Loud transformer humming

The user thinking of loud transformer humming (practically noise) should start at the conceptual stage. If he can, he must consider if he has a noise problem before he specifies his transformer. If he does, a noise survey including frequency analysis would be advisable.

A word of warning here. The noise level as measured and given by the transformer manufacturer is usually for the core and coils inside a cubicle. There is no way that the manufacturer can assess the effect on the transformer noise level by the location in which the unit will be place.

It has come to prominence again, mainly because transformers are placed closer to the populace—in high rise office buildings, apartments, shopping malls and in their gardens.

It is becoming even more necessary to locate these units carefully and some planning, preferably ahead of time, is needed.

It is advisable that if a user wants to maintain a particular noise level in a particular environment they should work backwards.

31 salient points for enclosed transformers

It might be useful to review these 31 salient points and shed some light on practical ways to cut down the enclosed transformer noise.

Point #1

Transformer noise is difficult to change at the source. Flux density reduction is the main thrust, but this means increased cost.

Point #2

Transformer core constructions help to a degree. Reputable manufacturers will use good joints, at steel, consistent thickness, good core supports, few bolts, etc.

Point #3

Transformer current loading has little or no effect on the noise level.

Point #4

Placing transformers in liquid (oil) does not help since oils are incompressible.

Point #5

Vibration – isolating core and coils within a tank does assist vibration isolation although isolation of the whole tank is still needed.

Point #6

Noise reduction by distance is the simplest form of attenuation. If it can be achieved without cost–excellent. Usually it cannot.

Point #7

Noise reduction by screens, bushes, etc., is the next simplest but use should be made of the topography of the site. Remember the shadow effect means the noise could be heard outside the shadow of that screen.

Point #8

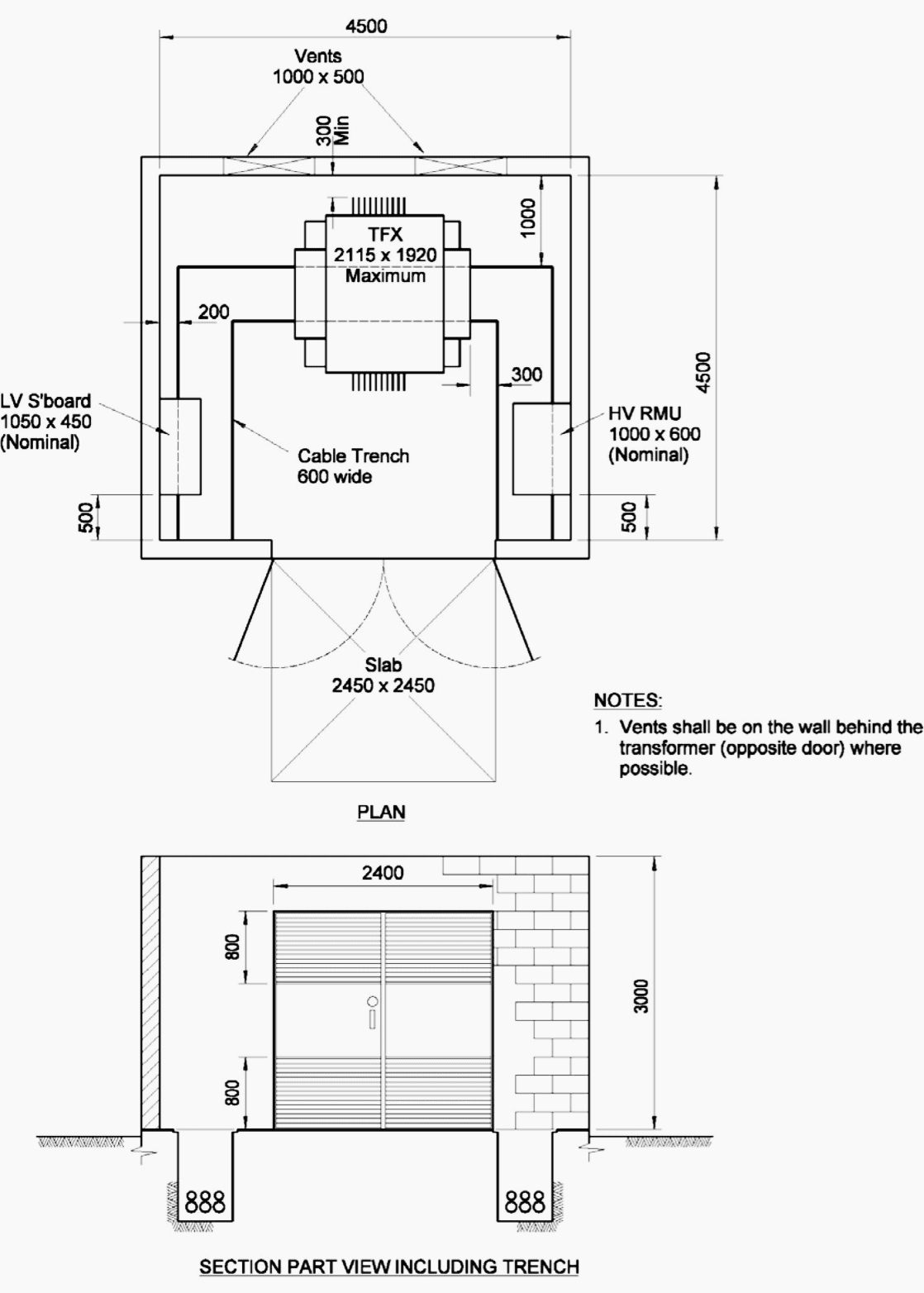

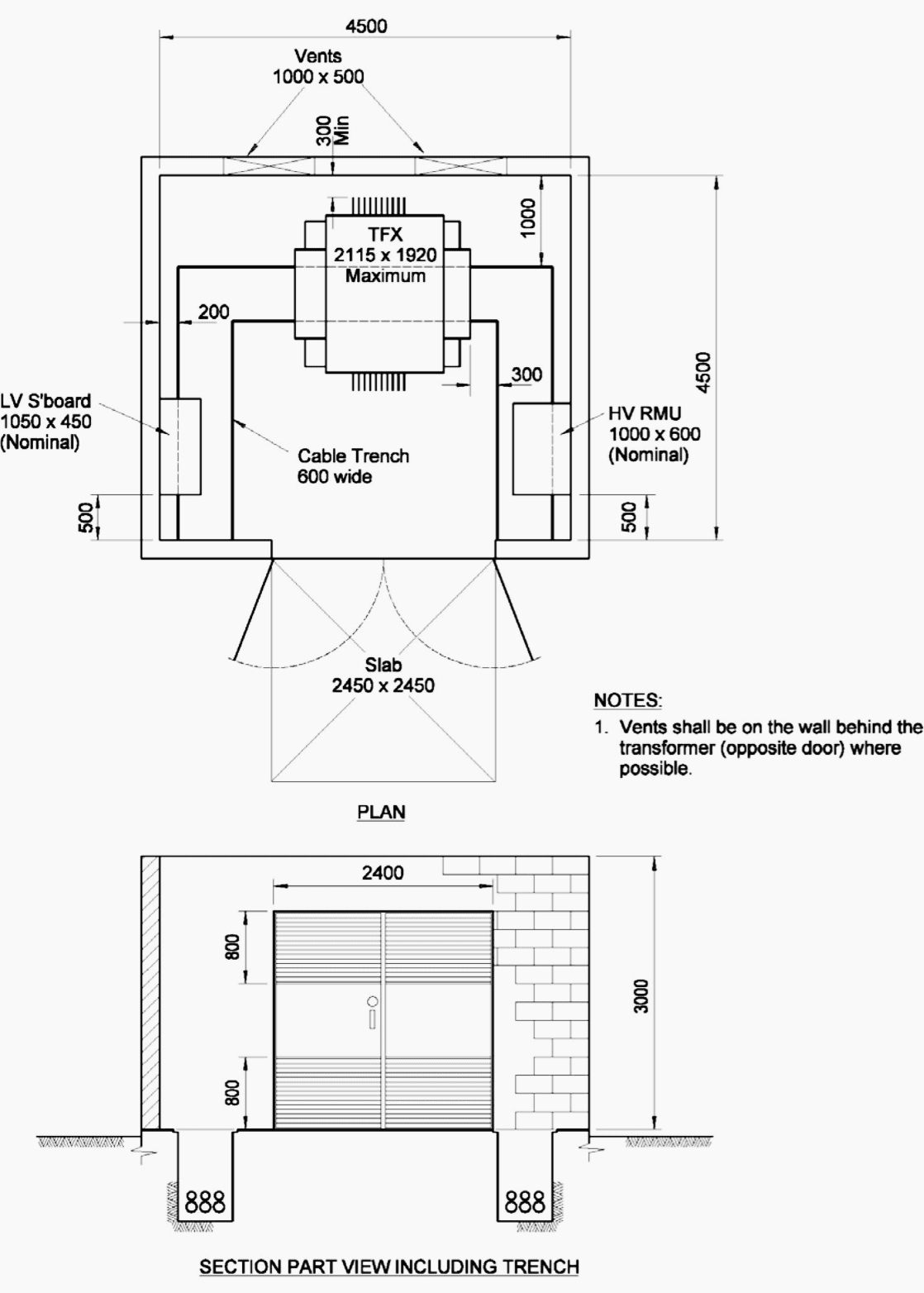

Full enclosure is usually the only option left to a troublesome transformer.

Point #9

Full enclosure can be made of any material with a high mass/weight ratio. Brick, concrete, steel have been used. Expect 25-30dBA reductions.

Point #10

Full enclosures using masonry products are not easily demountable. Prefabricated concrete block is the best for this application.

Point #11

Steel, mass or limp panel techniques make good demountable enclosures. A 15–20dBA reduction is possible with properly designed enclosures.

Point #12

External cooling to the enclosure requires flexible treatments to the connecting pipework.

Point #13

Enclosure mounts should be separate from the transformer base – or at least, isolated somehow.

Point #14

All connections – cables, etc. to enclosed transformers should be flexible.

Point #15

Remember bushings vibrate and losses (acoustic) are experienced through them. Flexible acoustic protection between enclosure and bushings are needed.

Point #16

Bushings used in an enclosure might have to have a longer ground sleeve to accommodate the enclosure roof distances.

Point #17

Pay close attention to access doors and removable covers on enclosures. Tight fits are essential.

Point #18

Watch the dimensions of rooms in which units are mounted. Damp them if necessary, suitable for transformer frequencies.

Point #19

Damping materials are needed if standing waves or reverberations are possible.

Point #20

Choose damping materials compatible with transformer frequencies.

Point #21

If steel plates are used for enclosures ensure that they are gasketed. Isolate the fastening down bolts.

Point #22

Carry out sound surveys before and after installations. Remember to do a frequency analysis so that transformer noise can be differentiated.

Point #23

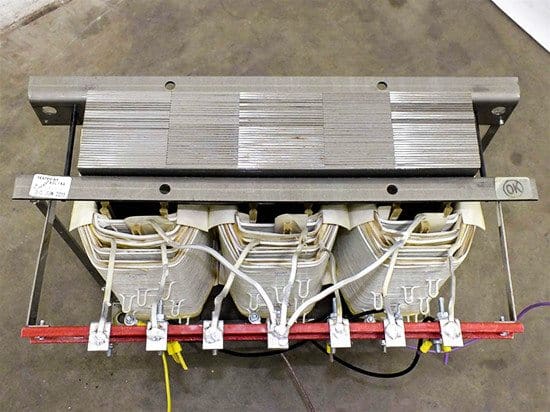

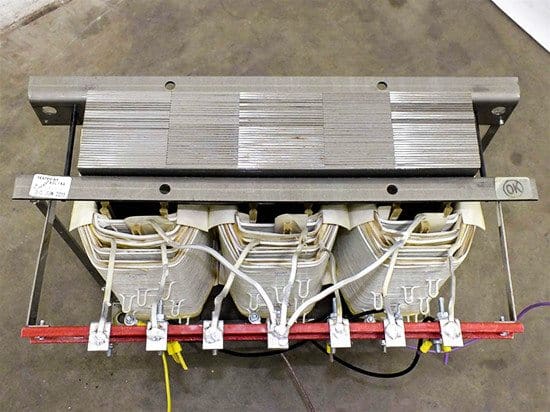

Anticipate transformer noise problems when accommodating them inside a building – especially for dry types.

Point #24

Pay careful attention to removing unnecessary bolting or stiffening used originally for shipping. Make sure the manufacturer identifies what can and cannot be used or removed.

Point #25

Remember transformers need cooling air in rooms. Be careful (acoustically) when you position air ducts, ventilators and grilles, etc.

Point #26

Pay attention to flexible connections inside rooms containing transformers.

Point #27

Make sure the vibration isolators are correctly mounted and will accommodate transformer frequencies.

Point #28

Select rooms which are not near potential complaint areas.

Point #29

Check the voltage on the system. Increased flux density by having a higher than normal system voltage will raise the noise level.

Point #30

When assessing the required noise level of a transformer work backwards from the required noise level at a location. Consider the inefficiencies of the site.

Point #31

Consider very carefully where transformers will be mounted. Resilient structures such as wooden mezzanines might be harmful.

Reference // Understanding Transformer Noise by Federal pacific

excellent post ^^

Excellent article. Thats well presented information. Makes it easier to retain. Would like to see lots more like that

Thanks

Many thanks its really a helpful article!

Thank you very much for what you share !