Experience in transformer maintenance

Let’s discuss the visual and mechanical inspection procedures for oil-filled power transformers. It’s important, very important to examine a variety of key checkpoints, both external and internal to transformers, all based on the IEC 60076 standard. Each item on the checklist contributes to a complete picture of a transformer’s condition, from the quality of its paint to the functionality of its auxiliary devices.

But first, let’s remind ourselves and our younger engineers why transformers are so important in a power system.

Power transformers play a pivotal role in the efficient and reliable distribution of electrical energy across various systems. These complex machines are responsible for stepping up or stepping down voltage levels, facilitating the transfer of electricity from generation points to consumption centers.

Ensuring the optimal performance and longevity of power transformers is not just a matter of necessity; it’s a requirement for maintaining a seamless power supply network.

In this article, we delve into the intricacies of visual inspection and mechanical checklists for oil-filled power transformers. Drawing from the IEC 60076 standard, we explore a range of critical checkpoints that cover both the exterior and interior aspects of transformers.

From assessing paint quality to evaluating the operation of auxiliary devices, each step in the checklist contributes to the holistic understanding of a transformer’s health.

The proactive approach advocated by these inspections not only enhances operational safety but also extends the transformer’s service life, thereby reducing downtime and minimizing operational disruptions.

Join us as we navigate through the systematic process of evaluating power transformers, step by step, ensuring that every element is meticulously examined. By the end of this article, you’ll have a clear grasp of the indispensable role played by visual inspections and mechanical checklists in the world of power transformers.

- Impact Analysis and Transit Checks in Oil-Filled Transformers

- Impact Recorder Empowerment: Strengthening Transformer Transport Reliability

- Nitrogen or Dry Air Pressure Check

- Transport Weight Reduction and Storage Considerations

- Advantages of Nitrogen and Dry Air Filling

- Critical Pressure Monitoring for Transformer Integrity

- Mitigating Moisture Intrusion: A Case Study

- Verification of Transformer Components During On-Site Assembly

- Check for quality of paint, lifting lugs, weld areas, rust spots and wheel stoppers

- Inspect the transformer nameplate information and accurate placement

- Comprehensive Bolt Tightness Inspection Using Torque Wrench Method

- Thoroughly Inspection of All Grounding Points for the Secure Connection

- Check Direction and Slope of the Buchholz Relay

- Maintaining Cooling Efficiency (Open Valves Between the Main Tank and…)

- A Case Study of Diagnosing and Rectifying Abnormal Transformer Behavior

- Check the HV, LV and TV (if applicable) bushings for damage and completeness

- Check for Correct Color and Quantity of Desiccant in Breathers

- Verify the Proper Configuration of Heaters and Humidity Meters in Local Control Cabinet

- Ensuring Harmonious Phase Marking

- Ensuring Safe and Effective Clearances for Live Components in Power Transformers

- Checking Proper Operation of Auxiliary Devices in Power Transformers

- Ensuring Accurate Labeling of Auxiliary Devices According to Approved Drawings

- BONUS! Power Transformer Maintenance and Application Guides (PDF)

1. Impact Analysis and Transit Checks

Understanding the Role of Impact Recorders in Oil-Filled Transformers

During the transportation and delivery of heavy machinery like oil-filled transformers, the risk of encountering external forces and mechanical shocks is significant. These forces can potentially cause structural damage and compromise the transformer’s integrity, leading to performance issues or even catastrophic failures.

To address this concern, impact analysis and transit checks play a crucial role in ensuring that the transformer arrives at its destination unharmed and ready for operation.

The recorder consists of a sensor capable of detecting various types of mechanical forces, including vibrations, shocks, and impacts.

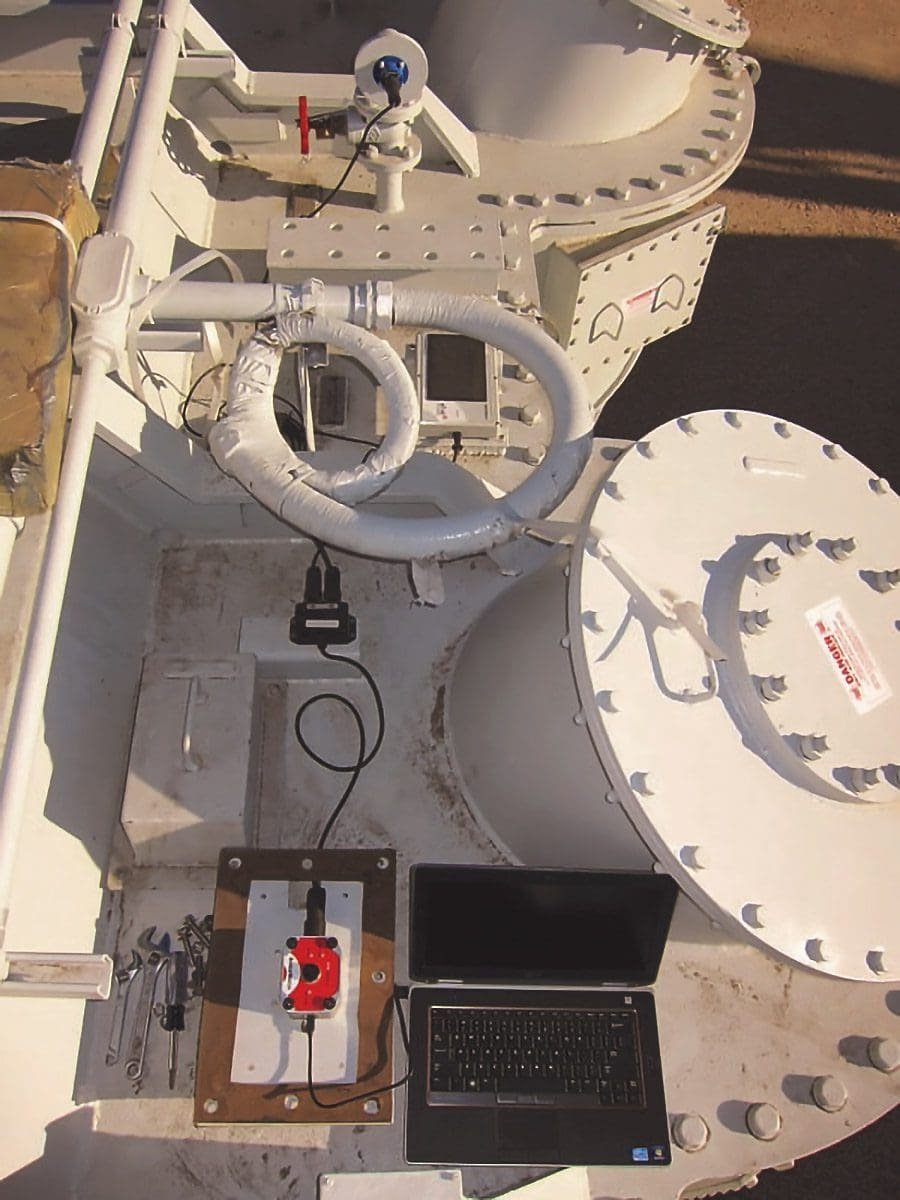

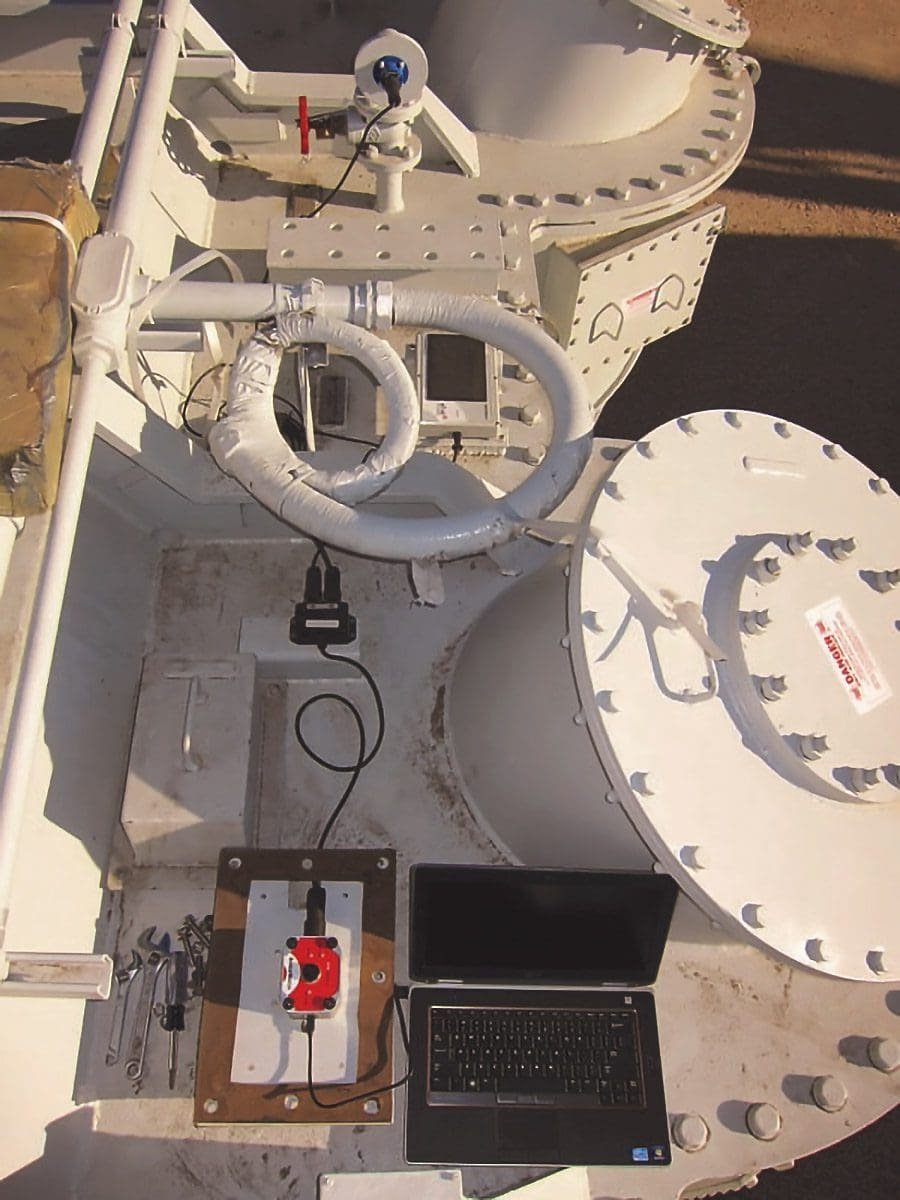

Figure 1 – Shock Watch Digital Fault Recorder

1.1 Function of Impact Recorders

The primary function of impact recorders is to monitor and record any significant external forces experienced by the transformer during transit. The recorder captures data related to the magnitude, duration, and direction of the shocks or impacts.

This information is crucial in assessing whether the transformer’s packaging and protective measures are adequate to withstand the stresses encountered during transportation.

1.2 Importance of Impact Analysis

Impact analysis is an essential step in evaluating the transformer’s condition upon arrival at its destination. By analyzing the data collected by the impact recorder, engineers and operators can assess whether the transformer has experienced any potentially damaging impacts during transit.

1.3 Benefits of Impact Recorders

Damage Detection: Impact recorders provide a clear indication of whether the transformer has encountered damaging mechanical forces during transportation, enabling timely action to address any potential issues.

1.4 Risk Mitigation

By knowing the impact severity, manufacturers and operators can take corrective measures, such as reinforcing packaging or implementing additional protective measures to minimize the risk of damage.

Figure 2 – Twin impact recorder Units Safely Affixed to Transformer for Comprehensive Impact Analysis, the laptop is used to download the data

1.5 Insurance Claims

It’s important to know that in the event of damage during transit, impact recorder data can serve as valuable evidence for insurance claims, expediting the claims process and ensuring appropriate compensation.

1.6 Quality Assurance

The use of impact recorders demonstrates a commitment to quality assurance, ensuring that transformers are delivered to customers in optimal condition.

1.7 Interpreting Impact Recorder Data

Analyzing the impact recorder data requires expertise to understand the magnitude and consequences of the recorded impacts properly. Depending on the recorder’s capabilities, the data may provide insights into the forces encountered at different stages of transportation, such as loading, unloading, and transit.

2. Impact Recorder Empowerment

Strengthening Transformer Transport Reliability and Customer Confidence

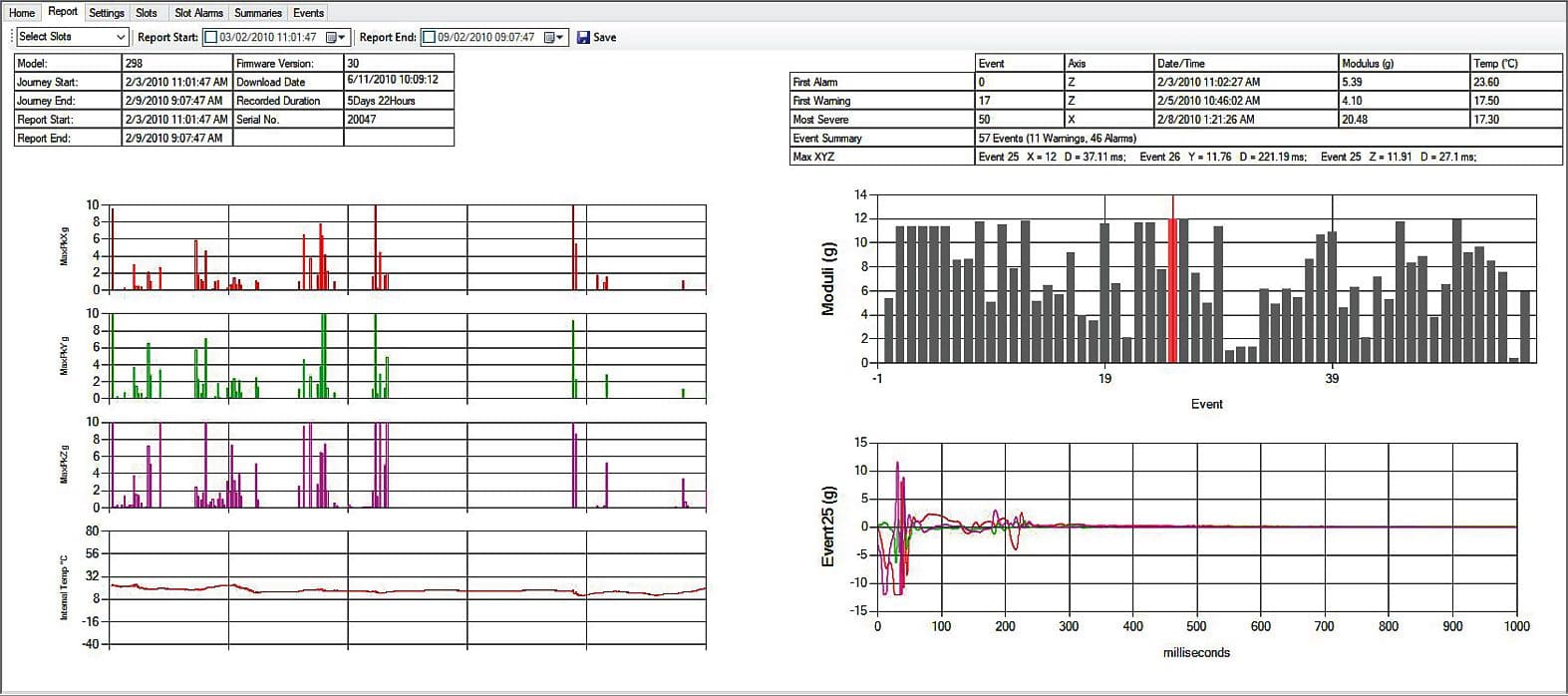

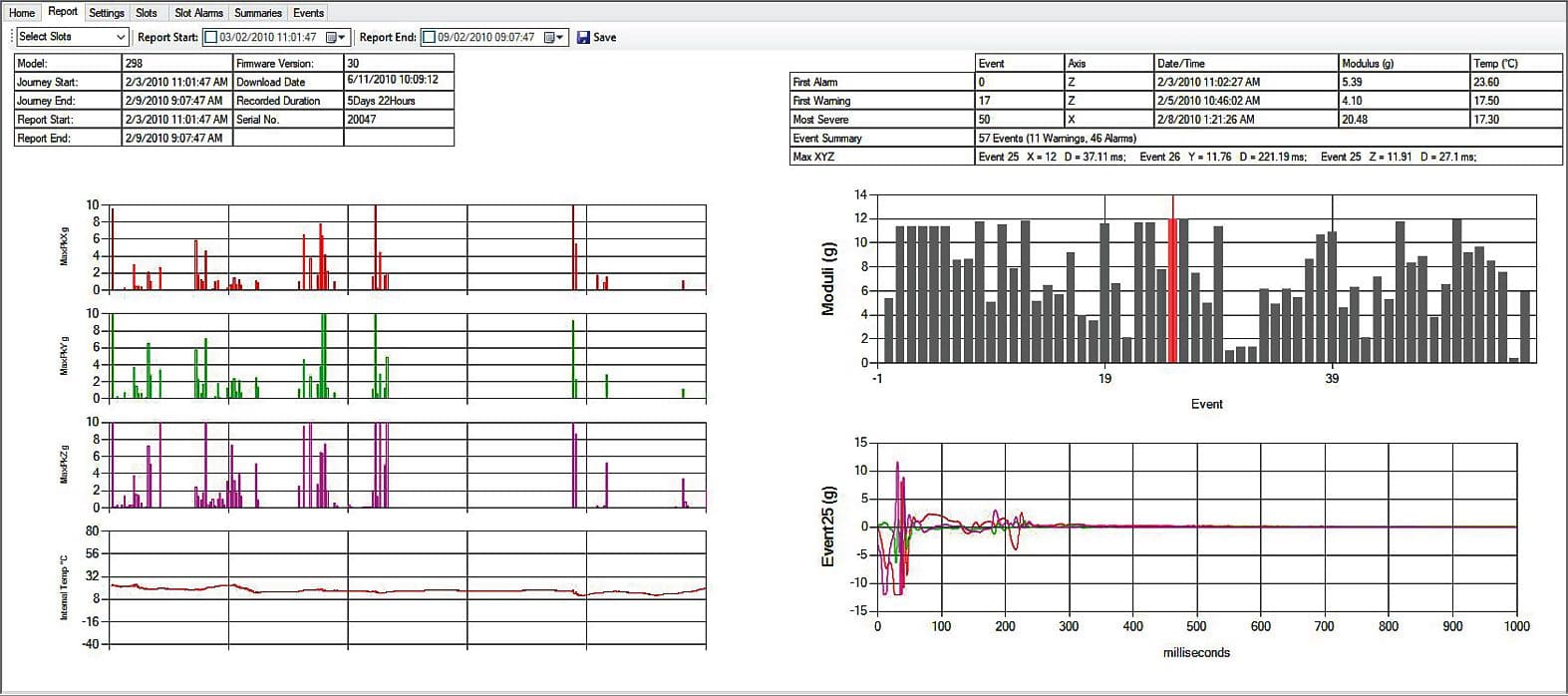

In a specific instance, a transformer was in transit to a client and experienced an impact exceeding the defined 2g threshold. The integrated impact recorder promptly alerted Siemens, leading to a detailed analysis of the impact’s waveform. Upon scrutinizing the data, Siemens discerned that the duration of this impact held the potential to cause harm to the transformer.

In response, Siemens opted for a more comprehensive inspection of the product, aiming to ensure its integrity. Communication was established with the client, apprising them of the potential transit-induced damage and guaranteeing that a thorough assessment would address any concerns.

The absence of the Impact recorder alert could have led to undetected damage or, at the very least, a more protracted and challenging identification process.

Figure 3 – Impact recorder software screen showing that transformer had shock in transport (click to zoom)

3. Nitrogen or Dry Air Pressure Check

Nitrogen and Dry Air Filling for Transport and Storage of Large Transformers

Large power transformers serve as critical components in electrical systems, facilitating the efficient transmission and distribution of electricity. The transportation of these substantial units from the manufacturing facility to their designated installation sites is a complex process that requires careful consideration of various factors.

Among these factors, the choice of internal filling medium, such as nitrogen or dry air, plays a pivotal role in ensuring the transformer’s integrity during transit and storage.

Suggested Video – Checking Power Transformer Nitrogen System

4. Transport Weight Reduction and Storage Considerations

To streamline the logistics of transporting large transformers, manufacturers often opt for the use of nitrogen or dry air as the filling medium within the transformer’s sealed compartments. This choice serves the dual purpose of reducing the overall transport weight and ensuring the preservation of the transformer’s critical components.

The inert nature of nitrogen or dry air minimizes the risk of oxidation and chemical reactions within the transformer during transit, safeguarding its structural and functional integrity.