actual turnkey project.

The visual representation of a flowchart is crucial as it enables everyone involved to comprehend the project’s workflow effortlessly!

The implementation of a flowchart will encourage a unified and methodical approach among all parties involved in the execution of the project. An effective flowchart would outline all the essential processes encompassed in a turnkey project.

Figure 2 – An example of the turnkey substation project execution flow

Figure 2 illustrates flowchart wih many activities and events that constitute the total project execution. The execution of these activities and events is controlled and supported by documentation. The event “Application of Permit to Work/License” may be deemed complete with the issuance and receipt of the “Construction Permit” document.

By considering the aforementioned concept, we can comprehend the prospective issues in subsequent events when the prior events in the flowchart remain unfulfilled.

For instance:

Minor outstanding things may be addressed; however, critical items must be completed prior to advancing to the next phase.

What is the paramount consideration for advancing with the event? The documents and flowchart depicted in Figure 2 demonstrate a conventional approach to doing the work. The document depicted in the flowchart should comprehensively encapsulate all knowledge and expertise related to turnkey project execution. This documentation serves as a tool for designing activities and events at any level.

Analysis of the flowchart indicates that one must not only await the completion of pre-events but also prioritize items for the subsequent event to facilitate project progression.

We can recognize from the flowchart in Figure 2 that as the project moves forward, more and more events are executed in parallel. For example, if we look at the events after contract, there are three parallel events; i.e. “Contract Execution”, “Application of Permit to work / License”, “Basic Design”.

Once the overall layout of the substation has been developed, a minimum of four activities will be completed concurrently.

Thus, it is evident that the early procedures must be done accurately and flawlessly; failure to do so will result in worsened issues subsequently. In practice, all concurrent management must be meticulously managed prior to the commencement of installation operations.

Suggested Reading – Technical Documentation for a Turnkey Substation

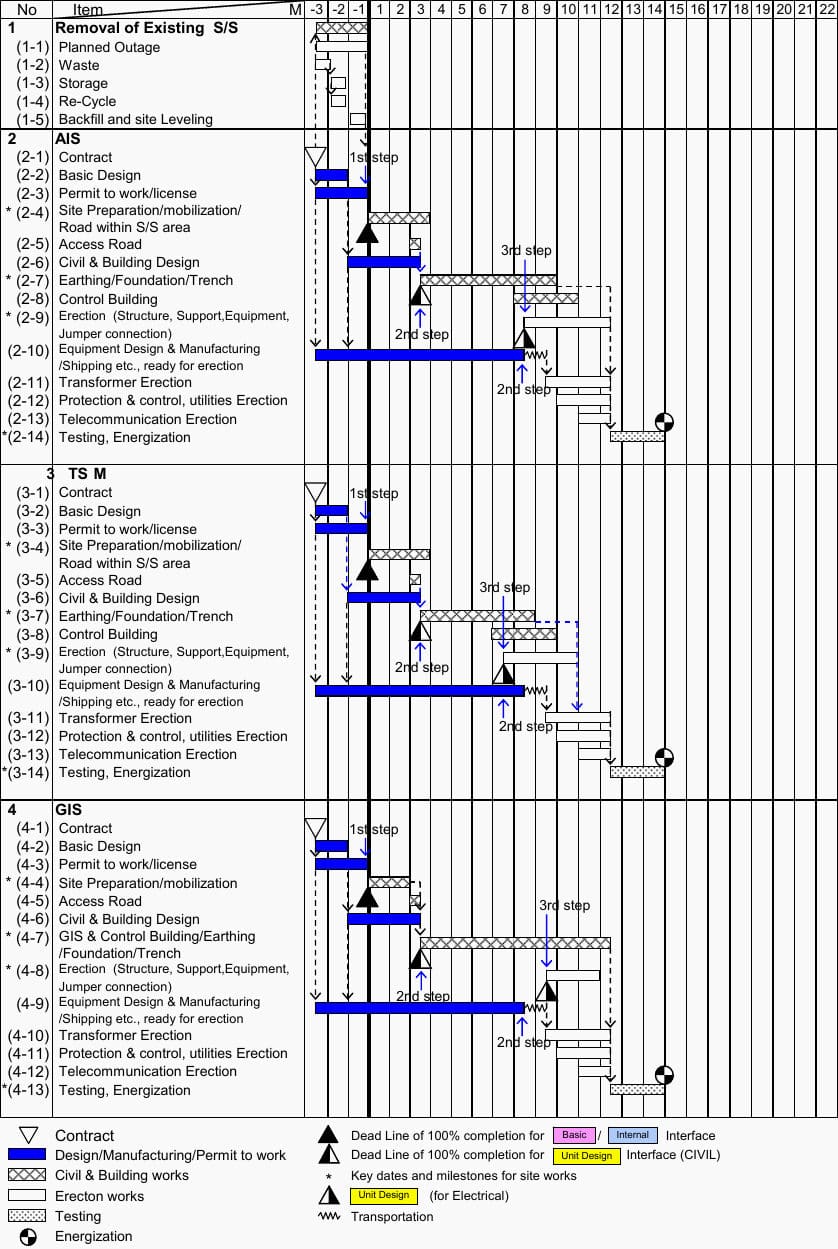

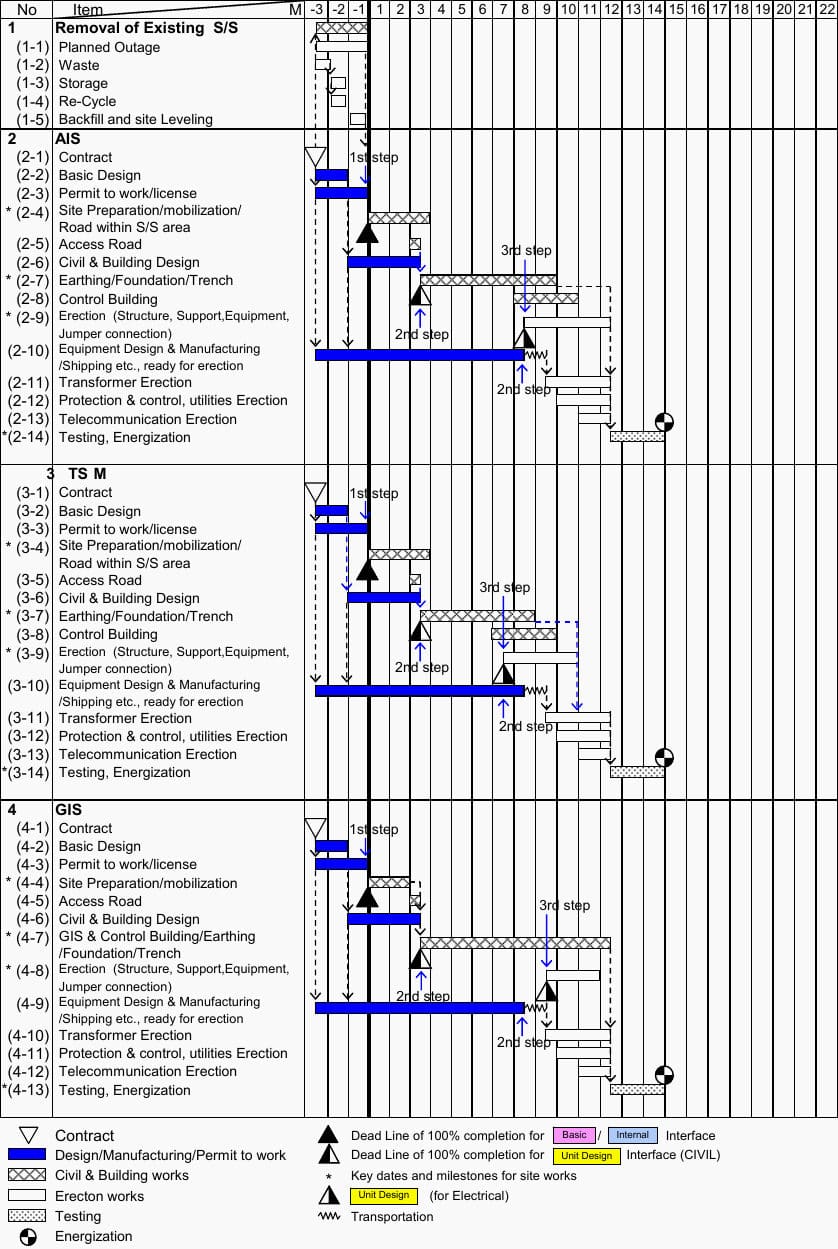

2. Time Schedule – Identified Key Milestones

A crucial instrument for project execution is a timeline that defines the principal milestones of the project. Figure 3 illustrates the standard timeline for the execution of site work for each type of substation project:

- Air-Insulated Substation (AIS)

- Gas-Insulated Substation (GIS)

- Combination of AIS and GIS substation (MTS)

- Removal of existing substation if required

It is generally accepted that there are four principal dates and milestones for site operations:

- Commencement of site preparation / mobilization

- Commencement of civil building / foundation works

- Commencement of erection (Installation of Structures and Equipments)

- Energization

Figure 3 – An example of time schedule for the Turnkey substation project

Ideally, the engineering of each phase should be finalized prior to commencing site preparation; unfortunately, this is challenging to accomplish in practice. Consequently, it is imperative to prioritize the engineering events to ensure the project’s seamless execution. The capacity to identify and prioritize events is the fundamental premise of project management.

The three actions depicted in Figure 2 must be executed sequentially in accordance with the Time Schedule presented in Figure 3.

Step #1 – Concentrate on finishing Basic Design which enable the two major teams (the equipment / civil & erection) to start their own job in parallel,

Step #2 – Prepare All Engineering for commencement of civil works including permission for construction and All Engineering for manufacturing equipment & delivery to site

Step #3 – Commencement of Erection Work

Following the third stage, the subsequent objective is the Substation Energization. However, it is crucial to acknowledge that the initial and subsequent steps are vital for comprehensive coordination and management. The successful completion of the initial and subsequent steps will positively influence the subsequent phases of the projects.

3. Project Execution – Engineering

Engineering is crucial in project execution to facilitate the seamless implementation of the project during the construction, installation, and testing phases. Errors committed or overlooked during the engineering phase can lead to complications in the subsequent stages of the project.

Consequently, to mitigate potential issues arising from engineering, project engineering operations must be organized systematically.

Figure 4 illustrates the necessary engineering activities for a standard turnkey substation installation. In accordance with the previously outlined Project Execution Flow and Time Schedule requirements, the prioritization of engineering tasks can be categorized as follows:

- Basic interface

- Internal interface

- Unit design interface

Figure 4 – Example of engineering interface for a typical turnkey substation project (click to zoom)

The basic interface and internal interface components specified below must be entirely finalized, with no outstanding items, prior to the initiation of site works. Illustrations include:

Basic interface:

- Substation Ownership / Responsibility

- Geographical location and soil data of S/S and Future developing plan of surrounding area

- System short circuit current at each voltage level

- Overall Single Line Diagram

- Main Busbar Configuration (Double-Bus, 1 1/2 CB, etc.)

- Auto Transfer Switching

- Electric Magnetic Compatibility / Radio Frequency Interface requirement

- Network Parameter (electric characteristics)

- Parameter / Length (Cable parameter / Length)

- Noise / Vibration limit at S/S Boundary

- Type of power substation (AIS, MTS, GIS)

- Future Extension Requirement

- Preliminary overall site layout matching with the orientation of Incoming and Outgoing feeder

- Diversion Plan of O/H (overhead) or U/G (underground) (Exchange of route and remote end substations to be linked)

- Remote end S/S (ex. Protection / Telecommunication) modification or replacement

- System Grounding method

- Typical Protection Scheme Diagram

- Fire Fighting requirement (Water, CO2, Inert gas etc.)

- Interface with outgoing feeder / Internal connection

- CT calculation and coordination

- Required Testing and Maintenance Space (such as HVAC test, Lifting space for OLTC inspection etc.)

- Allowable Maximum height and weight for transportation (specially for Power Transformer)