Low voltage switchgear

The low voltage switchgear involves many devices like power circuit breakers, MCBs, aux. relays, CTs, VTs etc. and of course at the end – enclosures (indoor or outdoor type). The frequency of inspection and maintenance of low voltage switchgear should be 3-6 months when new equipment is installed and 1-2 years for existing equipment.

However, if problems with switchgear are encountered, the frequency MUST be shortened.

Similarly to medium voltage switchgear, the conditions that call for frequent inspection and maintenance are high humidity and temperature, corrosive atmosphere, excessive dirt or dust, frequent fault interruption, and age of the equipment.

The following guidelines are provided for the general maintenance of low-voltage equipment; where necessary it should be supplemented by the manufacturer’s detailed instructions.

8 good tips (guidelines) for inspection and maintenance

The ultimate long-term performance of low voltage switchgear depends on the reliability of its insulation system. An important factor in the insulation reliability is its regular switchgear inspection and maintenance program.

The following guidelines are offered on how to inspect and what to look for when inspecting switchgear. Note that they may also be used for inspecting medium voltage switchgear //

- On energized equipment

- On de-energized equipment

- Specific (hard to see) areas to inspect

- Physical damage

- Heat

- Moisture

- Electrical tracking

- Corona

1. On energized equipment

Three things you should do:

- Listen for popping, spitting, or cracking sounds produced by electrical discharges – also humming noises or vibration produced by resonance.

- With lights out, look for blue or purple corona halos. Orange or red sputter arcs are created by intermittent sparking.

- Ozone – produced by corona or overheating of organic materials, can usually be detected by their odors.

2. On de-energized equipment

Three things you should do:

- Look for physical damage – cracks, breaks, delaminations, warping, blisters, flaking, or crazing of insulated parts.

- Check for foreign objects and loose hardware, warped or distorted insulated bus, and rusty or bent structural framework.

- Powdery deposits, carbon tracks, moisture stains or rust, flaking paint, or varnish are signs that moisture is, or has been, present. Look for probable source of entry.

3. Specific (hard to see) areas to inspect

Although the inspector should check the whole insulating structure, there are a number of specific areas where distress is more likely to occur.

- Boundaries between two contiguous insulating members

- Boundaries between an insulating member and the grounded metal structure

- Taped or compounded splices or junctions

- Bridging paths across insulating surfaces (either phase-to-phase or phase-to-ground)

- Hidden surfaces, such as the adjacent edges between the upper and lower members of split type bus supports, or the edges of a slot through which a bus bar protrudes

- Edges of insulation surrounding mounting hardware – either grounded to the metal structure or floating within the insulating member

Go back to Inspection and Maintenance Tips ↑

4. Physical damage

Broken or cracked insulating supports can allow the supported components to be subjected to mechanical stresses for which they were not designed, resulting in ultimate failure.

Physical damage can stem from several causes:

- Mishandling of the switchgear during shipment, installation, overloading or maintenance

- Mechanical forces induced by heavy faults

- Thermal cycling of insulating members

- Strains induced by improper mounting of insulating members

- Combinations of the above

Go back to Inspection and Maintenance Tips ↑

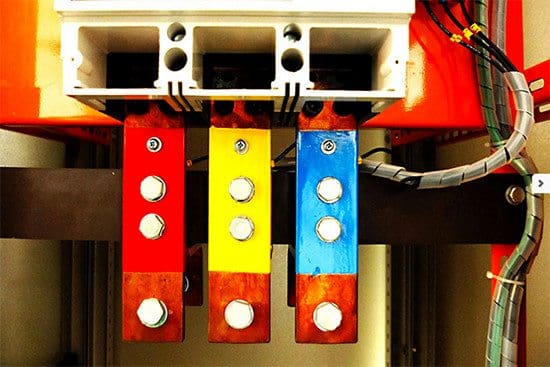

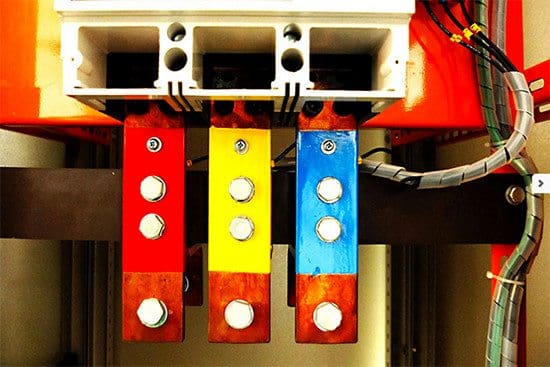

5. Heat

Temperatures (even slightly over design levels) for prolonged periods can significantly shorten the electrical life of organic insulating materials. A prolonged exposure to higher than rated temperatures will cause physical deterioration of organic materials, resulting in lower mechanical strength. Localized heating (hot spots) sometimes occur.

They are hard to detect because the overall temperature of the surroundings is not raised appreciably. Loosely bolted connections in a bus bar splice or void spaces (dead air) in a taped assembly are examples of this.

Since power is usually removed prior to inspection, it is unlikely that apparatus temperature can be relied upon as an indicator of damaging heat. But observed conditions can be used as the basis for determining heat damage. The signs of heating are as follows:

- Discoloration – usually a darkening of materials or finishes

- Crazing, cracking or flaking of varnish coatings

- Embrittlement of tapes and cable insulation

- Delamination of taped conductors or laminated insulation

- Generalized carbonization of materials or finishes

- Melting, oozing or exuding of substances from within an insulating assembly

Go back to Inspection and Maintenance Tips ↑

6. Moisture

The term moisture, usually associated with water, includes vapors which can readily conduct leakage currents. They are often present as air pollutants in industrial atmospheres. The main source of moisture is highly humid air which is subject to climatic type cycling.

Detection of moisture usually depends on signs, rather than the presence of actual moisture.

You should look for these indications:

- Droplet depressions (or craters) on a heavily dust-laden bus

- Dust patterns, similar to those on an auto subjected to a light rain shower after driving on a dusty road

- Deposits which remain if a lm of dirty water evaporates on a at surface

- Excessive rust anywhere in the metal housing

- Actual condensation on metallic surfaces, event hough the insulation is apparently dry

Go back to Inspection and Maintenance Tips ↑

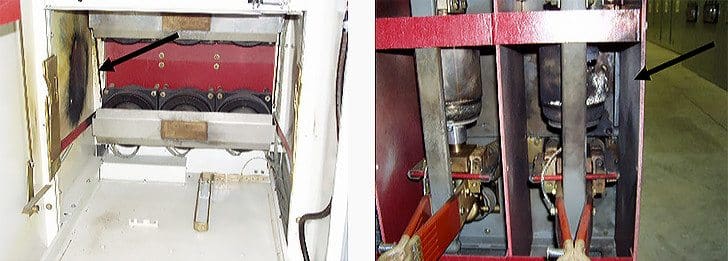

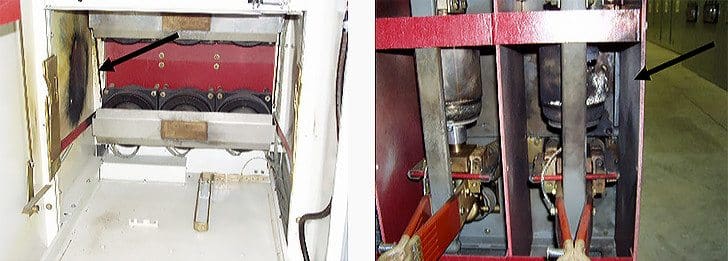

7. Electrical tracking

Tracking is an electrical discharge phenomenon caused by voltage bridging insulating members-phase-to-phase or phase-to-ground. Normally considered to be a surface phenomenon, it can occur internally in some materials.

NOTE! – Materials that are known to track internally are never applied in metal-clad switchgear!

Tracking may be detected in various ways:

- Active streamers or sputter arcs may occur on insulating surfaces adjacent to high-voltage conductors. These arcs are very tiny, usually intermittent or random in nature, and of variable intensity. One or more irregular carbon lines (trees) eroded into the insulating surface is a sign that tracking has occurred.

- Materials specifically designed for track resistance seldom, if ever, exhibit carbon lines. Instead, these materials usually develop erosion craters after extensive bombardment by electrical discharges.

- Tracking can propagate from either the high voltage or ground terminal. It will not necessarily progress in a regular pattern or by the shortest possible path.

These 5 conditions are:

- Appropriate temperature

- High local field intensity or gradient

- Contamination on the insulating surface

- Moisture on the insulation surface

- Susceptible insulating material, forming a bridging link over which leakage current can flow – phase-to-phase or phase-to-ground

Example of tracking problem: Tracking detected on contacts carbon present from recent failure No load on equipment during survey.

Go back to Inspection and Maintenance Tips ↑

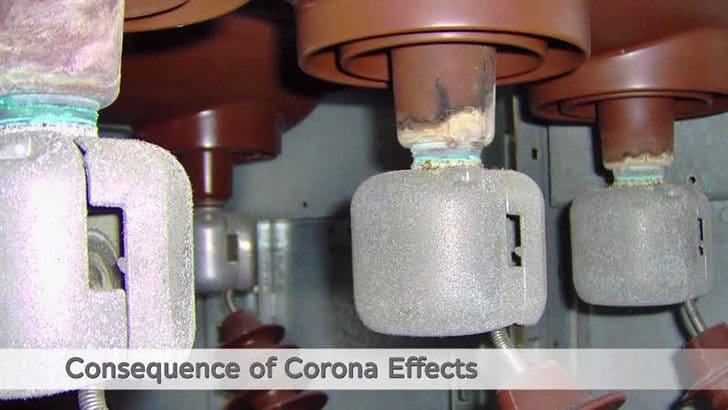

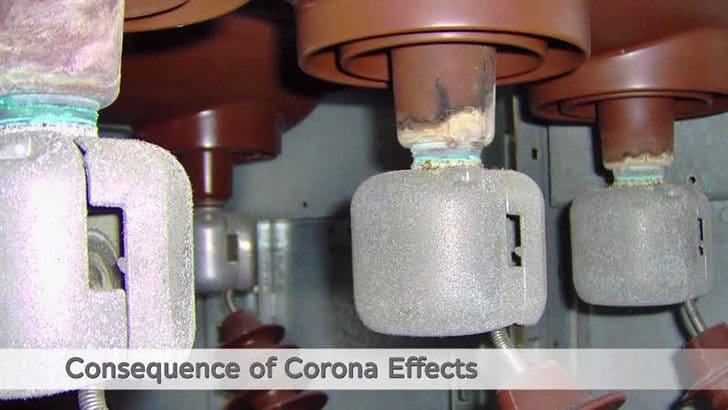

8. Corona

Corona is an electrical discharge phenomenon occurring in gaseous substances. High electrical gradients, exceeding the breakdown level of the gas, lead to corona discharges. Pressure, temperature, humidity, and the type of gas affect breakdown levels.

In metal-clad switchgear, corona (if it occurs) is usually localized in the tiny air gaps between the high-voltage bus bar and its insulation or between to contiguous insulating members or at sharp corners of the uninsulated bus bars.

Corona can be detected in various ways without using instruments as follows:

- A visible, pulsating, blue or purple haze (or halo) may surround the overstressed air gap. The halo is generally of low light intensity and invisible, except in the dark.

- Popping, spitting, crackling, or frying noises may accompany the corona discharge.

- Corona ionizes the surrounding air, converting the oxygen to ozone. It has a distinctive penetrating odor.

- Its presence may be indicated by erosion of the organic materials adjacent to an overstressed air gap. A white powdery deposit is often present along the edges of the eroded area. In some materials, corona deterioration has the appearance of worm-eaten wood.

- Interference with radio reception may be a sign of corona. If the audible noise level increases as a radio is moved closer to switchgear, corona could be the cause.

Problems created by Corona

Corona discharges create problems in a number of different ways:

- Ionization of the air releases ions and electrons. These bombard near-by organic materials affecting their molecular or chemical structure.

- Ozone, formed by corona, is a strong oxidizing agent. It can also react with many materials.

- Nitrogen in the air will also react to ionizing. When ionized under humid conditions, it forms nitric acid which is harmful to insulation.

One important point to consider is that unlike infrared that detects heating due to current flow, corona indicates voltage problems and can be present without current flow. High potential in the electrical field is the major dictating factor for its presence.

Go back to Inspection and Maintenance Tips ↑

References //

- Electrical power equipment maintenance and testing by Paul Gill (Get hardcover from Amazon)

- Corona and Tracking Conditions in Metal-clad Switchgear Case Studies by James Brady – Brady Infrared Inspections, Inc.

A very interesting site that can enhance the knowledge in Electrical Engineering world. Thank you very much.

Waw I like the detail analysis of the atmospheric reaction effects on electrical insulation properties, really marvelous!!

Thank you. Very helpful.

Great post. It’s well-written and well-researched. Keep it up. May I share on my website, please?