Special motor control circuits

Ladder logic is often used to implement various motor control circuits. Beside standard motor control circuits, there are also special control circuits designed to allow jogging (brief energization of the motor to adjust its positioning) or to prevent plugging (sudden direction reversal).

Let’s see how these motor control circuits work through ladder logic:

Jogging

Certain types of loads such as presses, cranes, and hoists require their motors be started and stopped repeatedly for very short periods of time to bring the machinery into a specific position. This is known as jogging.

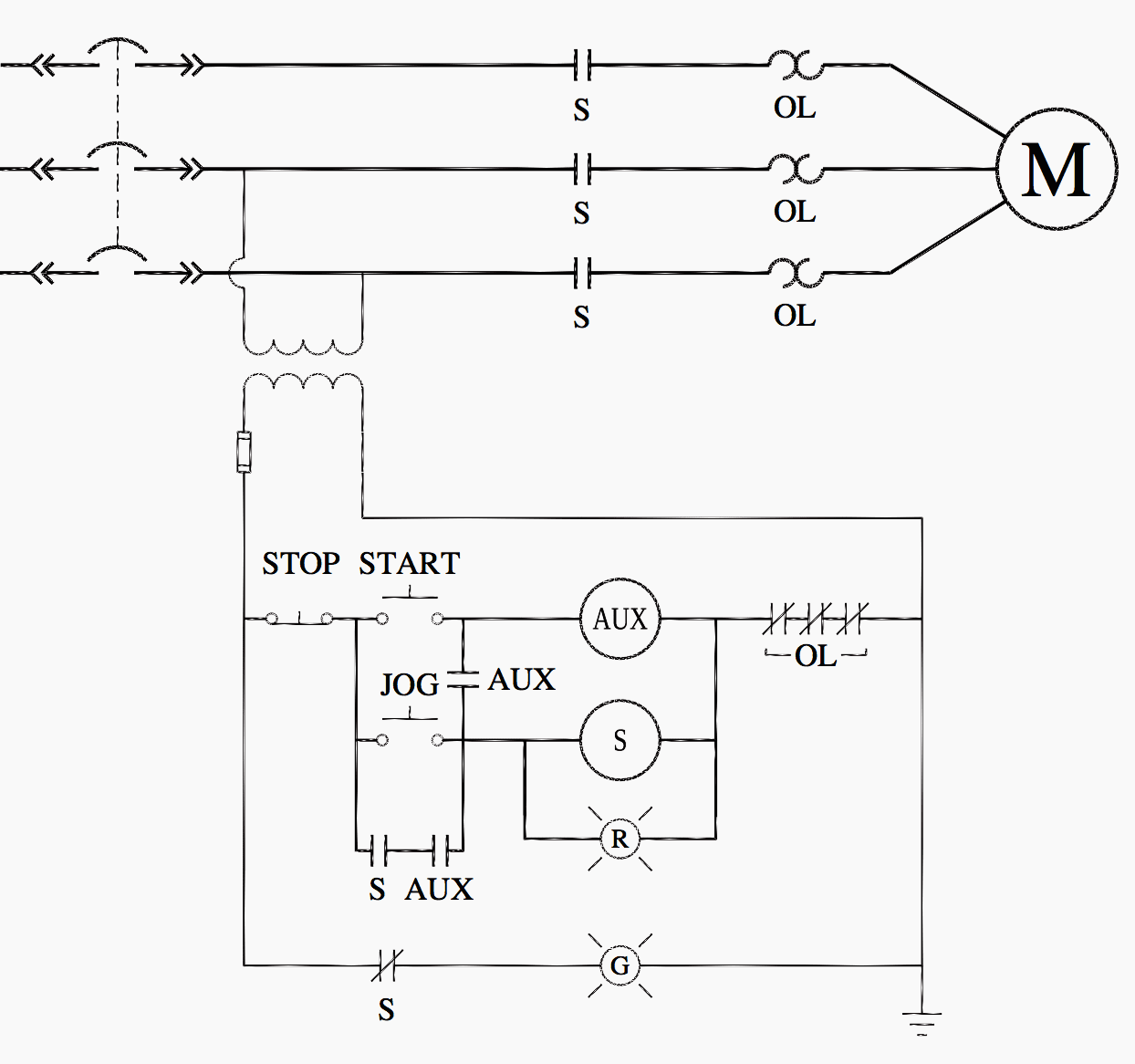

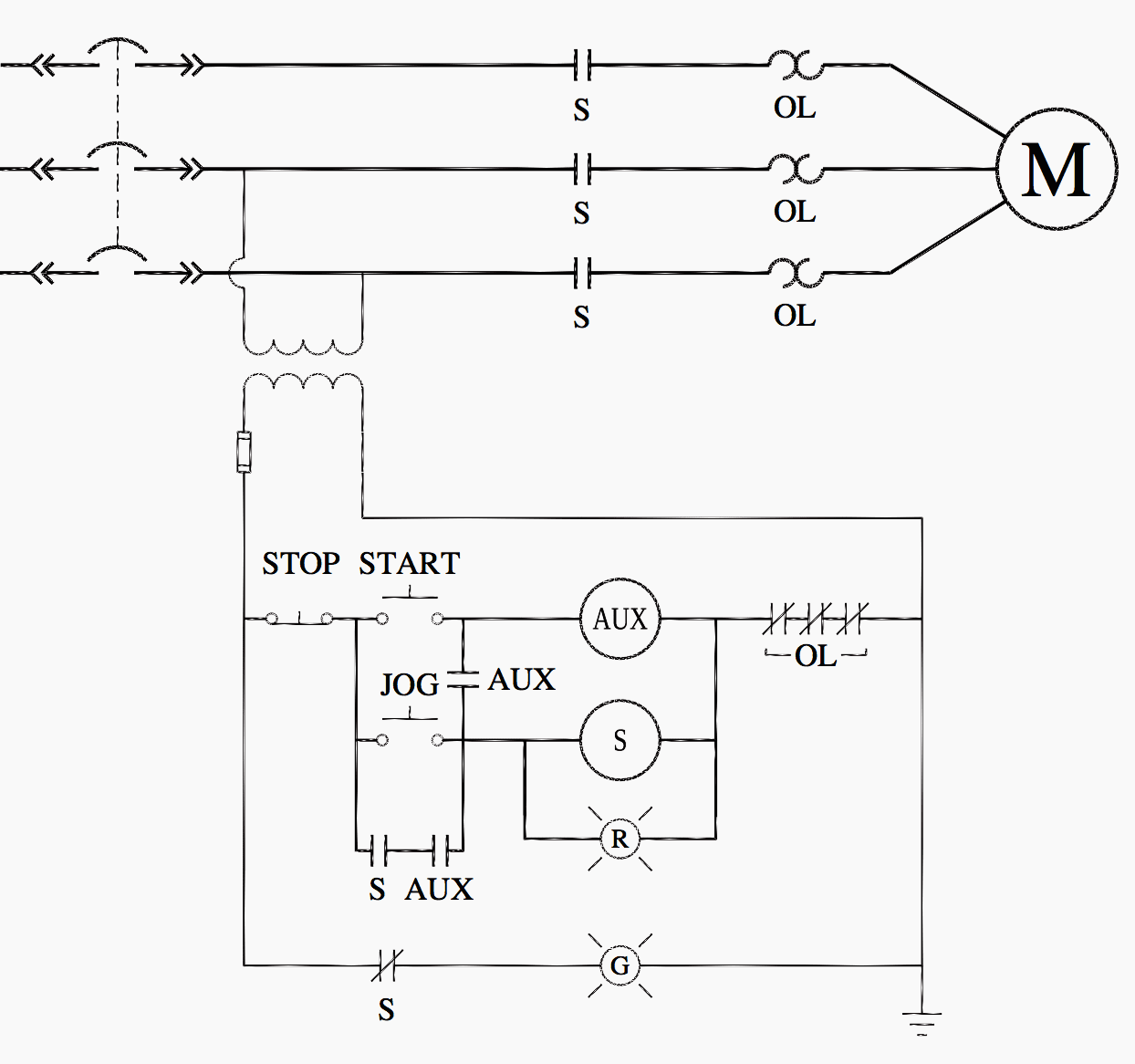

To provide jogging capability for a nonreversing starter, an auxiliary relay can be utilized as shown in Figure 1.

When the JOG pushbutton is pressed, the S coil picks up. This coil closes the contactor for the motor, so the motor starts. When the S relay’s Type A contacts close, the seal-in circuit is not complete because the AUX relay’s Type A contacts are still open. The motor will run only as long as the JOG pushbutton is held closed.

Releasing the START pushbutton will not stop the motor. Pressing the STOP pushbutton, however, will cause both the AUX and S coils to drop out thereby opening the contactors and stopping the motor.

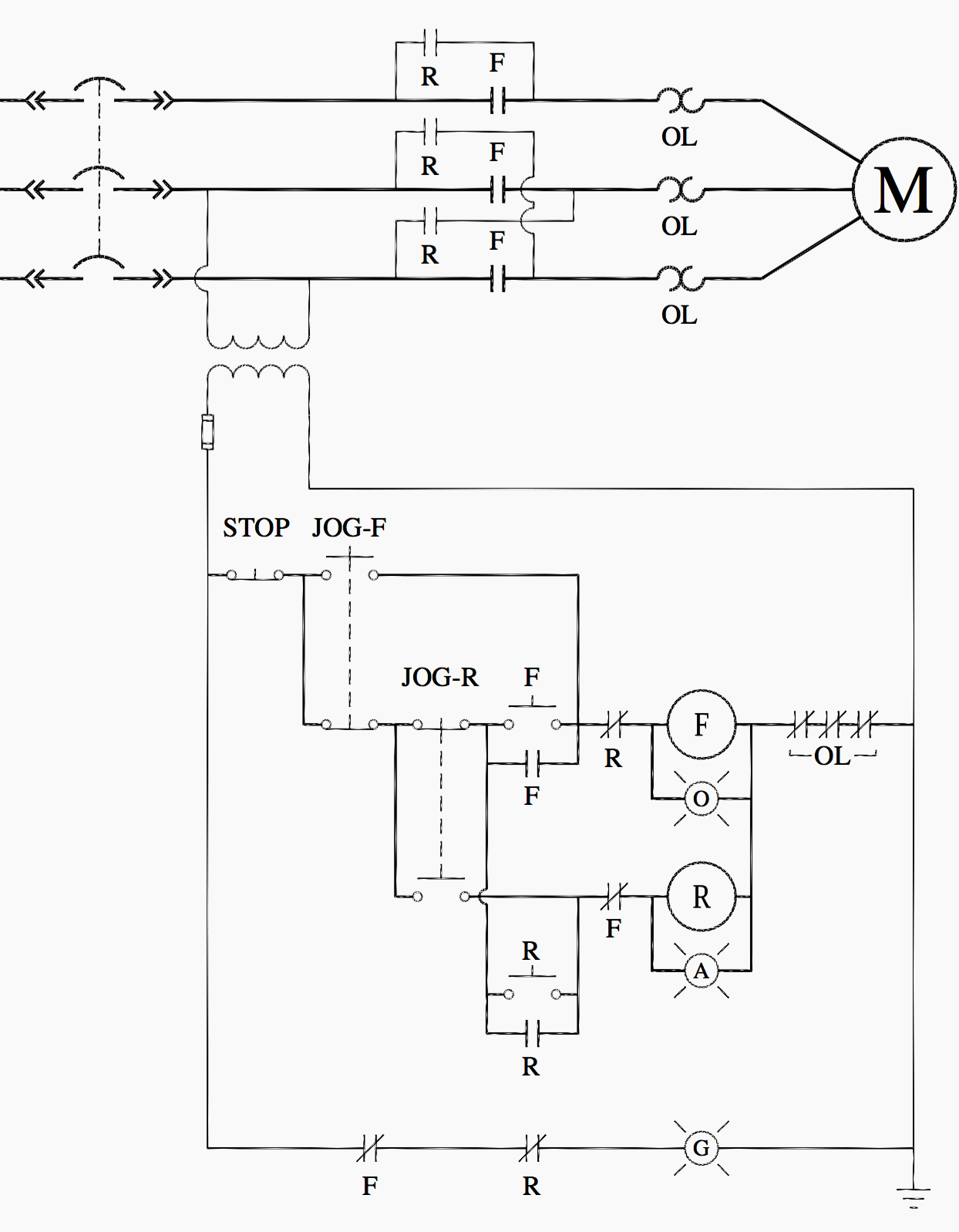

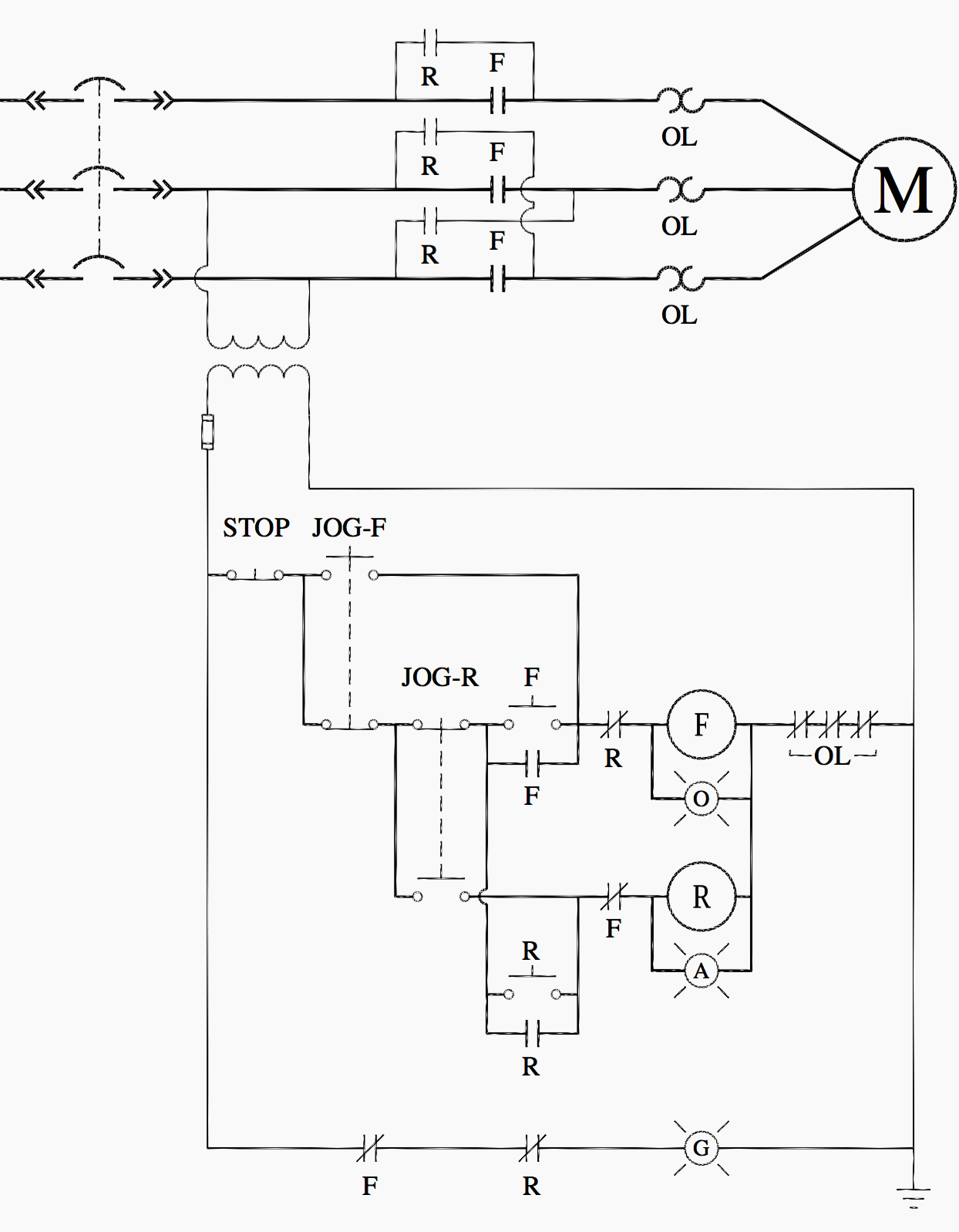

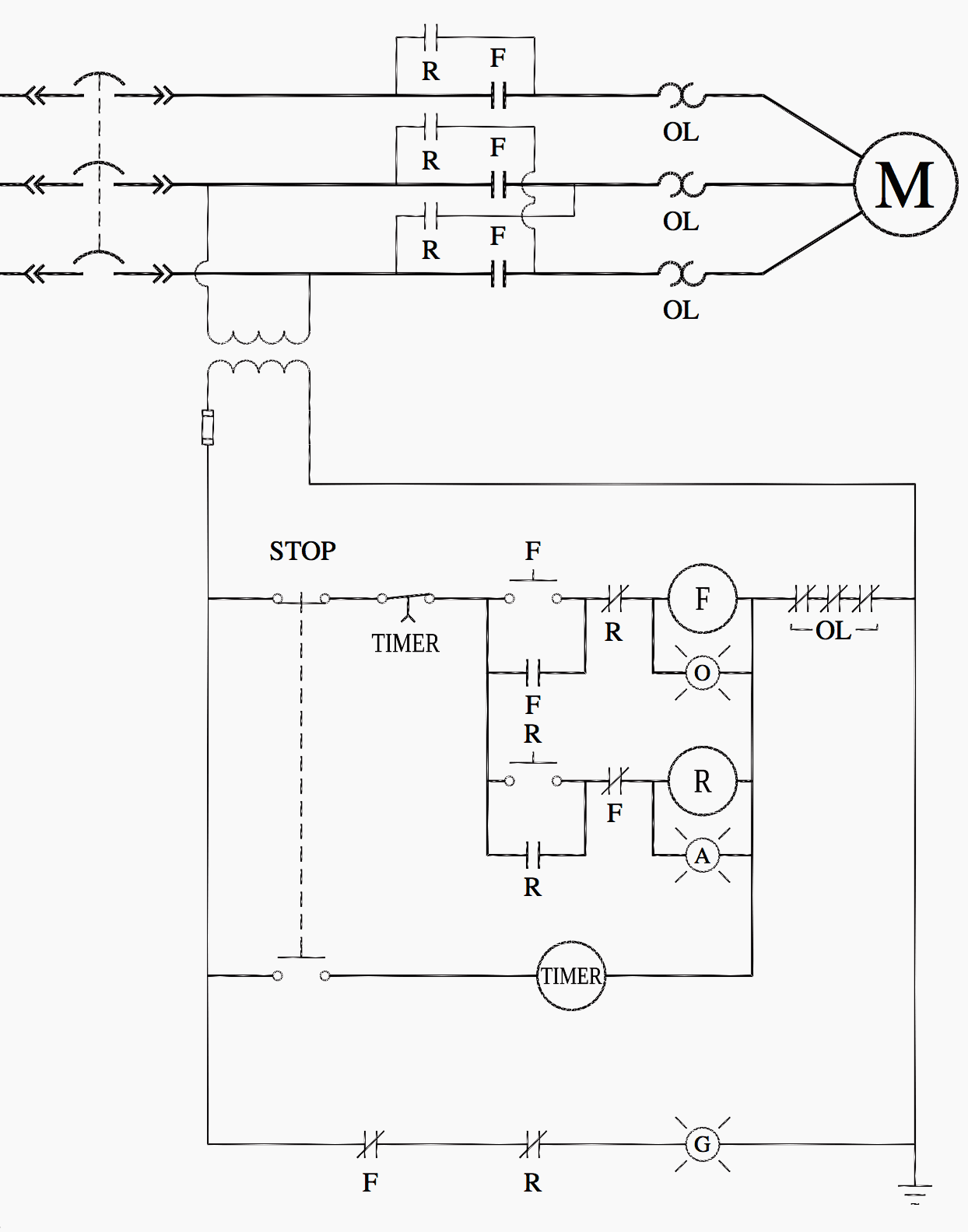

Providing jogging capability for a reversing starter is considerably more complicated, as is evident in Figure 2.

Two contactors are provided for the motor:

- F coil closes the forward contactor and

- R coil closes the reverse contactor.

The jogging function requires gang-operated pushbuttons. When the JOG-F pushbutton is pressed, the F coil picks up and remains picked up as long as the JOG-F pushbutton is held closed. Releasing the pushbutton stops the motor.

Pressing the F pushbutton also picks up the F coil, but when the Type A contacts of the F relay close, the F pushbutton is sealed in. The motor will remain running in the forward direction until the STOP pushbutton is pressed to drop out the F coil.

Pressing the R pushbutton picks up and seals in the R coil. The motor will remain running in the reverse direction until the STOP pushbutton is pressed to drop out the R coil.

Go back to special motor control circuits ↑

Plugging

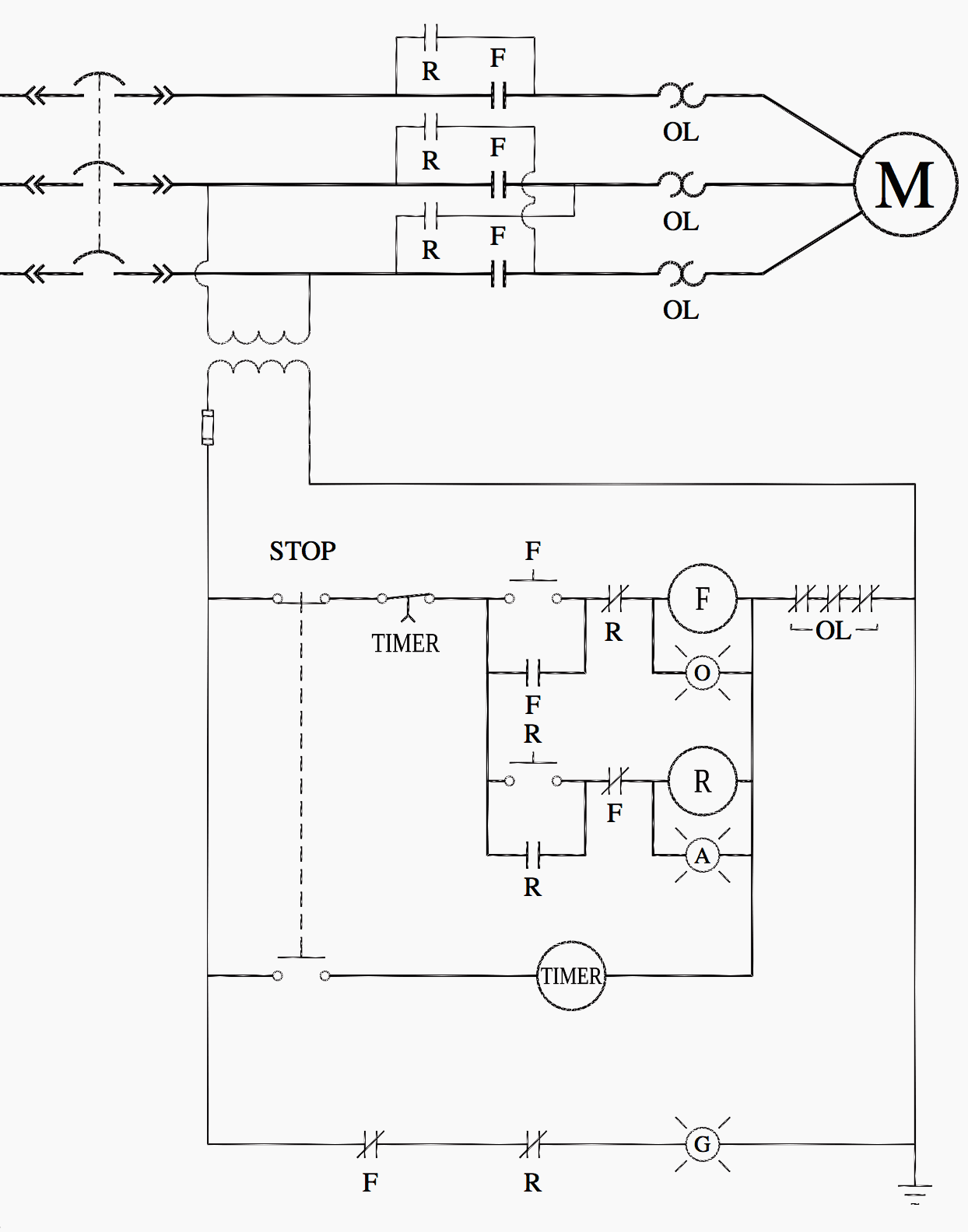

Sudden reversal of a motor’s direction is called plugging. Sometimes plugging is desired, for example, to suddenly stop a motor. In some applications, plugging subjects the driven equipment to unacceptably high torques and must be prevented.

Using a timer in the control circuit, as shown in Figure 3, can prevent plugging. Timers can be purchased with a wide variety of operating characteristics. The timer used in this example is of the delay after pickup type.

Go back to special motor control circuits ↑

Reference // Industrial power distribution by Ralph E. Fehr (Purchase hardcover from Amazon)

I will be very happy when you reply me

Bon sujet merci

Good control schemes and detail.

I think in the third diagram their should be two aditional thinks:

1: a direct wiring from the (400v) fuse to the first pin of the timer contact.

2: a maintien contact (the timer should have an additional contact wired in series with R//F) to permanently energise the timer coil after poshing the stop button, so the timer will start counting to dely the unpluging, than the timer will open the timer contact to permanantly di-energise the coil on hold (F/R).

For more cotion i would suggest a frain diagram.

All of your articles are are very useful, especially for the beginners. I suggest all my juniors to follow your articles.

This would translate readily to PLC logic. Keep up the good work!