Maintenance Benefits and Facilities

A. Maintenance Program

A well-executed maintenance program can provide the following benefits:

- Longer life of switchboard and fewer replacements;

- Reduced time on repairs and overhauls, and the option of scheduling them at an opportune time;

- Fewer failures with unexpected outages;

- Timely detection of any undesirable operating conditions which require correction;

- Improved plant performance and increased operating economies

B. Maintenance Records

A maintenance file should be established which should include the following:

- A record of all installed switchboards and their maintenance schedule;

- Nameplate data of all the equipment and its major components, instruction books, renewal parts lists, bulletins and drawings;

- A list of all items which have to be inspected and what adjustments are to be checked;

- A record of past inspections and test results.

C. Maintenance Tests

Maintenance tests are applicable as indicated:

- Insulation resistance tests of the switchboards’ breakers and bus can be useful in determining the condition of the insulation if they are performed regularly. Since definite limits cannot be given for satisfactory insulation resistance, a record must be kept of the readings and comparisons made. Deterioration of insulation and the need for corrective action can be recognized if the readings are progressively lower after each test.

- High potential tests are not required and are not recommended except in special circumstances, such as after repairs or modifications to the equipment that included the primary circuit (bus assemblies).

When such tests are necessary, they may be conducted using 75% of the standard 60-cycle test voltage for new equipment.

Hi-Pot test is a contraction for high potential HV testing. - After the switchboard has been serviced and adjusted, its operation should be checked before it is returned to service. This can best be done by putting the breaker in the test position (if drawout) and operating it with its associated control and protective devices from a separate source or supply.

D. Maintenance Equipment

Adequate maintenance equipment should include:

- Spare parts for at least those parts of the switchboard that are vital to operation. The manufacturer’s recommended list of spare parts can be used as a guide in combination with operating experience to determine variety and quantity of parts to be stocked.

- A well equipped shop with the following:

- A test cabinet or inspection rack for power circuit breakers;

- A source of control power for checking the operation of electrically-operated breakers;

- A selection of test instruments – multimeters, clamp-on ammeters, instrument transformers;

- Lifting means for handling large breakers;

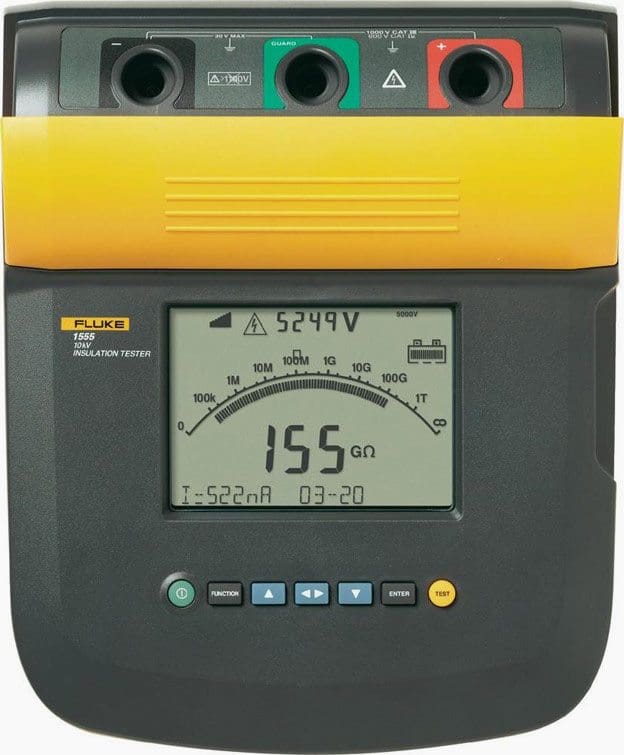

- An insulation resistance tester (Megger™, Fluke™ or equivalent).

E. Safety Considerations

Only authorized and properly trained personnel should be permitted to operate or handle any part of the switchboard.

Maintenance employees must follow all recognized safety practices such as those contained in the National Electrical Safety Code and in Company or other local safety regulations during maintenance.

All of the units of the switchboard to be maintained must be de-energized, tested for potential, grounded and tagged out before removing covers and barriers for access to primary circuits.

F. Frequency of Inspection & Test

It is generally good practice to inspect equipment three to six months after it is first put in service and then inspect and maintain it every one to three years depending on its service and operating conditions. This suggested schedule is only a guide.

Conditions that can make more frequent maintenance necessary are:

- High humidity and ambient temperatures;

- Corrosive atmosphere;

- Excessive dirt and dust;

- High repetitive duty;

- Frequent interruption of faults;

- Older equipment;

- History on preceding inspections

Reference // Switchboard Installation and Maintenance Manual – Industrial Electric Mfg

Hi,

Can you recommend any Chemical to clean Panel Board and Bus bar

many thanks

Hi request a procedure to be followed in detail step by step for LV switch gears during start up and shut down. And trouble shooting procedure..

Thanks

Really this site has been helpful and much more educating. Thanks to its founder. Cheers.

But I have a question: what is the voltage level a 12volts deep cycled battery will be on before replacing it?

Thanks for these good informations.

Thanks!

thanks

Thanks Mr. Edvard. This is very helpful. Thumbs up to you!

Very good Electrical Engineering Portal. Exceptional detailed work and illustrations by founder Electrical Engineer Edvard Csanyi. Great learning tool for a Electrical Technician/Electrical Engineer such as myself. Thanks Edvard and keep up the great work. It is definitly a essential learning tool for every beginning and learning Electrical Engineer.