Cement plant applications

This technical article relies on the great paper written by Barton J. Sauer (Siemens Energy & Automation) which goes into essence of selecting the proper AC motor for cement plant applications.

Although motors may appear to be the least complicated component in the specification of cement mill equipment, this article shall try to demonstrate that cement plant applications present an immense matrix of application criteria to properly specify and design motors.

To obtain the correct motor for the specific job, communication, expectations and knowledge must be exchanged between the mill operator, driven equipment suppler and motor manufacturer.

Operating Conditions

Basic motor specifications begin with determining the motor nameplate hp and rpm. These are determined by the process equipment supplier and are based upon a steady state equipment operation.

Next is the determination of the available power voltage.

The cement plant operator, process equipment supplier or engineering consulting firm must determine the most effective power source, taking load hp and amp values of the entire system into consideration.

The Hz rating is determined by the power system available at the site. Because the cement market is global with many Hz and voltage combinations, the Hz value cannot be assumed. It is important to the motor manufacturer in the proper design of a motor, which would be different for Chile (50 Hz) than Argentina (60 Hz).

Ambient temperature is often overlooked as a design criteria.

Ambient temperatures below –30° C can require special bearing lubricant and material requirements. Conversely, ambient temperatures above 40° C may result in the allowable motor temperature rise to be lowered, which effectively de-rates the motor output.

The altitude at the site can also affect the motor selection when installation elevations exceed 1000 meters.

The lower density of air at higher altitudes results in a decreased cooling media for the motor. The derate factor is 1% of the specified temperature rise for each 100 meters of altitude in excess of 1000 meters.

Driven Equipment Torque Requirements

To properly select AC induction motors for any application, the speed vs. torque requirements of the driven equipment must be understood. It is an easy mistake to believe that a 400 hp 1200 rpm motor, which would function well in a low inertia fan application, would also work aptly in a kiln application.

However, the load torque requirements of a fan pump during initial starting are typically less than 30% of full load torque, while a full kiln could have load torque requirements of over 100% of full load torque.

The distinction must be understood between the running condition of the driven equipment, which dictate the hp and rpm of the motor, and the starting load condition of the driven equipment, which dictates the motor starting characteristics.

The National Electrical Manufactures Association (NEMA) classifies the torque characteristics of motors as follows:

// Locked-rotor Torque (LRT)

“The minimum torque which the motor will develop at rest…with rated voltage”, expressed as a percentage of rated full load torque the motor generates at initial rotation of motor shaft

// Pull-up Torque (PUT)

The lowest percentage of rated full load torque the motor generates during starting.

// Breakdown Torque (BDT)

The highest percentage of rated full load torque the motor generates prior to reaching full load speed.

A stall condition requires the mine operator to lower the starting load before attempting to restart the equipment. In the case of crushers or mills, this means the removal of aggregate from the machine. Excessive stall conditions also damage the motor due to excessive current flow in the stator and rotor.

Design Specs // Motor Enclosure

The motor enclosure defines the degree of protection for the motor windings. The selection of the motor enclosure is typically left to the discretion of parties other than the motor manufacturer.

However, the motor manufacturer can choose to provide an enclosure that exceeds the requirements of that specified by the purchaser.

1. Totally Enclosed Fin-Cooled Motor (TEFC)

Totally enclosed fan cooled is the most common enclosure for the cement industry.

A totally enclosed machine is one so enclosed as to prevent the free exchange of air between the inside and the outside of the case but not sufficiently enclosed to be termed air-tight.

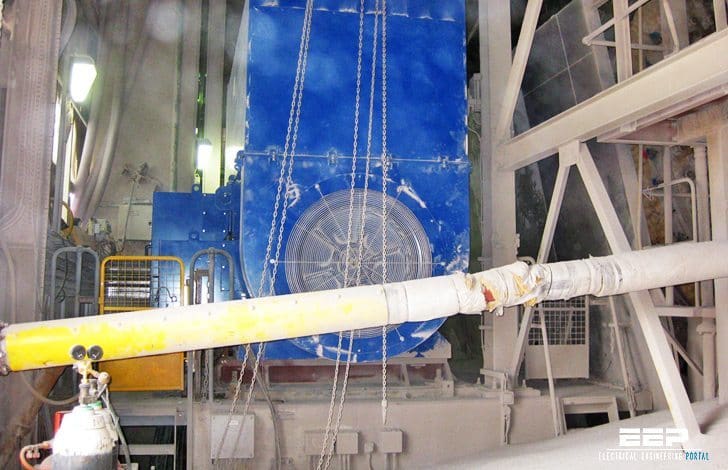

The two major types of TEFC motors are totally enclosed fin cooled and totally enclosed air to air cooled (TEAAC – Figure 1 above). The fin cooled (Figure 2) variant is defined by the cooling fins that cover the main structure of the enclosure.

Typically this frame is constructed of cast iron, although welded steel fin and aluminum cast construction is occasionally offered. TEAAC motors are equipped with an air to air heat exchanger on the top of the motor stator. In a TEAAC enclosure, the hot air from the stator is forced around the tubes that channel the cooling air.

Available tube materials on TEAAC motors include aluminum, copper and stainless steel, as appropriate for the environmental conditions.

Open Enclosures: Open type enclosures present a lower cost option to the mining industry, although as the NEMA definition implies, the degree of protection for the motor windings is diminished. “An open machine is one having ventilating openings which permit passage of external cooling air over and around the windings of the machine.”

The primary open type enclosures seen in the cement industry is the Weather Protected Type II (WPII – Figure 3).

The WPII enclosure includes a minimum of three 90º turns of the inlet and exhaust air to limit the ingression of airborne contaminants. The WPII type motor can also be supplied with filters on the air intake (galvanized steel or stainless steel are most common).

By allowing the ambient air to pass directly through the motor rotor and stator, the open enclosures cool the motor better allowing for more hp output than with a TEFC or TEAAC enclosure.

The primary limitation/disadvantage of the open enclosures is that airborne dusts that are in the cement environment can build up inside of enclosures and cause the units to overheat. In addition, the airborne contaminants can also tend to “sand blast” the stator winding insulation if filters are not in place.

2. Totally enclosed water-air-cooled motor (TEWAC)

”A totally enclosed water-air-cooled machine is a totally enclosed machine which is cooled by circulating air which, in turn, is cooled by circulating water. It is provided with a water-cooled heat exchanger, for cooling the internal air and a fan or fans, integral with the rotor shaft or separate for circulating the internal air”.

The TEWAC enclosure provides the advantage of the greater hp/stator weight of an open type motor with the protection of the stator via its “totally enclosed” characteristics.

This enclosure will provide the highest hp ratings of all enclosed motors, ratings unachievable or cost prohibitive on TEFC motors.

The obvious drawback of the TEWAC enclosure is its water requirements. The supply water must be pumped, cooled and retain a high level of cleanliness.

Cement production (VIDEO)

Reference: Selection of AC Induction Motors for Cement Plant Applications – Barton J. Sauer, Siemens Energy & Automation, Norwood, Ohio

thank you very best information

the article is good..but i Can’t download it in pdf format…There is no option like create pdf…

also create an EEP app for windows operated phone…

the article is good..but i Can’t download it in pdf format…There is no option like create pdf…