Fixed or withdrawable medium voltage switchgear?

How to make the right choice between fixed or withdrawable medium voltage switchgear when selecting a new equipment for power substation? The following evaluation procedure should be conducted: Find out how important the additional aspects are.

Weigh up the financial implications and compare this to the additional total cost for a withdrawable system.

Additional aspects that influence the finial decision

When evaluating cost prior to purchase of a new medium voltage switchgear there are few very important aspects that should influence the finial decision. At the end of this article, let’s share the final thoughts about this important topic.

These aspects are less easy to pin point as they are not simply yes or no decisions. Important aspects like:

- Operational friendliness

- Risk reduction

- Visual separation to reduce risk

- Skilled operators

- Site culture

- Maintenance

- Process control and

- Environment

1. Operational friendliness

Medium voltage switchgear should have a user friendly interface. It should be clear, easy, smooth to operate, and good looking. Even though the operators will not directly mention this as an important factor it will certainly be evaluated on a less conscience level.

Most important, is that the operation of the switchgear allows for the switching protocol, that is used on the site were it will be installed. For example – some sites will only allow for a cable voltage testing on an installation with a closed door.

Go back to additional aspects ↑

2. Risk reduction

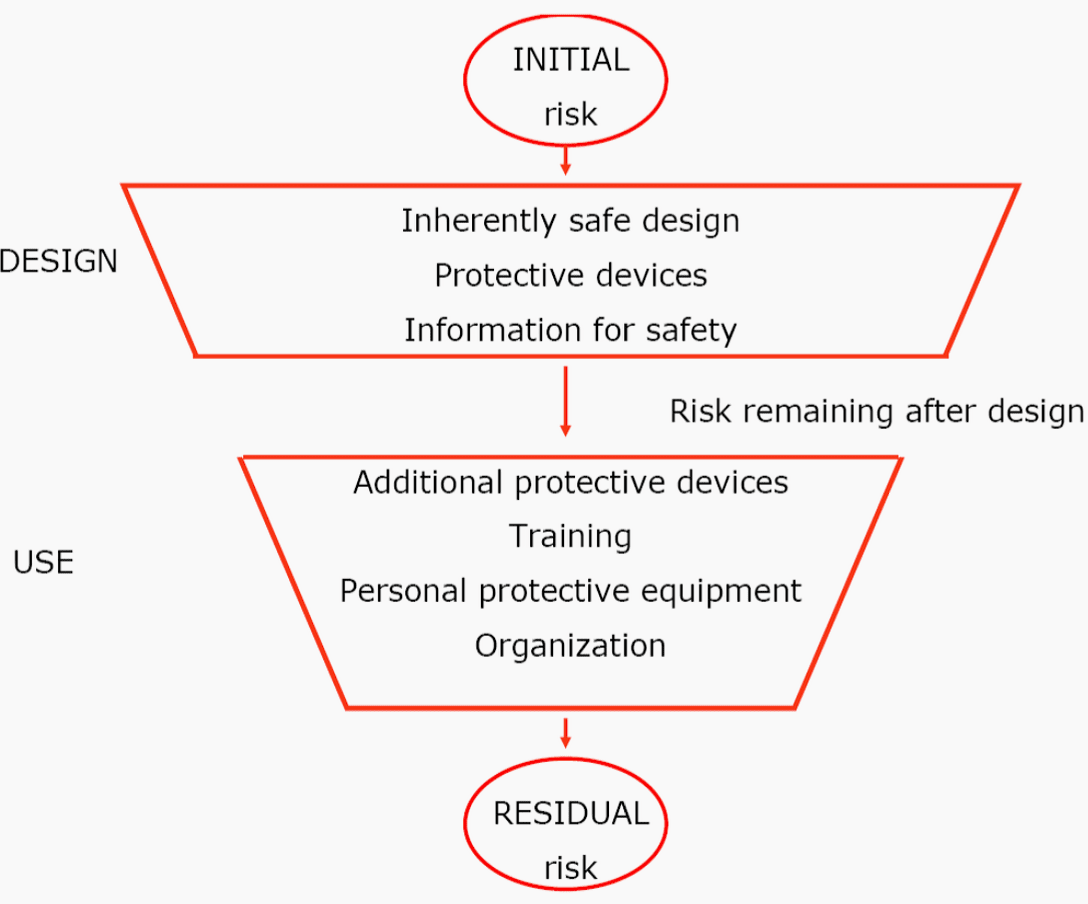

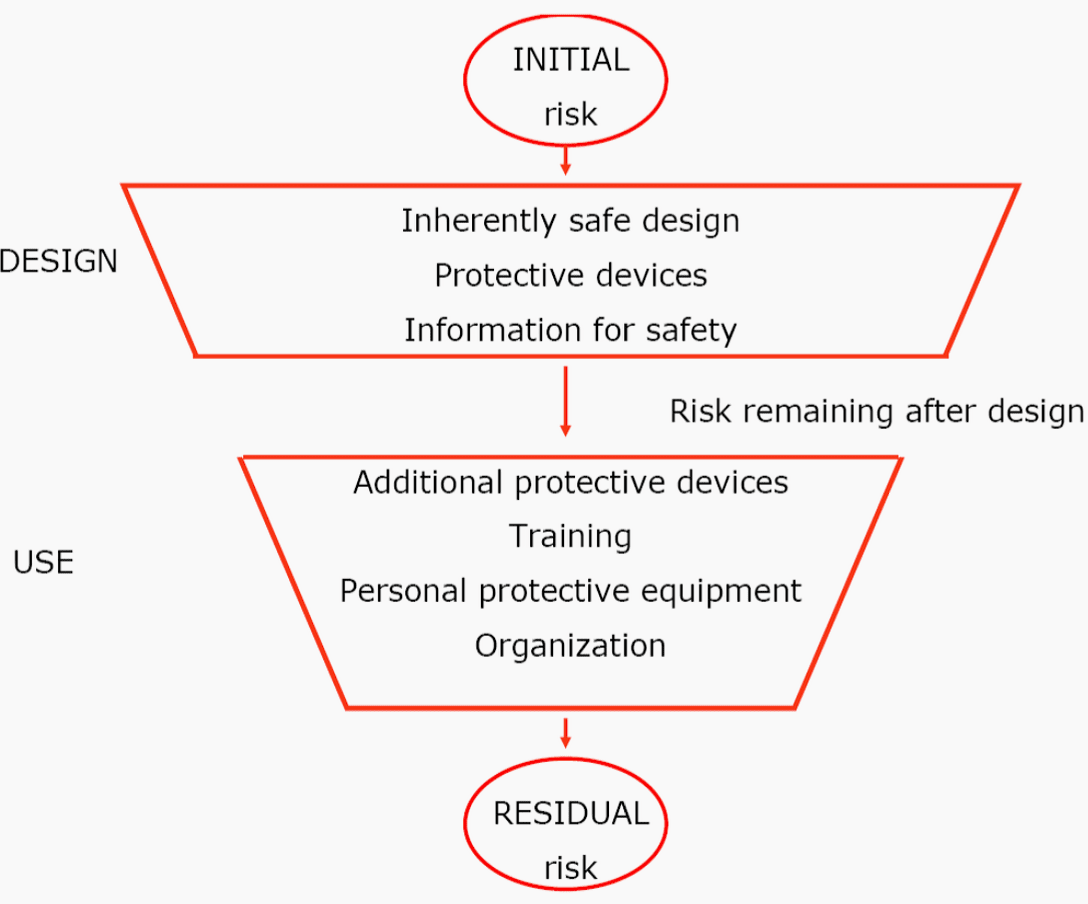

Safety is reducing risk to an acceptable level. The risks of medium voltage switchgear are only partly reduced by requiring a switchgear that conforms to all relevant IEC norms as mentioned under design safety. These IEC requirements do ensure that the switchgear is safe in its design, but a part of the risk occurs during the use of the switchgear.

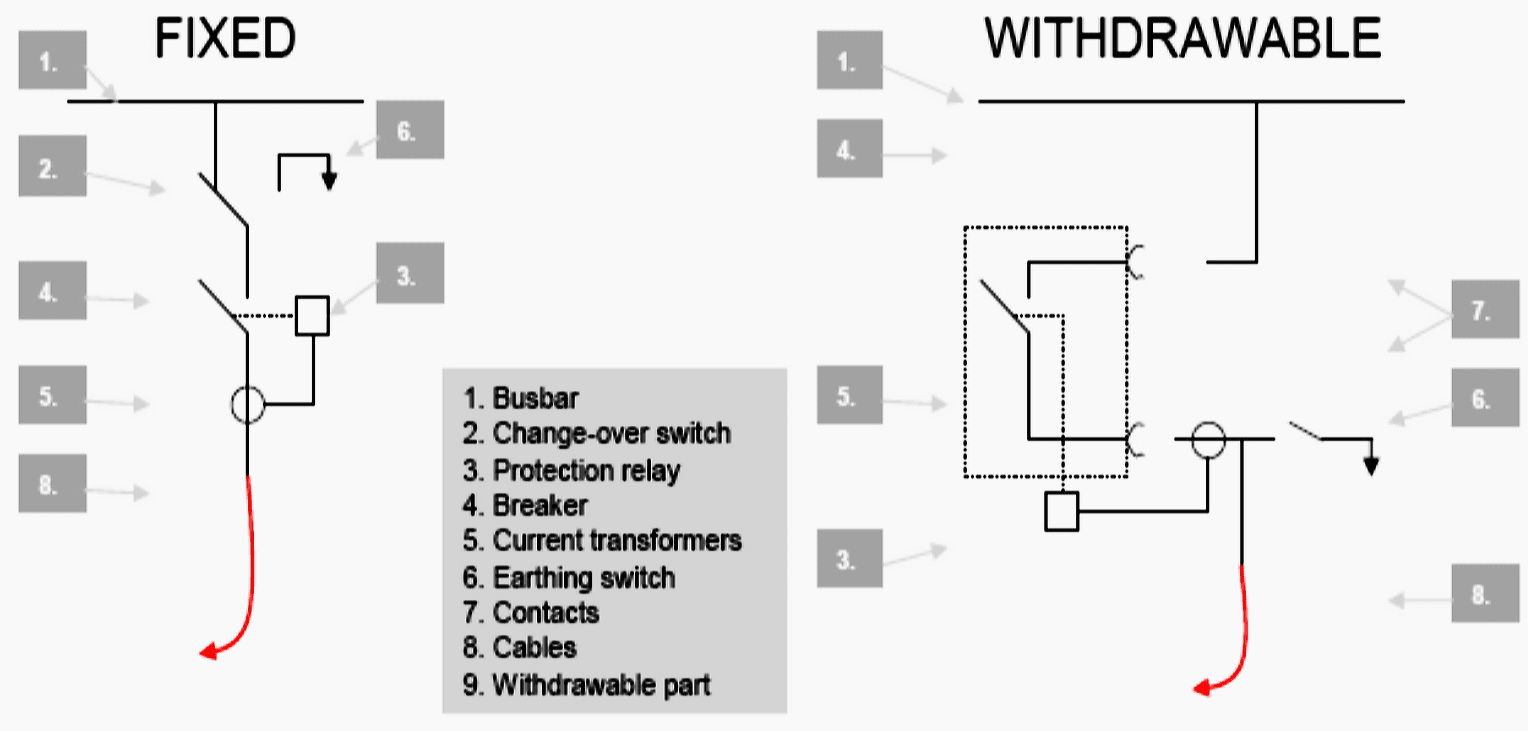

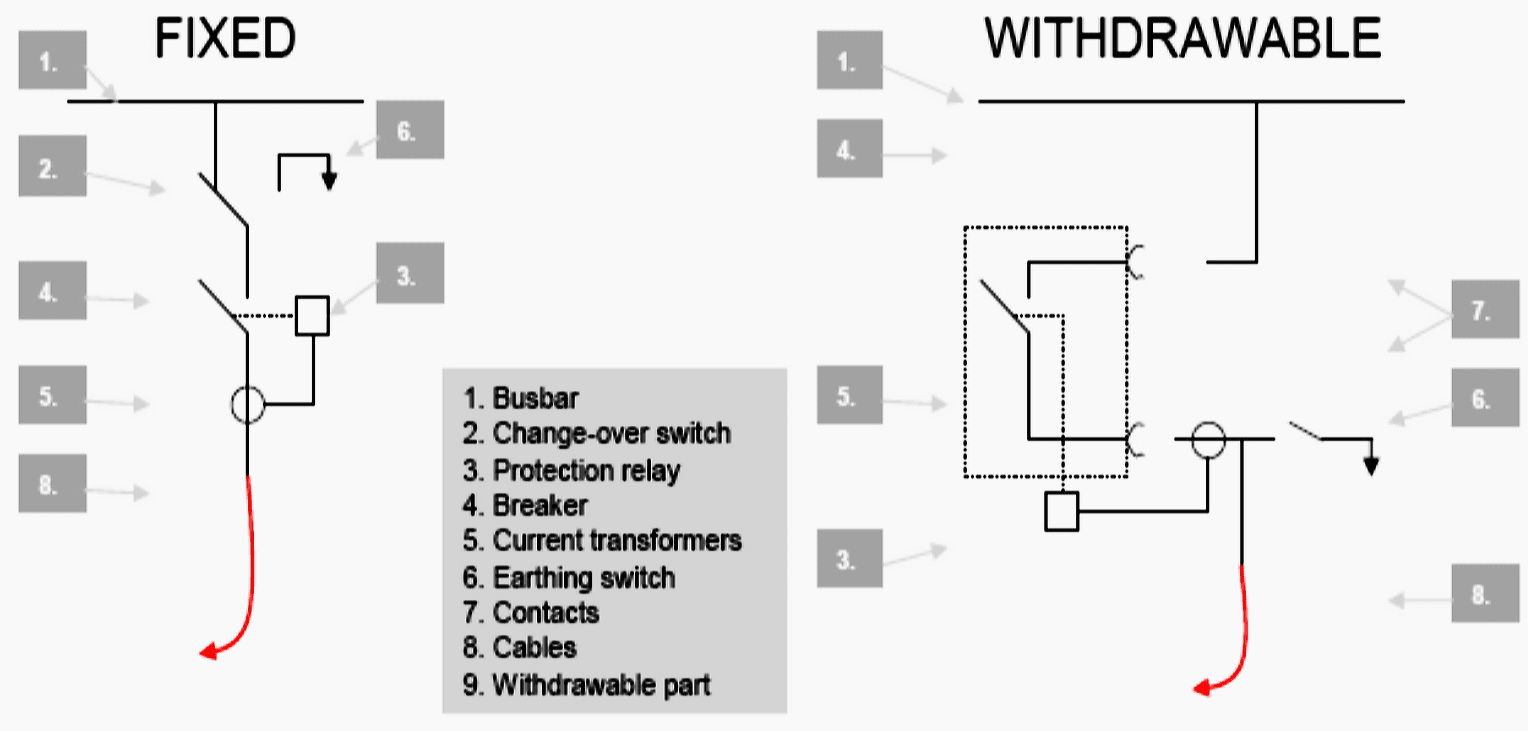

As indicated in Figure 1 below.

To be able to reduce the risks to an acceptable level, the switchgear needs to accommodate any further safety requirements that are needed. These additional requirements can be different per situation.

One of these risk-reducing measures can be the requirement to be able to insert and withdraw a breaker with a close door. A relevant demand since accidents have occurred during insertion of the circuit breaker. Unfortunately the IEC norms as mentioned under design safety only indicate that the “transfer of withdrawable parts” should not reduce the protection level.

Another risk-reducing measure can be the requirement to be able to apply cable earthing simply and safely. The possibilities of reducing the risks to an acceptable level, needs to be evaluated, considering the organization available.

Go back to additional aspects ↑

3. Visual separation to reduce risk

Some users will require a visual separation to be able to reduce the risk. The main advantage of a withdrawable system, is that a clear visual separation of the switching device can be realized.

In earlier days there were configurations with one withdrawable breaker and two positions to connect it. As an alternative for switching one breaker off and the other one on. The whole breaker was moved from one position to another. For instance to choose between two supplies.

This practice insured a safe interlock and it saved money.

Reducing risk by using a withdrawable system for visual separation is a contradiction. It is visually clear that the

downstream equipment is voltage free if the breaker is removed from the system.

But the act of making the visual separation has raised the level of risk?

Certainly compared by the operation of an disconnecting switch in a fixed execution. IEC norms, as mentioned under design safety, do not define “visual separation” but it is clear about giving fail-safe indication of the status of switching devices. Such as an disconnecting switch that is used in a fixed execution.

Go back to additional aspects ↑

4. Skilled operator

There is a culture change going on, with the medium voltage switchgear operators, moving from dedicated switchgear operators to all-round troubleshooters. Up to 20-30 years ago the operator for a medium voltage switchgear was a trained specialized operator. This operators sole task was to perform the switching operations of “his” network.

Many organizations are now requiring operators to also carry out non-operators tasks. Even non-operators are asked to perform operators duties.

Go back to additional aspects ↑

5. Site culture

Each production plant or company have there own site culture. Often a bundling of knowledge, experience and best-practice for there particular use. Although this site culture varies from site to site there are some similarities with in petrochemical industry sites:

Low voltage motor control centers have withdrawable motor startes and high voltage installations are based on fixed breakers.

Medium voltage is less strict. Often sites are standardized on withdrawable installations but if gas filled installations are used it is fully accepted to use a fixed mounted breaker. But other sites will only opt for withdrawable breakers. It is an evaluation between reliability and quick access for maintenance.

Go back to additional aspects ↑

6. Maintenance of MV switchgear

Circuit breakers are mechanical devices, they will fail. It is important to know when they will fail. The most preferable moment of failing of the medium voltage switchgear is after its expected life time. But in those cases were the failure is expected with in the life time, preventive maintenance is required.

To perform maintenance the breaker involved need to be disconnected from the supply. The increasing demand on the availability of the supply makes it hard to organize a planed outage. With a withdrawable system it is possible to perform the maintenance on a breaker with a minimized effect on the total switchgear.

To maximize the advantages of this practice, all parts that need maintenance need to be on the removable part, including those that are likely to fail.

Some withdrawable switchgear have only a withdrawable breaker, leaving other parts behind, such as: voltage transformers, current transformers, protection-relays, earthing-devices, etc.

For maintenance on the fixed part of the main contacts, the withdrawable medium voltage switchgear needs to be de-energized. Similar to the work on an disconnecting switch on fixed medium voltage switchgear.

Required disconnecting frequency

An other maintenance point to take into account is the required disconnecting frequency, how often will the isolated situation be required. The allowed number of maneuvers of a withdrawable breaker is significantly less than the allowed number of open and close of a disconnecting switch in the fixed execution.

Table 1 indicates the need for de-energizing the total medium voltage switchgear when performing maintenance activities. Both for fixed and withdrawable executions.

Table 1 – Need for de-energizing the medium voltage switchgear during maintenance activities

| Maintenance activity Inspection / Replace on | Fixed | Withdrawable |

| Busbar | total | total |

| Withdrawable main contacts | NA | total |

| Disconnecting switch | total | NA |

| Breaker | total (*) | not |

| Earthing switch | total | not |

| Shutters | NA | total |

| Gliders | NA | total |

| Mechanical interlocks on fixed part | total | total |

| Mechanical interlocks on withdrawable part | NA | total |

* some smart solutions provide possibility for changing breakers without de-energizing.

When comparing fixed to withdrawable, the (still) mandatory maintenance and the down time it will cause needs to be weighed against the advantages that are gained, when the down time can be reduced.

Go back to additional aspects ↑

7. Process control

Petroleum and Chemical Industry systems are controlled by a centralized process control. The centralized process control is connected to all devices within the process and in many cases the medium voltage switchgear needs to be connected to it as well.

The costs for centralized process control, are normally related to the number of I/O points. The number of I/O points determine in the hardware required. And number of I/O points establishes the amount of programming hours that are

applicable.

Sometimes even measurements are required to indicate the load. Withdrawable systems have more switching statuses that can be communicated to the centralized process control, and therefore there number of I/O points can be higher. Fixed switchgear do have less switch statuses, and therefore less to connect to a centralized process control. Maybe not the main consideration, but certainly an aspect that can be unexpectedly costly to implement.

On the other hand, a withdrawable switchgear provides a test position, that allows the centralized process control to operate the breaker external from the switchgear. Providing the possibility to test all signals without effecting the energy flow on the site.

Most likely this is only an advantage during start up of a new system!

Go back to additional aspects ↑

8. Environment

Increasingly users have to consider the environmental impact of equipment, both during manufacture and service, as well as after its life time. In respect to the design, of a medium voltage switchgear, the vision “the least number of components, the better” applies.

Because every part must be manufactured and therefore it has an impact on the environment. Furthermore the materials

used, need to be selected carefully. They need to be safe for personnel and the environment – not just during use, but at the end of service life too! So that they can be completely recycled at the end of it’s life without any problem.

Another environmental aspect is the energy losses in the medium voltage switchgear itself.

The primary changeover points are mainly responsible for the energy losses in the medium voltage switchgear itself. A design that uses primary change-over points with optimal surface contacts will reduce the energy losses over these points.

Go back to additional aspects ↑

Final thoughts

The title question was: Withdrawable switchgear past or future? The answer is clearly that the need for withdrawable systems is still there. Withdrawable medium voltage switchgear and fixed medium voltage switchgear do both have their applications possibilities.

Therefore all major switchgear manufacturers do have both executions!

Within the Petroleum and Chemical Industry there is a belief that withdrawable medium voltage switchgear, will be easier to maintain and repair. In return this can result in reduced downtime.

Many users of withdrawable medium voltage switchgear indicate that this is needed for personal safety. Visual separation for maintenance on downstream equipment. Is a withdrawable breaker wagon the best (safest) way to visualize a separation?

Go back to additional aspects ↑

Reference // Fixed or withdrawable MV switchgear? – EATON (Martijn Imming, Herrie Engbersen)

Is a withdrawable breaker wagon the best (safest) way to visualize a separation?

Yes, it is