What is the hazardous area?

The first requirement is to know what a hazardous area is. The principal factors relevant to the classifications of a hazardous area are the nature of the gases or dust present in the potentially explosive atmosphere and the likelihood of that atmosphere being present.

The concept of ‘zone classification’ has been developed to summarize these factors. The nature of the atmosphere is characterized by the chemical composition of the gas or dust and its auto-ignition temperature.

The notions of ‘gas grouping’ and ‘temperature classification’ have been developed to formalize this.

A useful concept is that of the ‘hazard triangle’, Figure 1.

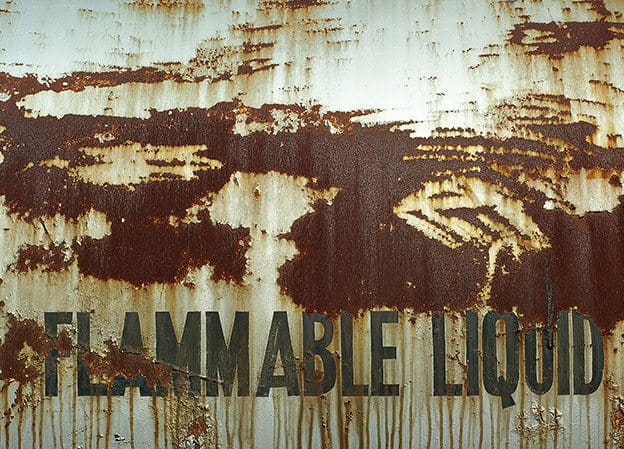

The three sides of the triangle represent fuel, oxygen and a source of ignition, all of which are required to create an explosion. The fuel considered here is a flammable gas, vapour or liquid although dust may also be a potential fuel.

Oxygen is present in air at a concentration of approximately 21%. The ignition source could be a spark or a high temperature.

Given that a hazardous area may contain fuel and oxygen, the basis for preventing explosion is ensuring that any ignition source is either eliminated or else does not come into contact with the fuel-oxygen mixture.

If there is any possibility of oxygen enrichment, i.e. above 20% by volume, then special consideration is necessary to ensure safety.

Zone classification

Table 1 shows the IEC 79-10 zone classification used in Europe and most other parts of the world. The British Standard BS 5345 Part 2 will become obsolete and replaced by BS/EN/IEC 60079-10.

The table also indicates which types of explosion protection are suitable for use within each zone. These explosion protection concepts are described later in the chapter.

In brief, hazardous locations are classified as either Class 1 ‘Division 1’, where ignitable concentrations of flammable gases or vapours may be present during normal operation, or ‘Division 2’, where flammable gases or vapours occur in ignitable concentrations only in the event of an accident or a failure of a ventilation system.

Class II and Class III Divisions 1 and 2 relate to combustible dust and fibres. The 1999 edition of the National Electric Code (NEC) introduced for the first time in the USA the zone classification concept as an alternative to the class and division definitions of hazardous locations, e.g. Class 1 Zones 0, 1 and 2 for gases and vapour.

In the UK, the Factories Act states that where there is a risk of a flammable dust cloud, explosion protection and measures to reduce the risk of ignition will be required.

The ATEX Directive legally requires dust hazards to be considered and classified as either Zone 20, 21 or 22.

Gas grouping and temperature classification

Different gases require different amounts of energy (by hot surface or spark) to ignite them and the two concepts of gas grouping and temperature classification are used in Europe to classify electrical apparatus according to its suitability for use with explosive atmospheres of particular gases.

Table 2 lists common industrial gases in their appropriate gas groups:

Gas group I is reserved for equipment suitable for use in coal mines.

Gas group II which contains gases found in other industrial applications – is subdivided IIA, IIB, or IIC according to the relative flammability of the most explosive mixture of the gas with air.

Table 3 defines each temperature class according to the maximum allowed apparatus surface temperature exposed to the surrounding atmosphere, and indicates common gases for which these classifications are appropriate.

Class 1 is subdivided into four groups depending on flammability:

- A (e.g. acetylene),

- B (e.g. hydrogen),

- C (e.g. ethylene) and

- D (e.g. propane, methane)

Note that when compared with the IEC gas groupings, the subgroup letters are in opposite order of flammability.

North American temperature classification is similar to IEC standards, but further subdivides the classes to give more specific temperature data.

Resource: Newnes Electrical Pocket Book (Get it from Amazon)

Thanks Edvard – it is rare to see the complexity of hazardous area classification reduced to simple fundamentals, this has been done effectively and informatively. Congratulations – we will feature a link to this resource in our new website where we have covered installation guidelines and tips for Electrical Heating In Hazardous Areas https://www.heatingandprocess.com/electrical-heating-in-hazardous-areas/

Dear Edvard

i need information regarding setting for 49 RMS In sepam relay specialy how to define the value of Es0 ??